A reaction device and method for producing pha by mainstream recycling of organic matter in beer wastewater

A technology for brewing wastewater and organic matter, applied in chemical instruments and methods, food industry wastewater treatment, water aeration, etc., can solve problems such as effective recovery of unwatered resources, and achieve the effect of promoting wide application, reducing emissions, and alleviating the greenhouse effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

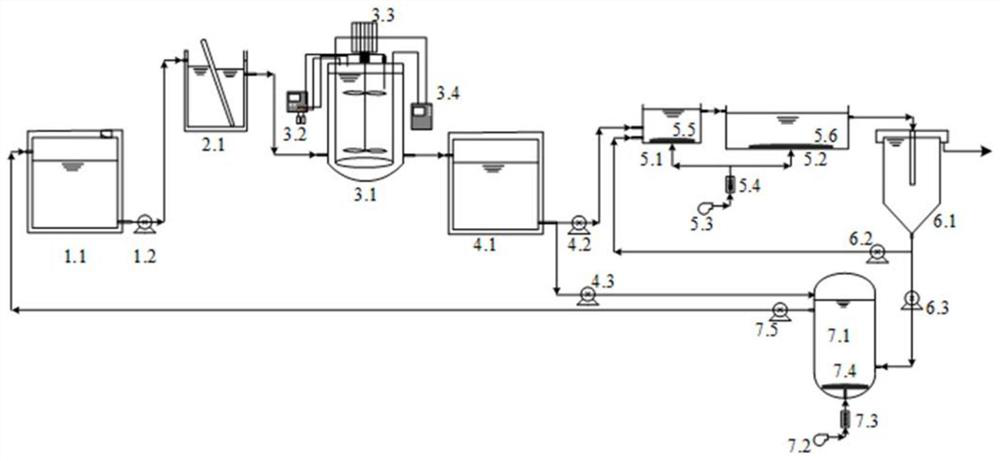

[0028] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited to the following examples.

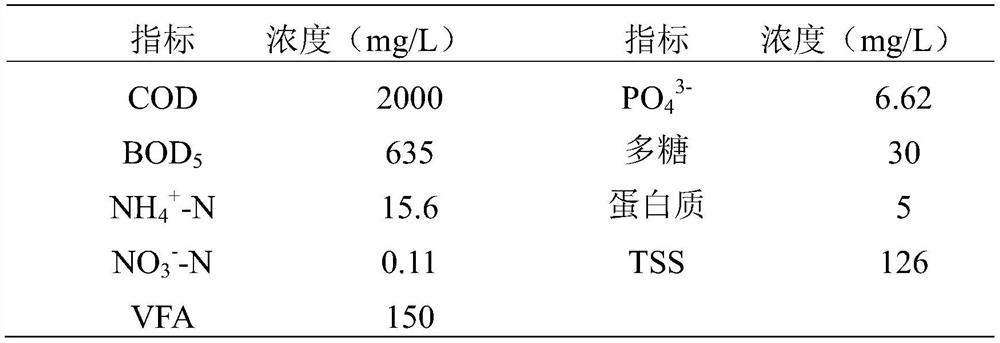

[0029] In this example, wastewater from a brewery in Beijing was used as the research object, and the water quality characteristics are shown in Table 1.

[0030] Table 1 Composition and main properties of brewery wastewater

[0031]

[0032] Carry out according to the process step method in the summary of the invention.

[0033] The effective volume of the first aeration tank is 8L, the effective volume of the second aeration tank is 27L, the influent flow rate is 1.65L / h, the controlled aeration rate is 120L / h, the daily residual sludge volume is 17.5L, and the sludge age is 2d. When the system runs stably, the maximum PHA accumulation capacity of the sludge is 58.77%, and the daily output of PHA is 64.57g / d. The COD effluent concentration is 60-100mg / L, and the removal rate is 94....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com