Preparation process of phenolic resin-based spherical activated carbon

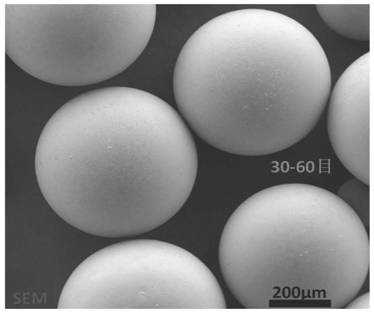

A spherical activated carbon, phenolic resin technology, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of poor adsorption, high impurity content, irregular structure of activated carbon, etc., to achieve uniform carbonization, good controllability of pore size, Smooth and even flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

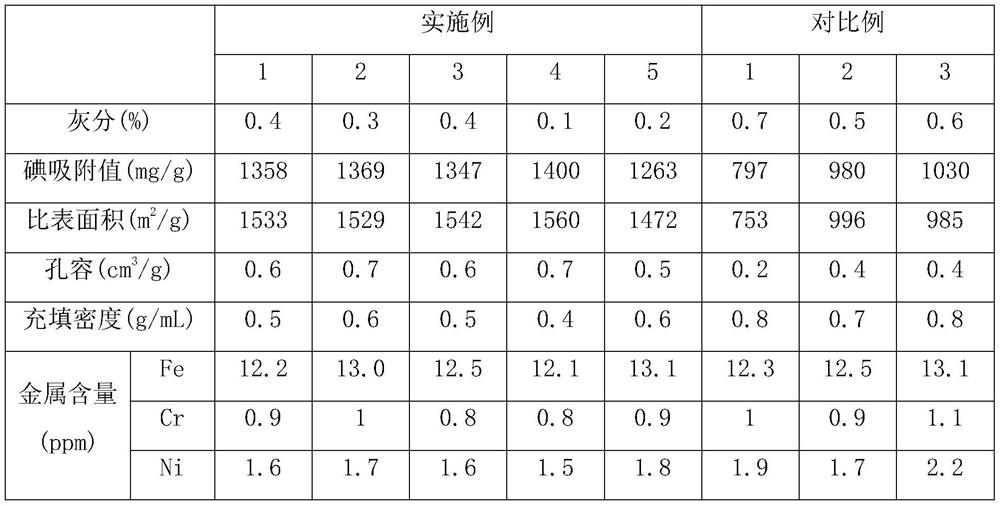

Embodiment 1

[0036] A preparation process for phenolic resin-based spherical activated carbon, comprising the steps of:

[0037] S1, Preparation of phenolic resin microspheres: According to the weight ratio of 1:1:0.01:0.05:4, 200g phenol, 200g formaldehyde, 2g triethylamine, 10g methylenebicyclohexaneamine and 800g deionized water were added to the reactor During the process, the temperature was raised to 120°C to ensure that the pressure in the reactor was 0.2 MPa, and emulsified at 300 rpm for 2 hours to obtain phenolic resin microspheres;

[0038] S2, curing and carbonization: place the phenolic resin microspheres in the quartz hearth of a rotary furnace with a rotation speed of 3r / min, pass in nitrogen for protection, raise the temperature to 150°C at 1°C / min, keep it for 2h, and complete the curing; Under protection, continue to heat up to 600°C at 3°C / min, keep warm for 1h, and complete carbonization;

[0039] S3, Activation: Stop feeding nitrogen, and feed water vapor at a tempera...

Embodiment 2

[0043] A preparation process for phenolic resin-based spherical activated carbon, comprising the steps of:

[0044] S1, preparation of phenolic resin microspheres: According to the weight ratio of 1:2:0.02:0.07:5, 200g phenol, 400g formaldehyde, 4g triethylamine, 14g methylenebicyclohexaneamine and 1000g deionized water were added to the reactor During the process, the temperature was raised to 120°C to ensure that the pressure in the reactor was 0.2 MPa, and emulsified at 300 rpm for 2 hours to obtain phenolic resin microspheres;

[0045]S2, curing and carbonization: place the phenolic resin microspheres in the quartz hearth of a rotary furnace with a rotation speed of 3r / min, pass in nitrogen for protection, raise the temperature to 150°C at 1°C / min, keep it for 2h, and complete the curing; Under protection, continue to heat up to 600°C at 3°C / min, keep warm for 1h, and complete carbonization;

[0046] S3, Activation: Stop feeding nitrogen, and feed water vapor at a tempera...

Embodiment 3

[0049] A preparation process for phenolic resin-based spherical activated carbon, comprising the steps of:

[0050] S1, preparation of phenolic resin microspheres: According to the weight ratio of 1:3:0.03:0.1:6, 200g phenol, 600g formaldehyde, 6g triethylamine, 20g methylenebicyclohexaneamine and 1200g deionized water were added to the reactor During the process, the temperature was raised to 120°C to ensure that the pressure in the reactor was 0.2 MPa, and emulsified at 300 rpm for 2 hours to obtain phenolic resin microspheres;

[0051] S2, curing and carbonization: place the phenolic resin microspheres in the quartz hearth of a rotary furnace with a rotation speed of 3r / min, pass in nitrogen for protection, raise the temperature to 150°C at 1°C / min, keep it for 2h, and complete the curing; Under protection, continue to heat up to 600°C at 3°C / min, keep warm for 1h, and complete carbonization;

[0052] S3, Activation: Stop feeding nitrogen, and feed water vapor at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com