Bio-based heat-resistant flame-retardant polyester, polyester products, preparation method and application thereof

A flame retardant polyester, bio-based technology, applied in the polymer field, can solve the problems of unsatisfactory flame retardant performance, insufficient heat resistance, etc., to solve the problems of insufficient heat resistance and flame retardant, excellent rigidity, heat resistance and Excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In some embodiments, the preparation method includes: reacting the first mixed reaction system at 160-260°C for 1-10 hours to obtain an intermediate product.

[0050] In some embodiments, the preparation method includes: making the first mixed reaction system react in a vacuum environment at 200-300°C for 1-10 hours to obtain a bio-based heat-resistant and flame-retardant polyester, and the vacuum of the vacuum environment The degree is below 300Pa.

[0051] In some embodiments, the preparation method specifically includes: reacting the first dibasic alcohol, dibasic acid or its esterified product, the second dibasic alcohol and an esterification or transesterification catalyst at 160-260°C for 1-10 hours, and then Adding a polycondensation catalyst and a stabilizer, reacting for 1-10 hours in an environment with a temperature of 200-300° C. and a vacuum degree below 300 Pa, to obtain a bio-based heat-resistant and flame-retardant polyester.

[0052] In some embodiment...

Embodiment 1

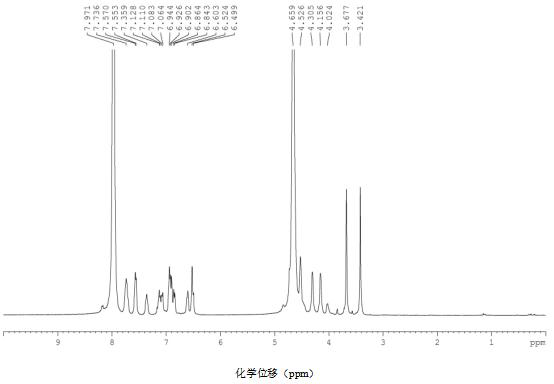

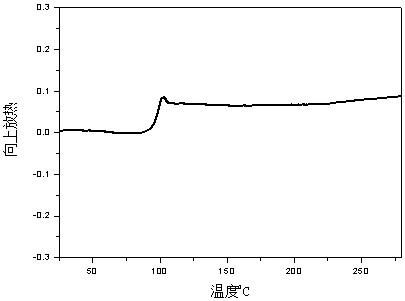

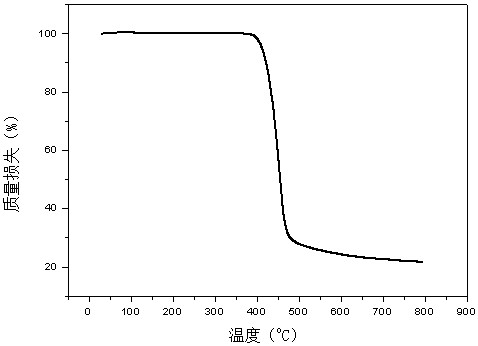

[0094] Example 1 Add terephthalic acid, phosphorus-containing aromatic dihydric alcohol, and ethylene glycol into the reactor in a molar ratio of 1:0.15:2.1, then add anhydrous manganese acetate with a molar mass of terephthalic acid of 0.8‰, and heat up To 240°C, react for 5.0h, then add antimony trioxide with a molar mass of terephthalic acid of 0.4‰, triphenyl phosphate with a molar mass of terephthalic acid of 0.5‰, vacuum 30Pa, heat up to 280°C, and react for 4.0h , to obtain polyethylene terephthalate phosphorus-containing aromatic diol copolyester, the copolyester structure is shown in formula V, 1 H-NMR such as figure 1 Shown; the glass transition temperature is 97°C, and the DSC spectrum is as follows figure 2 Shown; T in nitrogen 5% The thermal weight loss temperature is 410°C, and the TGA spectrum is as follows image 3 Shown, flame retardant performance test V1 level.

[0095]

[0096] Formula V (m, n is an integer of 1-20; y is an integer of 10-200)

Embodiment 2

[0097] Example 2 Add terephthalic acid, phosphorus-containing aromatic dihydric alcohol, and ethylene glycol into the reactor in a molar ratio of 1:0.06:2.1, then add anhydrous manganese acetate with a terephthalic acid molar mass of 1.0‰, and heat up To 240°C, react for 4.0h, then add antimony trioxide with a molar mass of terephthalic acid of 0.5‰, triphenyl phosphate with a molar mass of terephthalic acid of 0.6‰, vacuum degree 50Pa, heat up to 278°C, and react for 4.0h , to obtain polyethylene terephthalate copolyester containing aromatic diol phosphorus, glass transition temperature 87 ℃, flame retardant performance test level V1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com