Photocatalyst and application thereof in photocatalytic environment-friendly treatment of power battery

A photocatalyst and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical/physical process, etc. It can solve the problems of low degradation rate, inability to effectively recycle the diaphragm, and inability to treat the electrolyte alone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

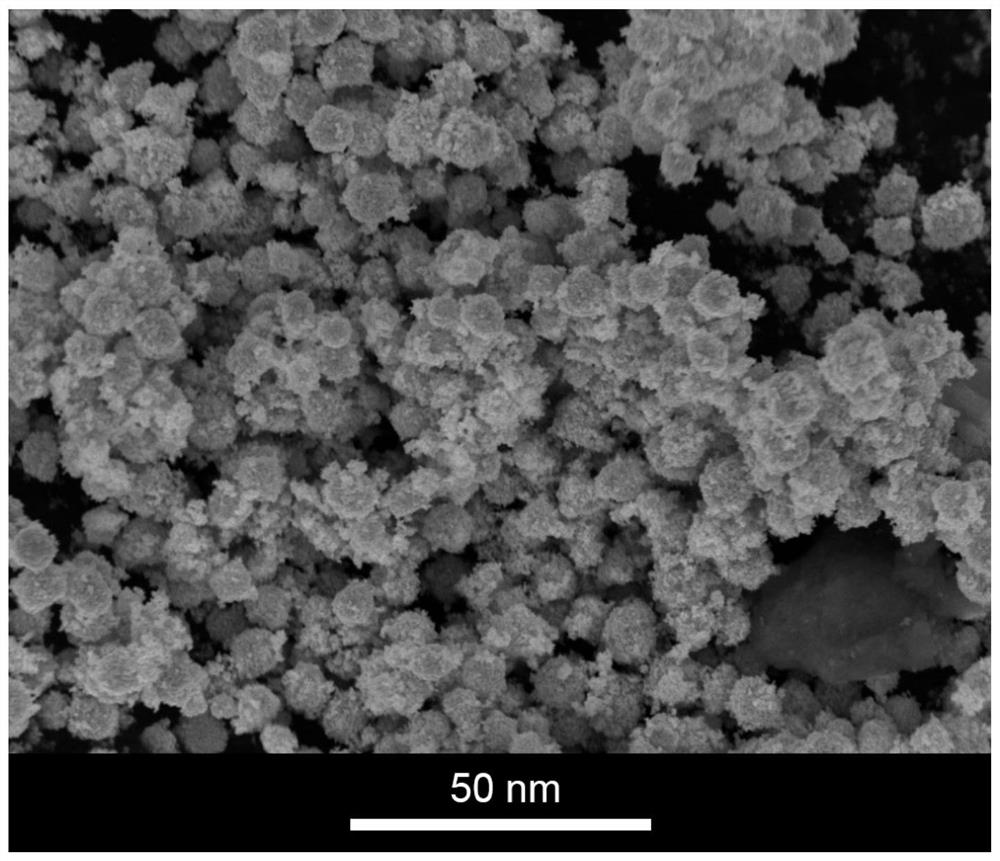

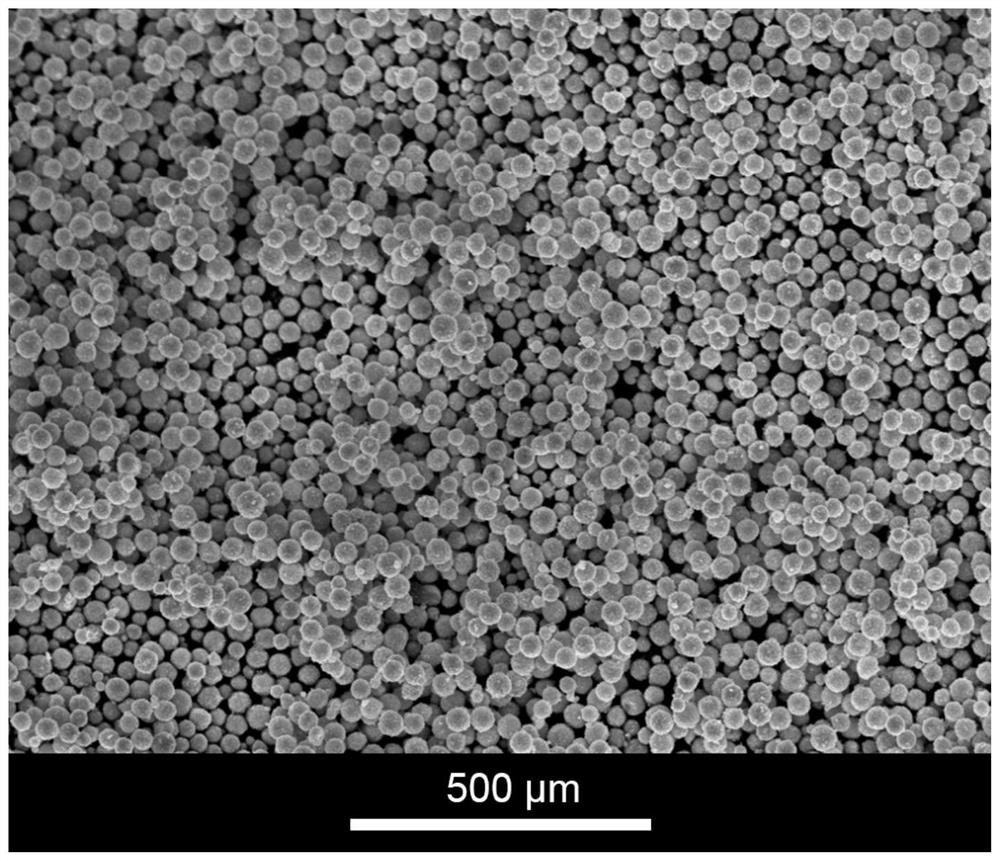

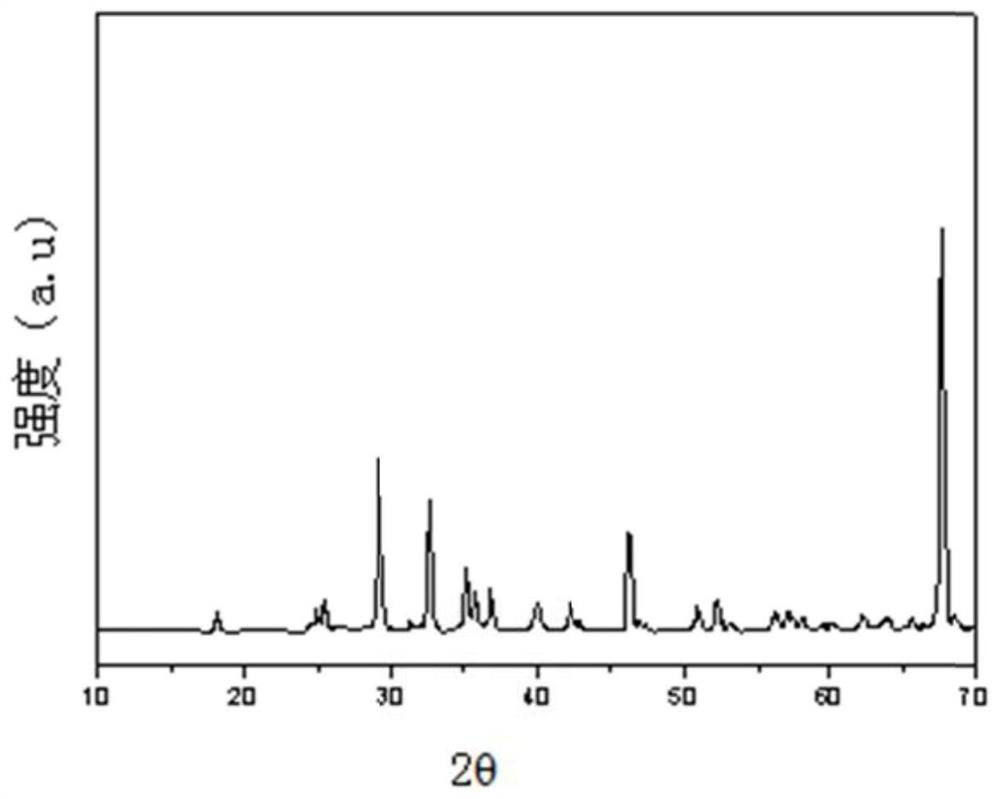

[0056] A photocatalyst is obtained by loading Ag-TaON on hollow glass microspheres; the mass ratio of Ag-TaON to hollow glass microspheres is 1:5.

[0057] A preparation method of a power battery photocatalyst, comprising the following steps:

[0058] (1) Push the corundum porcelain boat filled with tantalum foil into the middle heating section of the tube furnace, seal it with a flange, and flow at a flow rate of 2mL min at ambient temperature -1 Pure N 2 20min, then switch the gas path to flow rate 2mL min -1 Access to H 2 and N 2 mixture, H 2 The concentration is 5%, and at the same time, the temperature control program is turned on at 2°C·min -1 Raise the temperature to 250°C at a certain rate and keep it warm for 30 minutes;

[0059] (2) Lower the temperature to the ambient temperature, switch the gas path to a flow rate of 2mL min -1 Pure N 2 20min, then switch the gas path to flow rate 2mL min -1 Access O 2 and N 2 mixture, O 2 The concentration is 5%, and...

Embodiment 2

[0067] A photocatalyst is obtained by loading Ag-TaON on hollow glass microspheres; the mass ratio of Ag-TaON and hollow glass microspheres is 1:8.

[0068] A method for preparing a photocatalyst, comprising the steps of:

[0069] (1) Push the corundum porcelain boat filled with tantalum foil into the middle heating section of the tube furnace, seal it with a flange, and flow at a flow rate of 15mL min at ambient temperature -1 Inject pure Ar for 70 minutes, then switch the gas path to a flow rate of 15mL min -1 Access to H 2 and N 2 mixture, H 2 The concentration is 8%, and at the same time, the temperature control program is turned on at 5°C·min -1 Raise the temperature to 300°C at a certain rate and keep it warm for 90 minutes;

[0070] (2) Reduce the temperature to the ambient temperature, switch the gas path to a flow rate of 15mL min -1 And feed pure Ar within 70min, and then switch the gas circuit with a flow rate of 15mL min -1 Access O 2 and N 2 mixture, O 2...

Embodiment 3

[0078] A photocatalyst is obtained by loading Ag-TaON on hollow glass microspheres; the mass ratio of Ag-TaON and hollow glass microspheres is 1:8.

[0079] A method for preparing a photocatalyst, comprising the steps of:

[0080] (1) Push the corundum porcelain boat filled with tantalum foil into the middle heating section of the tube furnace, seal it with a flange, and flow at a flow rate of 15mL min at ambient temperature -1 Inject pure Ar for 70 minutes, then switch the gas path to a flow rate of 15mL min -1 Access to H 2 and N 2 mixture, H 2 The concentration is 8%, and at the same time, the temperature control program is turned on at 5°C·min -1 Raise the temperature to 300°C at a certain rate and keep it warm for 90 minutes;

[0081] (2) Reduce the temperature to the ambient temperature, switch the gas path to a flow rate of 15mL min -1 And feed pure Ar within 70min, and then switch the gas circuit with a flow rate of 15mL min -1 Access O 2 and N 2 mixture, O 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com