Preparation method of T-type molecular sieve/BTESE composite membrane

A molecular sieve and composite membrane technology, applied in the field of composite membranes, can solve the problems of low repeatability of preparation and affecting the commercial application of T-type molecular sieve membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

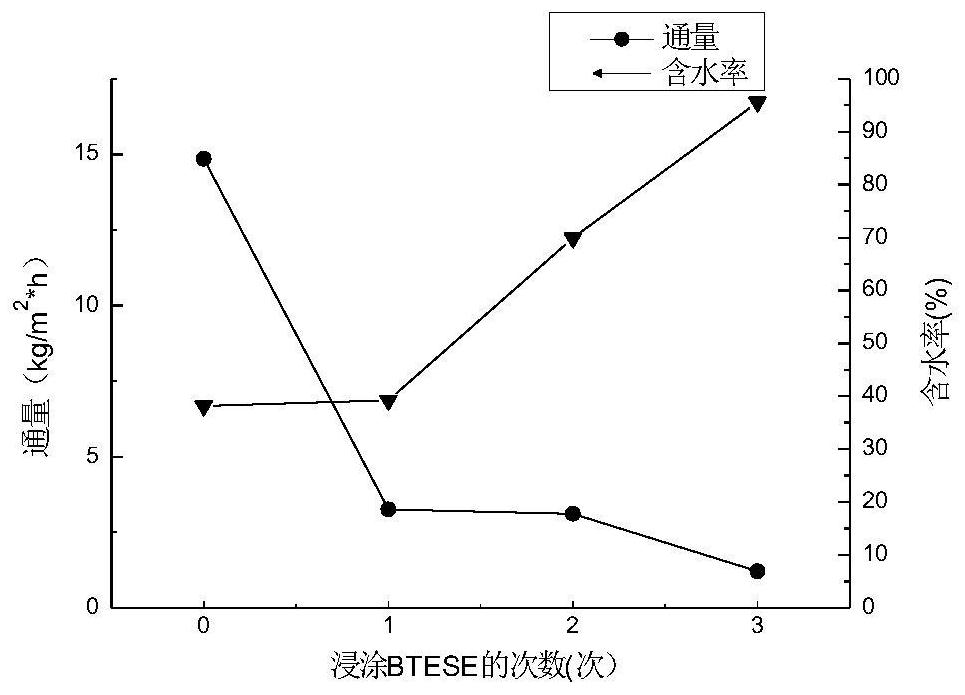

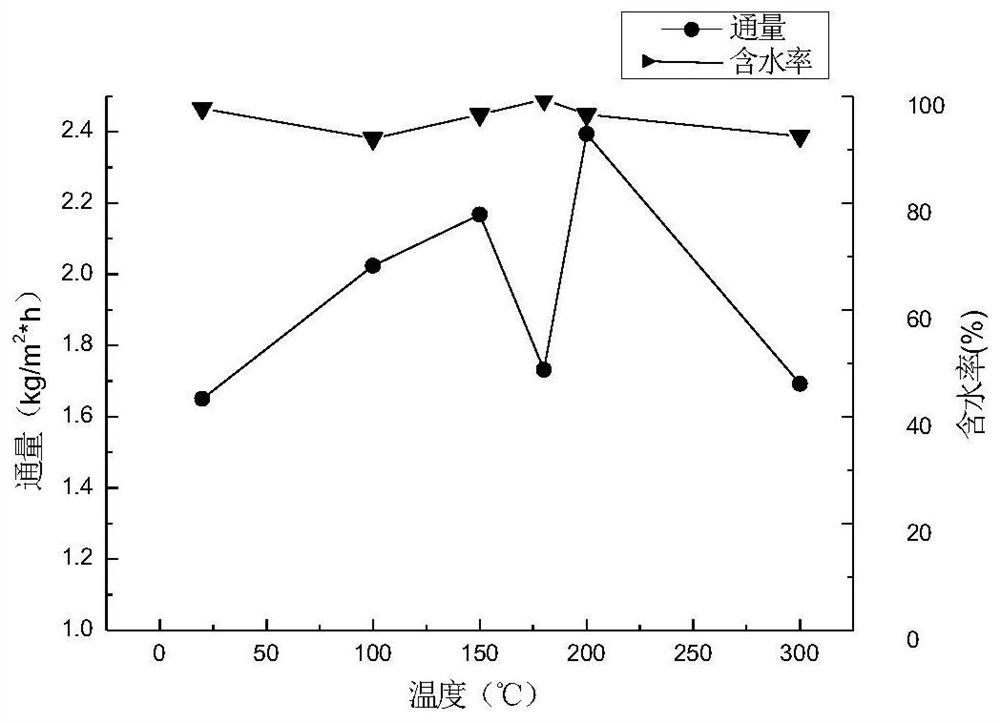

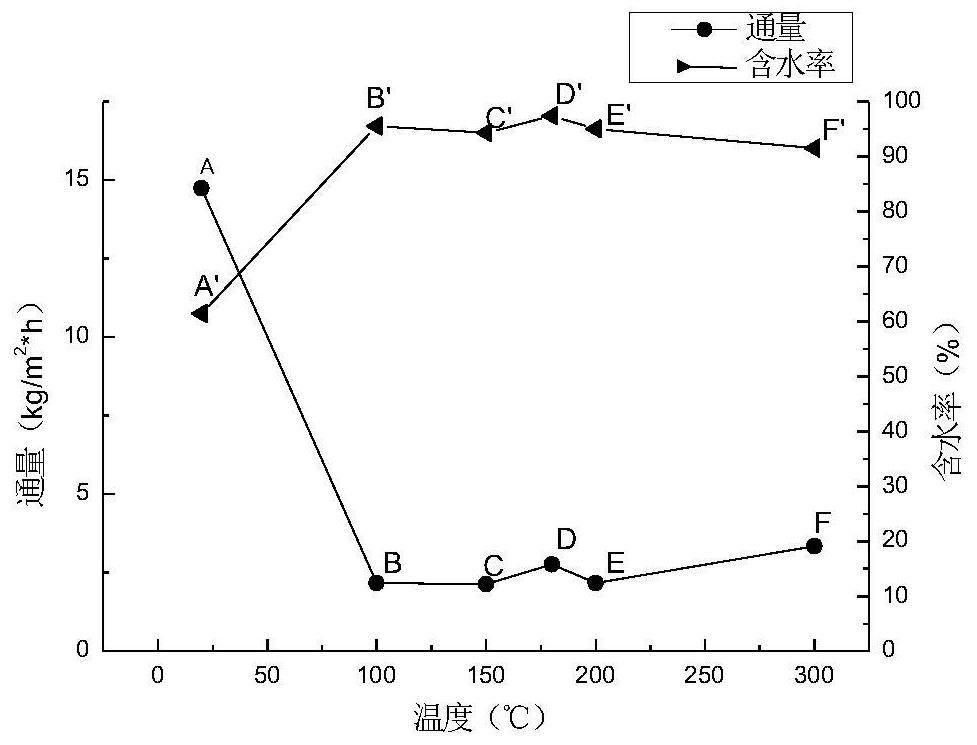

Method used

Image

Examples

Embodiment 1

[0033] (1) Select high-quality α-Al with a length of 250mm, an outer diameter of 12mm, an average pore diameter of 2-3μm, and a porosity of 30-40%. 2 o 3 Carrier tube, put it into an ultrasonic cleaner for cleaning to obtain a clean and smooth carrier tube; seal both ends of the carrier tube with polytetrafluoroethylene plugs, and bake at 175°C for 3-4h;

[0034](2) The first hot dipping: Take 6g of industrial T molecular sieve coarse seeds with an average particle size of 1.6 μm and a silicon-aluminum molar ratio of 25 (purchased from Langfang Naco New Material Technology Co., Ltd.) and dissolve them in 500 mL of deionized water , sonicated for 1h to prepare a coarse seed solution; take out the carrier tube treated at 175°C, immerse in the coarse seed solution for 40s, remove the polytetrafluoroethylene plug at the mouth of the carrier tube, release the water immersed in the carrier tube, and put it at 75°C drying;

[0035] (3) Seal both ends of the carrier tube pre-coated ...

Embodiment 2

[0048] In this example, on the basis of Example 1, the content of hydrochloric acid in the BTESE solution is reduced, and a composite membrane of T-type molecular sieve and BTESE is prepared, and other raw materials and synthesis conditions are the same as in Example 1. The BTESE solution of described low hydrochloric acid content is prepared by following method: by following molar ratio BTESE:EtOH:H 2 O:HCl=1:28:300:0.05 Add BTESE to the mixture of ethanol and water, finally add a small amount of hydrochloric acid, add three times the volume of deionized water after stirring for two hours, and stir for three hours to obtain the BTESE solution, and then carry out The same follow-up operation as in Example 1, and performance evaluation of the finally synthesized BTESE / T composite membrane, the separation factor was as high as 12000.

Embodiment 3

[0050] This example uses the same synthetic raw materials, synthetic conditions and synthetic methods as in Example 1. After synthesizing a T-type molecular sieve and BTESE composite membrane, it is placed in a nitric acid solution with a pH of (5 ± 0.2) for 7 days, and then it is taken out and dried. A pervaporation experiment was carried out to test the separation performance of the composite membrane, and the separation factor was as high as 10,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com