Micro-channel reactor and preparation method of high-content dichlorvos

A micro-channel reactor, dichlorvos technology, applied in the field of preparation of dichlorvos, can solve the problem of many side reactions in the microreactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

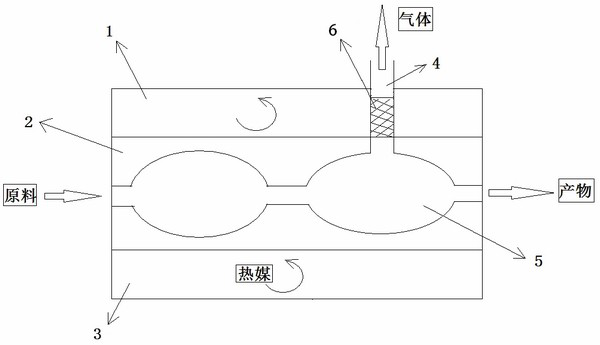

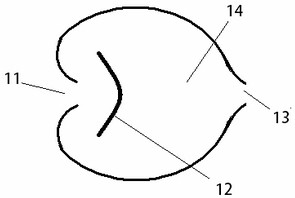

[0033] Such as figure 1 The microchannel reactor shown is a three-layer sandwich structure, with flowing heating medium in the upper and lower layers, and the middle layer is a multi-stage series heart-shaped reaction space; the upper part is reserved for the suction of the middle reaction space. Vacuum holes, holes covered with molecular sieves.

[0034] 1, the trimethyl phosphite (99.6%) of gross weight 252 grams and the chloral (99.7%) of 300 grams, through balance metering, adjust the feed rate 75.6g / min of trimethyl phosphite, three The feed rate of chloroacetaldehyde is 90.0g / min, and the temperature of the reaction module is set at 50°C. After passing through 3 reaction modules, the gas-liquid separation is carried out in the four-necked flask, and the methyl chloride gas is cooled to the vacuum system and then the methyl chloride is removed. In the recovery device, the temperature in the four-necked flask was maintained at 70°C, the vacuum degree was -0.08 Mpa, the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com