Integrated small sewage treatment device and treatment method

A sewage treatment device, a small technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve problems such as affecting the eutrophication of rural water bodies, and achieve low overall operation and maintenance costs , The effect of compact structure and strong resistance to changes in water quality and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

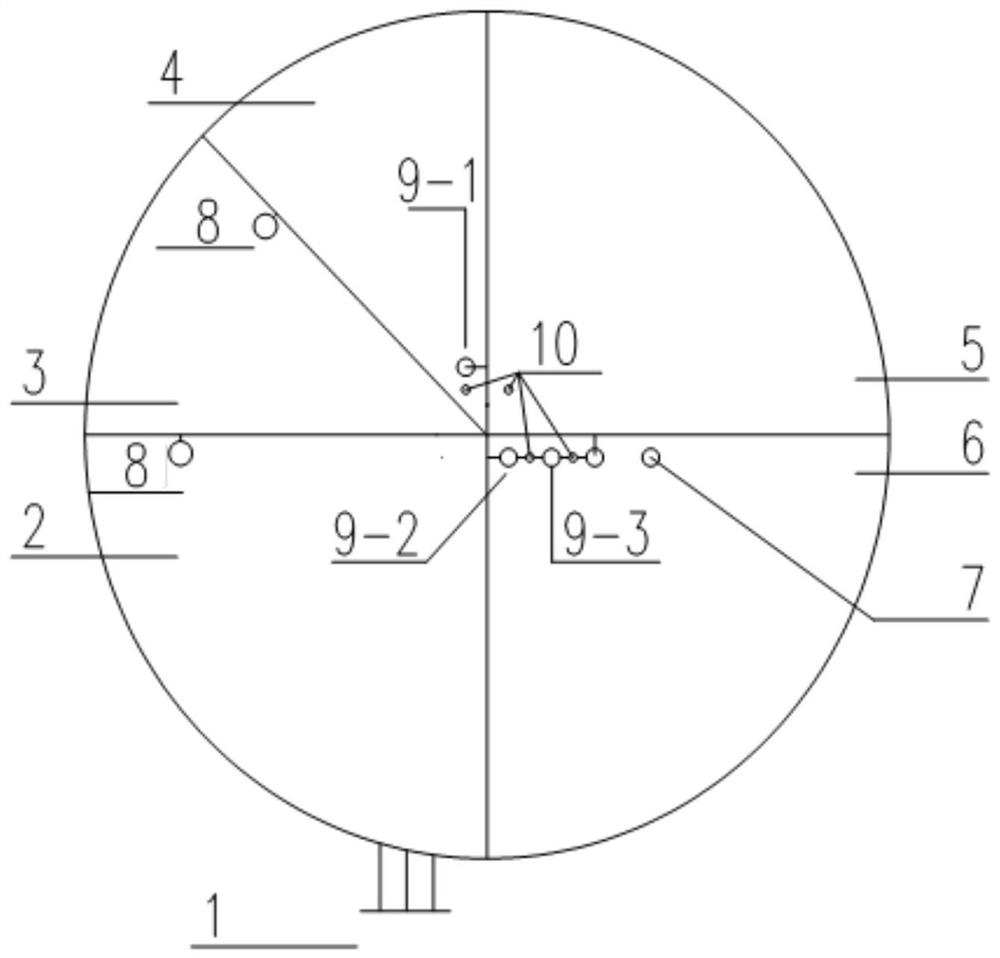

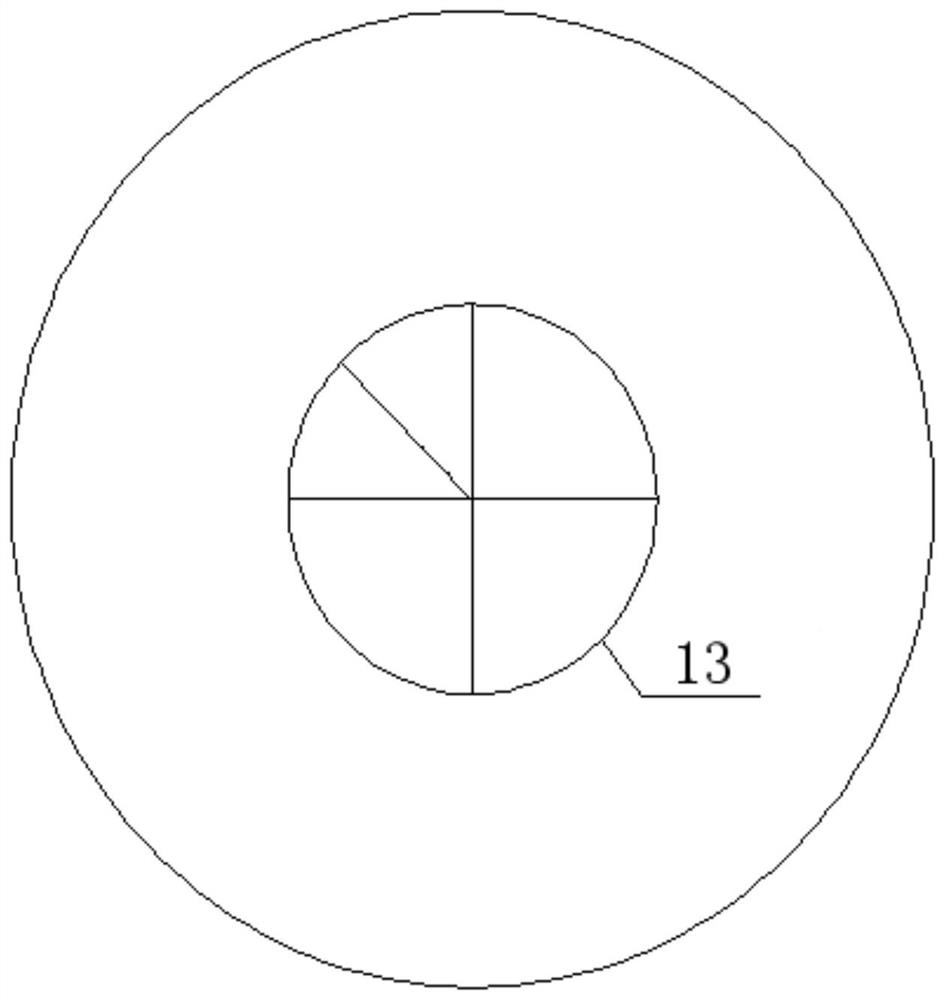

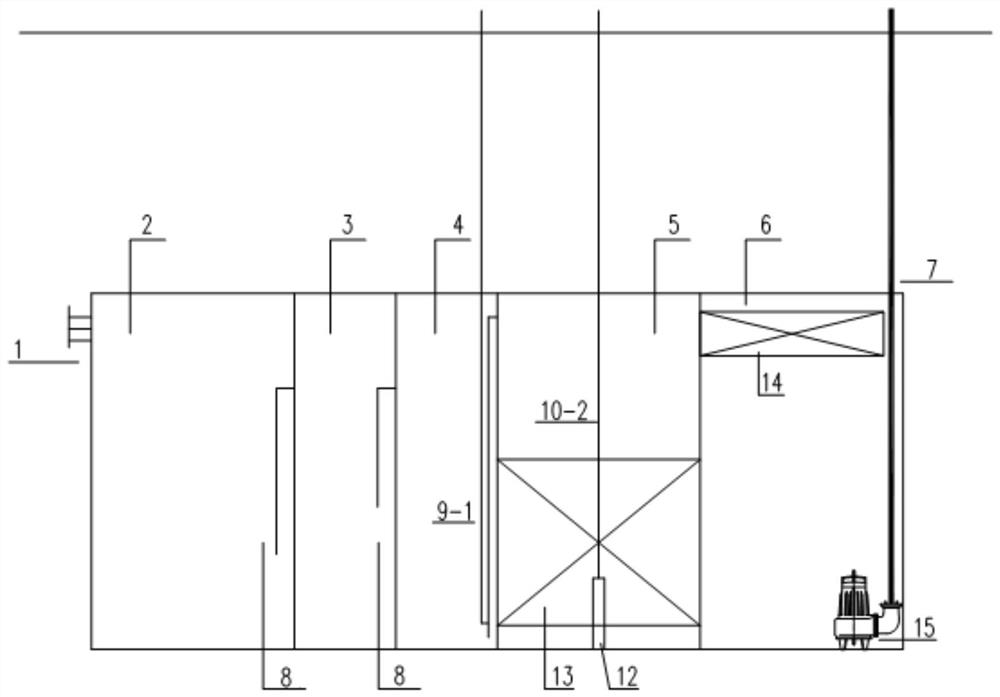

[0028] Specific implementation mode one: as Figure 1 to Figure 4 As shown, the present invention discloses an integrated small-scale sewage treatment device, a water inlet pipe 1, a reaction tank and an electric control box 24; the reaction tank is vertically arranged and has a cylindrical structure, and the cross-section can also be square or oval The cylinder structure is divided into septic tank first area 2, septic tank second area 3, adjustment area 4, biological reaction area 5 and clear water area 6 around the center of the circle through the partition plate (such as figure 1 shown), the top of the reaction barrel is provided with an inspection port 13 (such as figure 2 As shown, each functional unit can be regularly maintained, cleaned and managed through the inspection port 13 arranged on the top, and the deposited solid matter at the bottom of the first zone and the second zone of the suction septic tank); the water inlet pipe 1 and the first zone of the septic ta...

specific Embodiment approach 2

[0029] Specific implementation mode two: as Figure 4 As shown, this embodiment is a further description of Embodiment 1. The first airlift mechanism 9-1 includes a vent pipe 10-1 and a riser 11, and the vent pipe 10-1 and the riser 11 are all arranged vertically, the upper end of the ventilation pipe 10-1 is connected with the solenoid valve 22-1, the lower end of the ventilation pipe 10-1 is connected with the lower end of the riser 11, and the upper end of the riser 11 passes through the regulating valve. The partition between the zone 4 and the bioreaction zone 5 communicates with the bioreaction zone 5 .

specific Embodiment approach 3

[0030] Specific implementation mode three: as Figure 4 As shown, this embodiment is a further description of specific embodiment one. The mud / water alternate discharge airlift system includes a median water passage pipe 17, a connecting inclined pipe 18, a second airlift mechanism 9-2 (for mud discharge) and the third airlift mechanism 9-3 (for extracting sewage after treatment); the upper end of the middle water pipe 17 passes through the dividing plate and the biological reaction zone between the biological reaction zone 5 and the clear water zone 6 5 is set in communication, the lower end of the middle water passage pipe 17 is connected with one end of the connecting inclined pipe 18, and the other end of the connecting inclined pipe 18 is connected with the second air lift mechanism 9-2, and the middle part of the connecting inclined pipe 18 is connected with the second air lift mechanism 9-2. The three gas lift mechanisms are connected to each other by 9-3. Timer 21 con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com