Novel composite cathode and manufacturing method of all-solid-state lithium battery

A technology of all-solid-state batteries and composite positive electrodes, which is applied in the direction of positive electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as large interface impedance, incompatibility of battery assembly and manufacturing processes, and increased battery manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

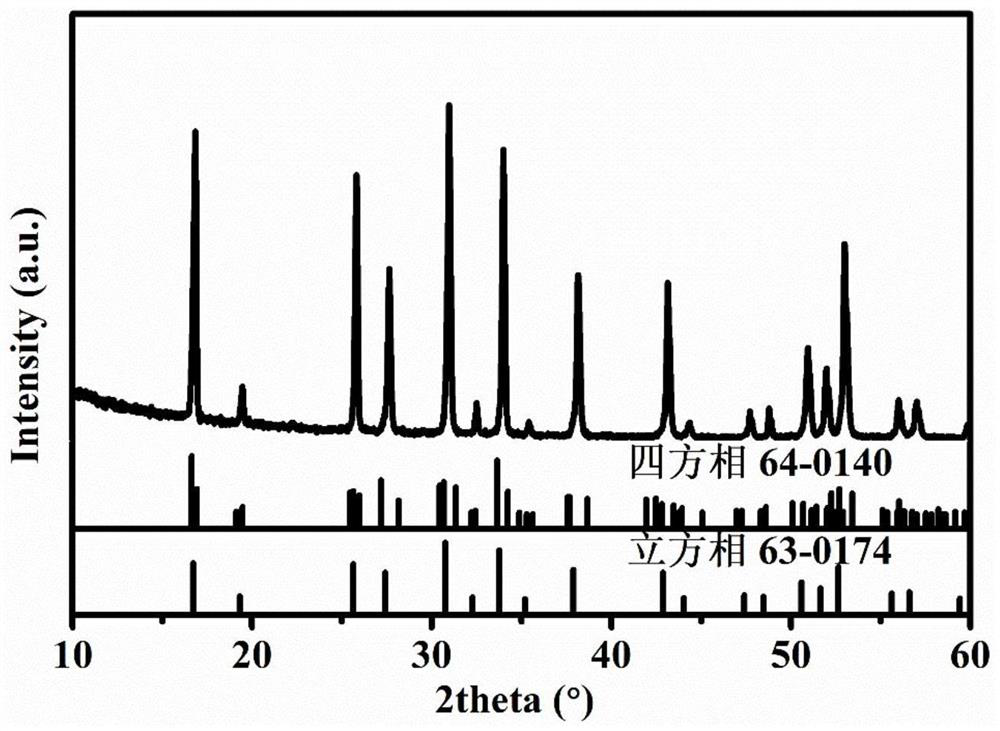

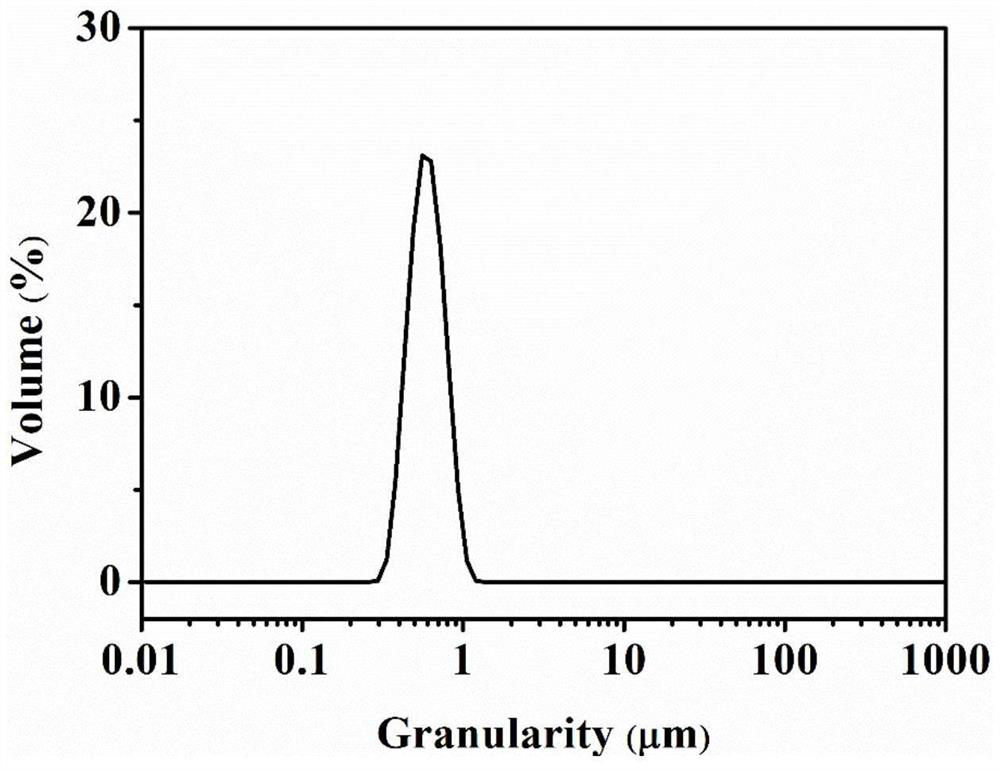

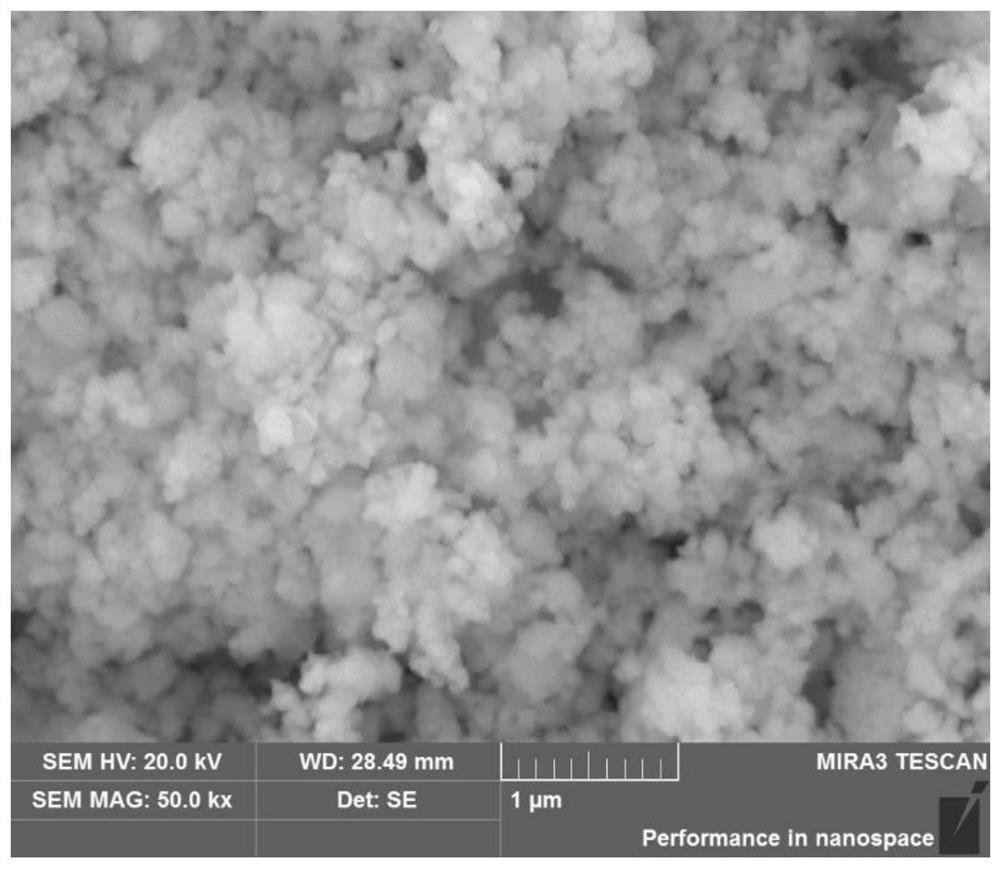

[0065] Lithium hydroxide, lanthanum oxide, zirconia, and niobium oxide were weighed according to the stoichiometric ratio, wherein 6.6 parts of lithium hydroxide, 1.5 parts of lanthanum oxide, 1.6 parts of zirconia, and 0.2 parts of niobium oxide were used to prepare Li 6.6 La 3 Zr 1.6 Nb 0.4 o 12 Powder. Add the above raw materials into a nylon ball mill jar, add isopropanol with a mass ratio of 1.5:1, and yttrium-stabilized zirconia ball milling media with a mass ratio of 5:1, wherein the diameters of yttrium-stabilized zirconia are 3mm and 6mm, and its mass The ratio is 1:1.4. The mixed raw materials were placed in a planetary ball mill for ball milling, the ball milling speed was 800r / min, and the ball milling time was 6h. The obtained mixed raw material slurry was placed in a blast drying oven, and dried at 70° C. for 20 h to obtain mixed raw material powder. Put the mixed raw material powder in a corundum crucible, vibrate the powder and place it in a muffle furnac...

Embodiment 2

[0068] Lithium hydroxide, lanthanum oxide, zirconia, and niobium oxide were weighed according to the stoichiometric ratio, wherein lithium hydroxide was 6.8 parts, lanthanum oxide was 1.5 parts, zirconia was 1.8 parts, and niobium oxide was 0.1 part, to prepare Li 6.8 La 3 Zr 1.8 Nb 0.2 o 12 Powder. Add the above raw materials into a nylon ball mill jar, add isopropanol with a mass ratio of 1.5:1, and yttrium-stabilized zirconia ball milling media with a mass ratio of 5:1, wherein the diameters of yttrium-stabilized zirconia are 3mm and 6mm, and its mass The ratio is 1:1.4. The mixed raw materials were placed in a planetary ball mill for ball milling, the ball milling speed was 800r / min, and the ball milling time was 6h. The obtained mixed raw material slurry was placed in a blast drying oven, and dried at 70° C. for 20 h to obtain mixed raw material powder. Put the mixed raw material powder in a corundum crucible, place the powder in a muffle furnace after vibration, ra...

Embodiment 3

[0071] Lithium hydroxide, lanthanum oxide, zirconia, and niobium oxide were weighed according to the stoichiometric ratio, wherein 6.28 parts of lithium hydroxide, 1.5 parts of lanthanum oxide, 2 parts of zirconia, and 0.08 parts of aluminum hydroxide were used to prepare Li 6.28 La 3 Zr 2 Al 0.24 o 12 Powder. Add the above raw materials into a nylon ball mill jar, add isopropanol with a mass ratio of 1.5:1, and yttrium-stabilized zirconia ball milling media with a mass ratio of 5:1, wherein the diameters of yttrium-stabilized zirconia are 3mm and 6mm, and its mass The ratio is 1:1.4. The mixed raw materials were placed in a planetary ball mill for ball milling, the ball milling speed was 800r / min, and the ball milling time was 4h. The obtained mixed raw material slurry was placed in a blast drying oven, and dried at 70° C. for 20 h to obtain mixed raw material powder. Put the mixed raw material powder in a corundum crucible, place the powder in a muffle furnace after v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap