Test method and test system for determining active remanufacturing time of roller

A test method and test system technology, which is applied in the field of test systems for determining the timing of active remanufacturing of rolls, can solve problems such as the difficulty in accurately simulating the evolution process of roll coupling damage and the inability to determine the timing of active remanufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

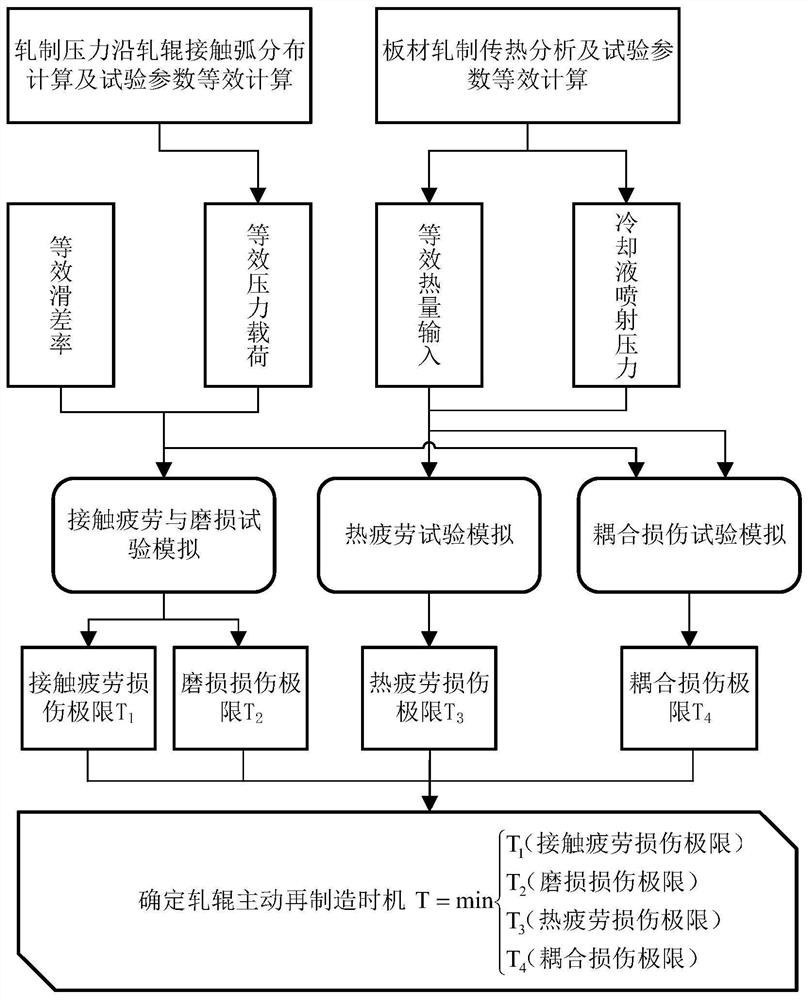

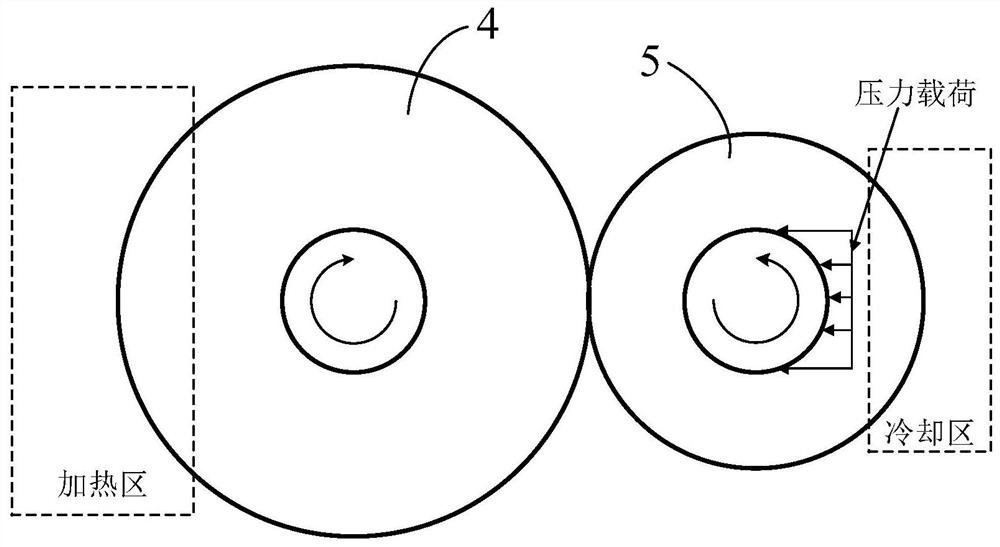

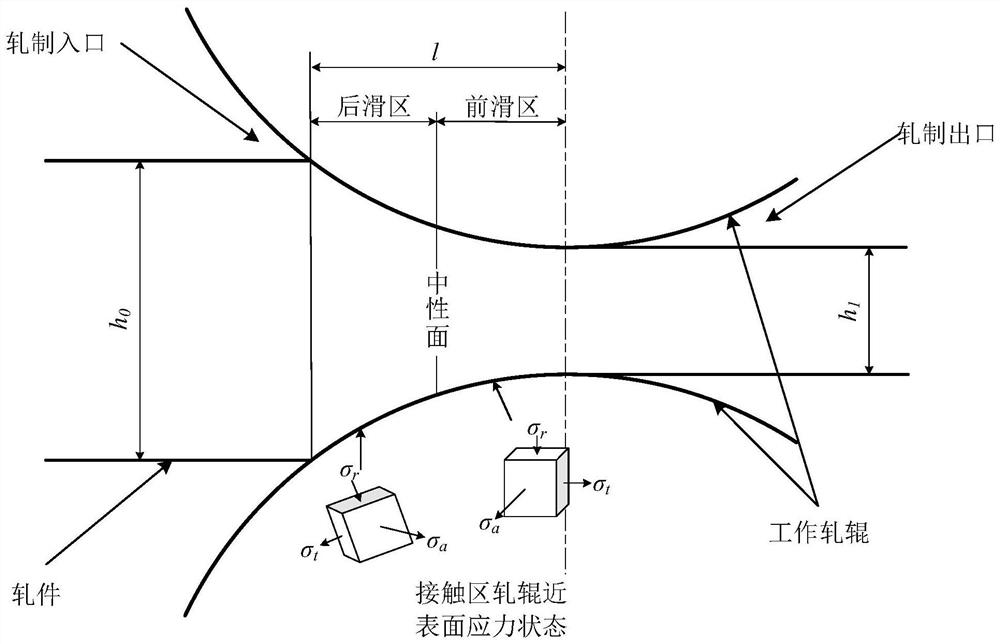

[0093] see Figure 1-4 , this embodiment provides a test method for determining the timing of roll active remanufacturing, the method is used to test the loading roll 4 and the test piece 5 arranged in parallel to the central axis. In this embodiment, through theoretical calculation, on-site data collection, test measurement and finite element simulation, the equivalent loads such as contact load, thermal load and friction force on the rolls in the strip rolling production are applied to the equivalent load through the test bench. The test simulation is carried out on the specimen to realize the simulation of roll wear damage, contact fatigue damage, thermal fatigue damage and the coupling damage of the three. Among them, the loading roll 4 and the test piece 5 are cylindrical, and the test object of this test method is a pair of rolls. The device heats the loading roll 4 in the heating zone. The heating temperature is the same as that of the plate in rolling production. The l...

Embodiment 2

[0111] This embodiment provides a test method for determining the timing of active remanufacturing of rolls. The method is specifically exemplified on the basis of Embodiment 1. Please refer to Table 1 for specific parameters.

[0112] Table 1 Rolling parameter table in production

[0113]

[0114] In step 2, according to the Hertz formula and fatigue damage theory, when the loading roller 4 has a diameter of 60mm and a width of 15mm, and the specimen 5 has a diameter of 30mm and a width of 20mm, when the pressure load is loaded to 6000N, the loading roller 4 and the specimen The maximum contact pressure between 5 is about 1000MPa, so an equivalent pressure of 6000N needs to be applied.

[0115] In step three, according to the contact arc length between the rolling piece and the roll during the roll rolling process, determine the rotational speed difference required to simulate the real wear and damage of the paired rolls, generally in the range of 0.2%-0.5%.

[0116] In s...

Embodiment 3

[0120] This embodiment provides a test method for determining the timing of active remanufacturing of rolls, which is similar to the method in Example 1, the difference is that the calculation formulas for the timing of active remanufacturing of rolls are different, and multiple calculations are provided in this embodiment formula.

[0121] One of the formulas for calculating the timing of active remanufacturing of rolls is:

[0122]

[0123] In the formula, α, β, χ, δ are the determination coefficients of contact fatigue damage limit, wear damage limit, thermal fatigue damage limit and coupling damage limit respectively, which are determined according to actual needs.

[0124] Another formula for calculating the timing of active remanufacturing of rolls is:

[0125]

[0126] In the formula, T 0 It is the initial value of remanufacturing timing.

[0127] Another formula for calculating the timing of active remanufacturing of rolls is:

[0128]

[0129] In the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com