Preparation method of self-activated high-specific-capacitance carbon micro-tube electrode

A technology of high specific capacitance and carbon microtubes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of reducing energy density and hindering the promotion and application of supercapacitors, and achieves simple acquisition and high specific surface area , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

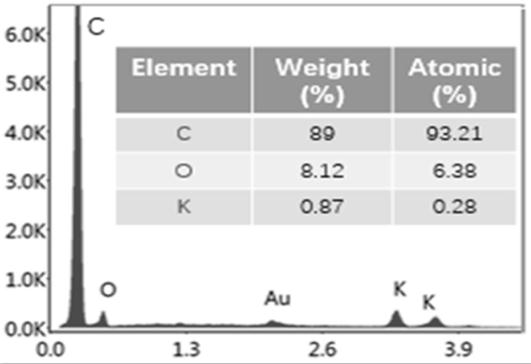

[0025] Take the cones of the phoenix tree flocculant cultivated by potash fertilizer, wash the cones with deionized water to remove impurities on the surface of the cones, and place them in a blast drying oven at 120°C for 24 hours. Cut the cones with a knife, take the fluffy fruit hairs, and remove the seeds to obtain the initial material. The pretreated material is placed in a tube furnace and calcined at a constant temperature of 900°C in a nitrogen atmosphere for two hours. The heating rate and cooling rate are both 5°C / min. After cooling to room temperature, the material is taken out to obtain the desired material.

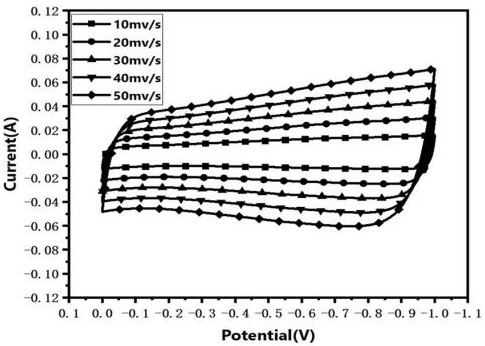

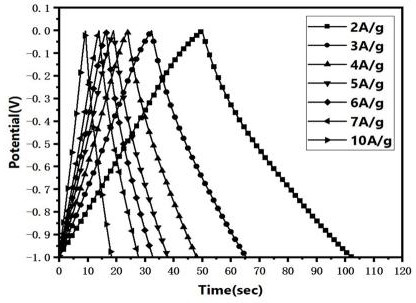

[0026] Divide the sample into three parts, one part for element content test to determine the chemical composition of the material; one part for electrochemical test, in the 6mol / L KOH solution, through the CHI 660E electrochemical workstation, using a three-electrode test system to determine the prepared electrode Material performance; the last one is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com