Bio-based heat-resistant flame-retardant polyester, polyester product, preparation method and application thereof

A flame-retardant polyester and bio-based technology, applied in the field of polymers, can solve problems such as insufficient heat resistance and unsatisfactory flame-retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In some embodiments, the preparation method includes: reacting the first mixed reaction system at 160-260°C for 1-10 hours to obtain an intermediate product.

[0050] In some embodiments, the preparation method includes: making the first mixed reaction system react in a vacuum environment at 200-300°C for 1-10 hours to obtain a bio-based heat-resistant and flame-retardant polyester, and the vacuum of the vacuum environment The degree is below 300Pa.

[0051] In some embodiments, the preparation method specifically includes: reacting the first dibasic alcohol, dibasic acid or its esterified product, the second dibasic alcohol and an esterification or transesterification catalyst at 160-260°C for 1-10 hours, and then Adding a polycondensation catalyst and a stabilizer, reacting for 1-10 hours in an environment with a temperature of 200-300° C. and a vacuum degree below 300 Pa, to obtain a bio-based heat-resistant and flame-retardant polyester.

[0052] In some embodiment...

Embodiment 1

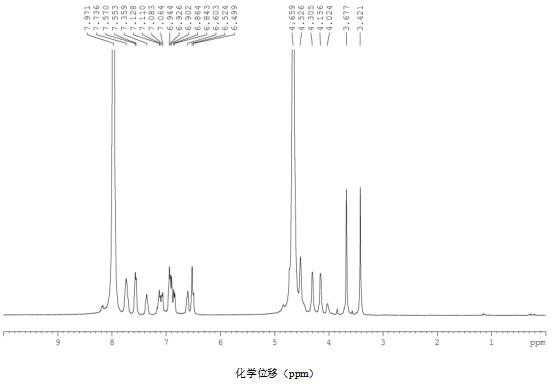

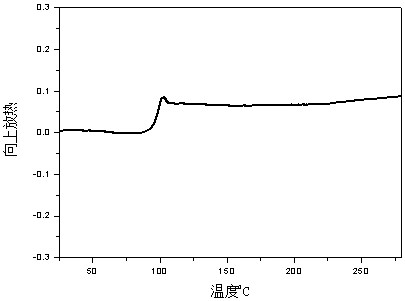

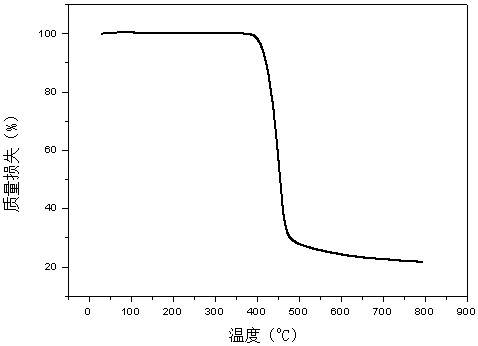

[0094] Example 1 Add terephthalic acid, phosphorus-containing aromatic dihydric alcohol, and ethylene glycol into the reactor in a molar ratio of 1:0.15:2.1, then add anhydrous manganese acetate with a molar mass of terephthalic acid of 0.8‰, and heat up To 240°C, react for 5.0h, then add antimony trioxide with a molar mass of terephthalic acid of 0.4‰, triphenyl phosphate with a molar mass of terephthalic acid of 0.5‰, vacuum 30Pa, heat up to 280°C, and react for 4.0h , to obtain polyethylene terephthalate phosphorus-containing aromatic diol copolyester, the copolyester structure is shown in formula V, 1 H-NMR such as figure 1 Shown; the glass transition temperature is 97°C, and the DSC spectrum is as follows figure 2 Shown; T in nitrogen 5% The thermal weight loss temperature is 410°C, and the TGA spectrum is as follows image 3 Shown, flame retardant performance test V1 level.

[0095]

[0096] Formula V (m, n is an integer of 1-20; y is an integer of 10-200)

Embodiment 2

[0097] Example 2 Add terephthalic acid, phosphorus-containing aromatic dihydric alcohol, and ethylene glycol into the reactor in a molar ratio of 1:0.06:2.1, then add anhydrous manganese acetate with a terephthalic acid molar mass of 1.0‰, and heat up To 240°C, react for 4.0h, then add antimony trioxide with a molar mass of terephthalic acid of 0.5‰, triphenyl phosphate with a molar mass of terephthalic acid of 0.6‰, vacuum degree 50Pa, heat up to 278°C, and react for 4.0h , to obtain polyethylene terephthalate copolyester containing aromatic diol phosphorus, glass transition temperature 87 ℃, flame retardant performance test level V1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com