Oxygen-limited microbial desalting tank and wastewater treatment method

A technology for wastewater treatment and microorganisms, which is applied in biological water/sewage treatment, electrochemical biological combined treatment, water treatment parameter control, etc., and can solve problems such as inability to effectively remove total nitrogen from wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Oxygen-limited microbial desalination tank structure

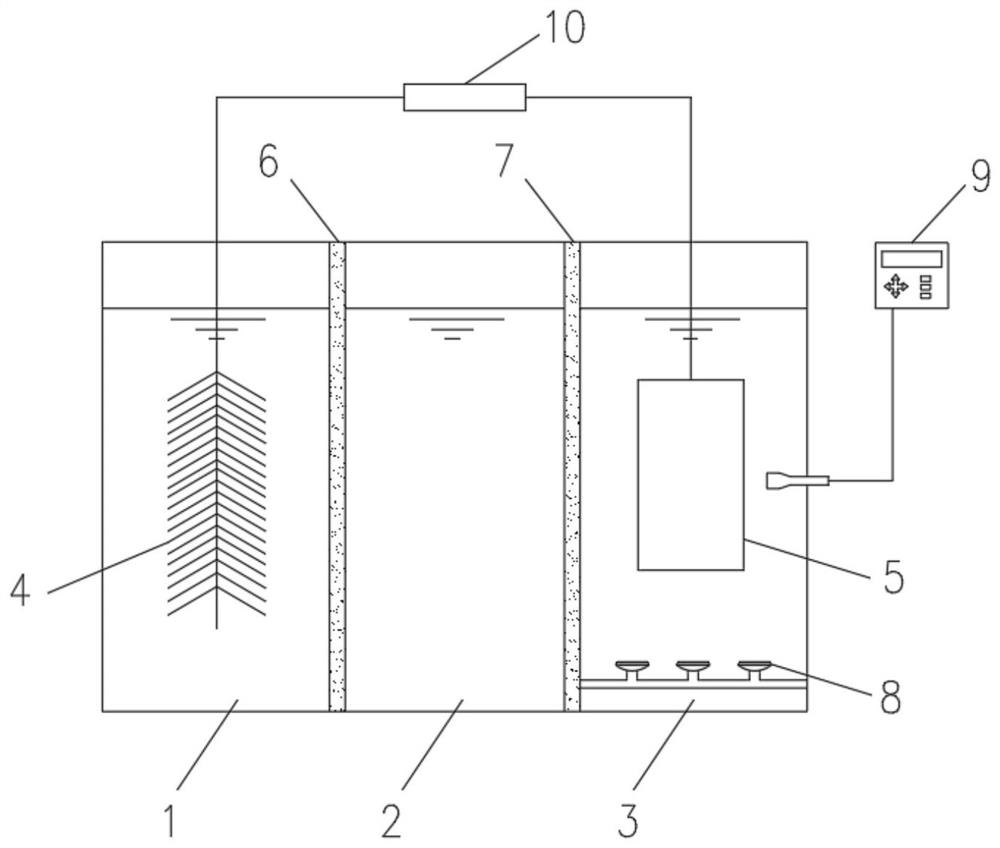

[0022] Such as figure 1 As shown, the oxygen-limited microbial desalination tank includes an anode chamber 1, a desalination chamber 2, a cathode chamber 3, an anode electrode 4, a cathode electrode 5, an anion exchange membrane 6, a cation exchange membrane 7, an aeration device 8, and a dissolved oxygen detector 9. And external circuit 10.

[0023] The oxygen-restricted microbial desalination tank of the present invention is divided into three chambers, the middle chamber is the desalination chamber 2, the chambers on both sides are the anode chamber 1 and the cathode chamber 2, and the anode chamber 1 and the desalination chamber 2 are composed of an anion exchange membrane 6. The cathode chamber 3 and the desalination chamber 3 are separated by a cation exchange membrane 7. The anode chamber 1 is provided with an anode electrode 4. In this embodiment, the anode electrode 4 is a carbon brush, and the cathod...

Embodiment 2

[0026] Example 2: Method for denitrifying and desalinating wastewater by using the oxygen-limited microbial desalination pond of Example 1

[0027] Source of wastewater: Landfill leachate from a landfill in Beijing, COD 3460mg / L, BOD 1799mg / L, BOD / COD=0.52.

[0028] Sources of anaerobic sludge and sludge containing ammonia oxidizing bacteria: the anaerobic sludge in the present invention can be selected from the sludge in the sewage anaerobic treatment unit of any sewage treatment plant or the sludge in the sludge anaerobic digestion reaction device , The sludge containing ammonia oxidizing bacteria can be selected from the sludge in the aerobic treatment unit of any sewage treatment plant. The two types of sludge in this example were from the sludge anaerobic digestion reactor and aerobic tank of a municipal sewage treatment plant in Wuxi City, Jiangsu Province, and the sludge concentrations were 77.0 g / L and 3.2 g / L, respectively.

[0029] The source of the sludge containing anamm...

Embodiment 3

[0034] Example 3: Method for denitrifying and desalinating wastewater by using the oxygen-limited microbial desalination tank of Example 1 Wastewater source: the same as Example 2.

[0035] Sources of anaerobic sludge and sludge containing ammonia oxidizing bacteria: the same as in Example 2.

[0036] Source of sludge containing anammox bacteria: the same as in Example 2.

[0037] Step 1: Add 200 mL of landfill leachate to anode compartment 1 as anode feed water; add 10.0 g / L sodium chloride solution 200 mL to desalination compartment 2 as desalination compartment feed water; add waste treated by anode compartment 1 to cathode compartment 3 The supernatant of the leachate (at the first start-up, 200 mL of landfill leachate that has not been treated in the anode compartment 1 is directly added to the cathode compartment 3) as the cathode feed water.

[0038] Step 2: Inoculate 1.5mL of anaerobic sludge with a anaerobic sludge concentration of 77.0g / L in anode compartment 1, and inoculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com