Method for sticking out dirt during germanium crystal growth

A crystal growth and crystal technology, which is applied in the field of semiconductor preparation, can solve the problems of prolonging the crystal growth cycle, loss of raw materials and costs, and heavy weight of dirty materials, and achieve the effects of reduced loss, small weight, and tight scum arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. After the calcination of the germanium material is completed, the temperature is slowly lowered to the vicinity of the seeding temperature, and the crucible is rotated 1r / min, and the crystal is rotated 1r / min, and the seed crystal is slowly lowered to 10mm above the liquid surface of the melt, and baked for 15min;

[0030] 2. Lower the seed crystal to contact with the melt and continue to lower it by 2mm. After the welding is stable, set a slow pulling speed of 0.1mm / min to start seeding;

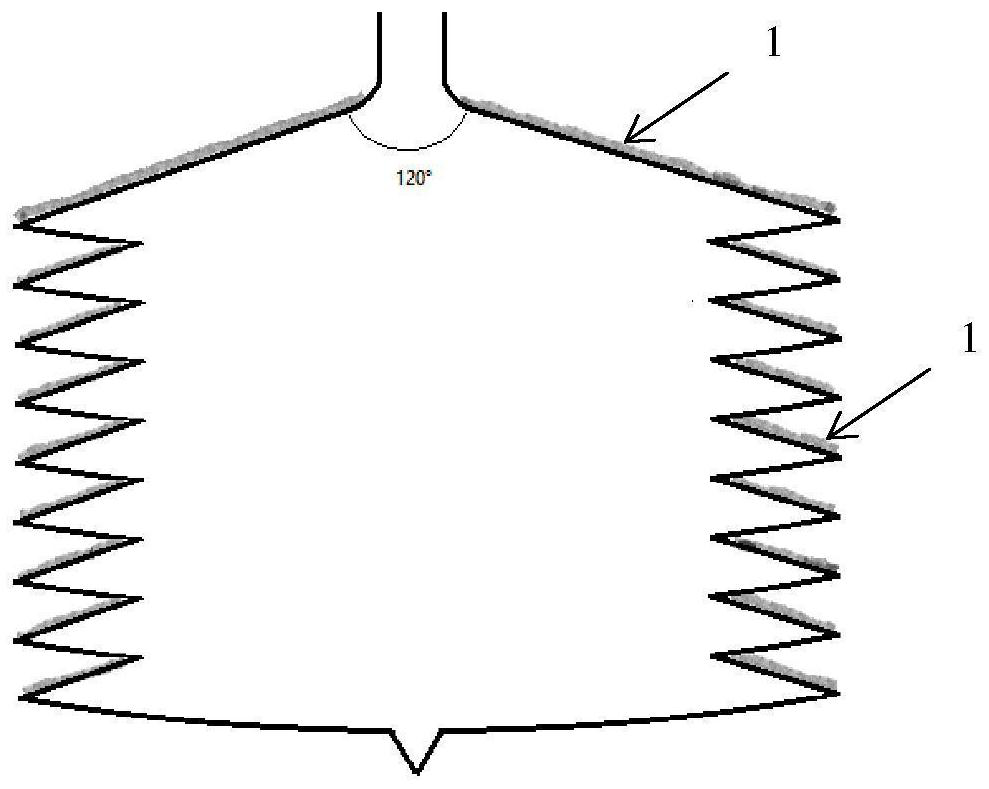

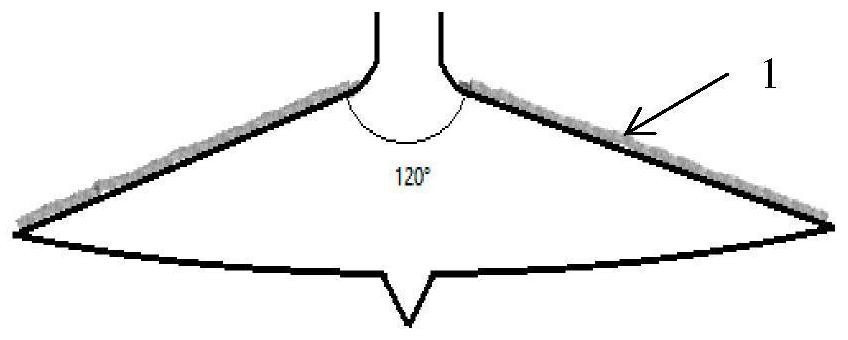

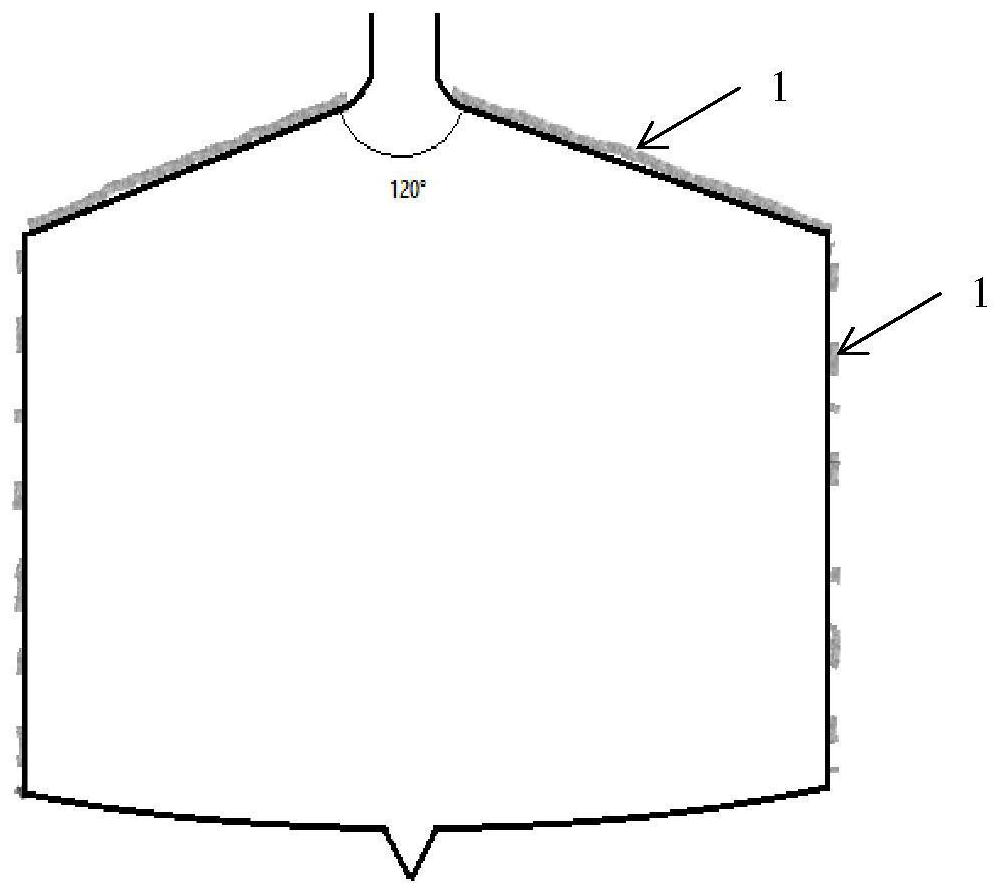

[0031] 3. The seeding length is 4mm, and the power is reduced to shoulder, so that the shoulder angle is about 120°;

[0032] 4. When the diameter of the crystal grows close to the opening diameter of the upper heat preservation channel, switch the automatic slow pulling speed to the manual fast pulling speed. The preset fast pulling speed is 1mm / s, and control the edge of the dirty material from the melt liquid by jogging The surface is 3mm, the central area of the dirty mater...

Embodiment 2

[0036] 1. After the calcination of the germanium material is completed, the temperature is slowly lowered to the vicinity of the seeding temperature, and the crucible is rotated 1r / min, the crystal is rotated 1r / min, the seed crystal is slowly lowered to 10mm above the melt liquid level, and baked for 20min;

[0037] 2. Lower the seed crystal to contact with the melt and continue to lower it by 3mm. After the welding is stable, set a slow pulling speed of 0.1mm / min to start seeding;

[0038] 3. The length of the seeding is 5mm. After the seeding is completed, the power is reduced and the shouldering is started, so that the shouldering angle is about 150°;

[0039] 4. When the diameter of the crystal grows close to the opening diameter of the upper heat preservation channel, switch the automatic slow pulling speed to the manual fast pulling speed. The preset fast pulling speed is 1mm / s, and control the edge of the dirty material from the melt liquid by jogging The surface is 2m...

Embodiment 3

[0043] 1. After the calcination of the germanium material is completed, the temperature is slowly lowered to the vicinity of the seeding temperature, and the crucible is rotated at 2r / min, and the crystal is rotated at 2r / min, and the seed crystal is slowly lowered to 15mm above the melt surface, and baked for 10min;

[0044] 2. Lower the seed crystal to contact with the melt and continue to lower it by 2mm. After the welding is stable, set a slow pulling speed of 0.2mm / min to start seeding;

[0045] 3. The length of the seeding is 5mm. After the seeding is completed, the power is reduced and the shouldering is started, so that the shouldering angle is about 150°;

[0046] 4. When the diameter of the crystal grows close to the opening diameter of the upper heat preservation channel, switch the automatic slow pulling speed to the manual fast pulling speed. The preset fast pulling speed is 2mm / s, and control the edge of the dirty material from the melt liquid by jogging The surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com