Neodymium-iron-boron magnet preparation device

A NdFeB system technology, applied in the direction of magnetic objects, inductors/transformers/magnets manufacturing, magnetic materials, etc., can solve the problems of inability to meet large-scale production, low production efficiency, and low product performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

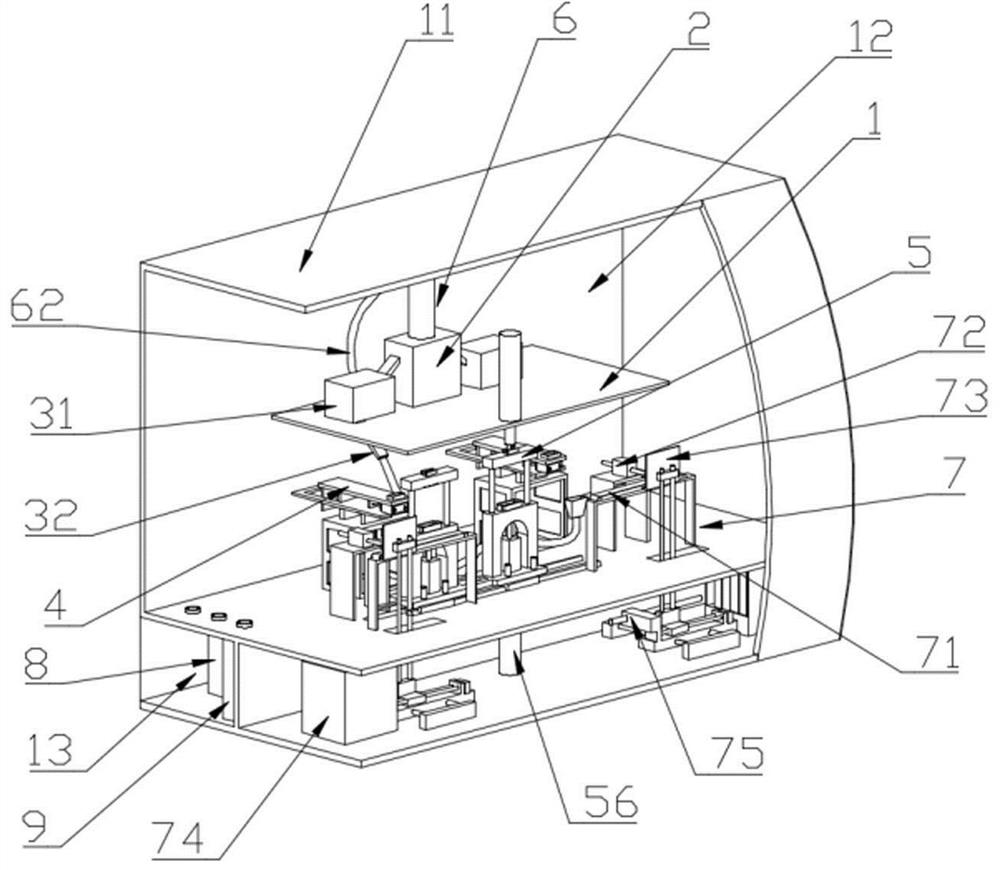

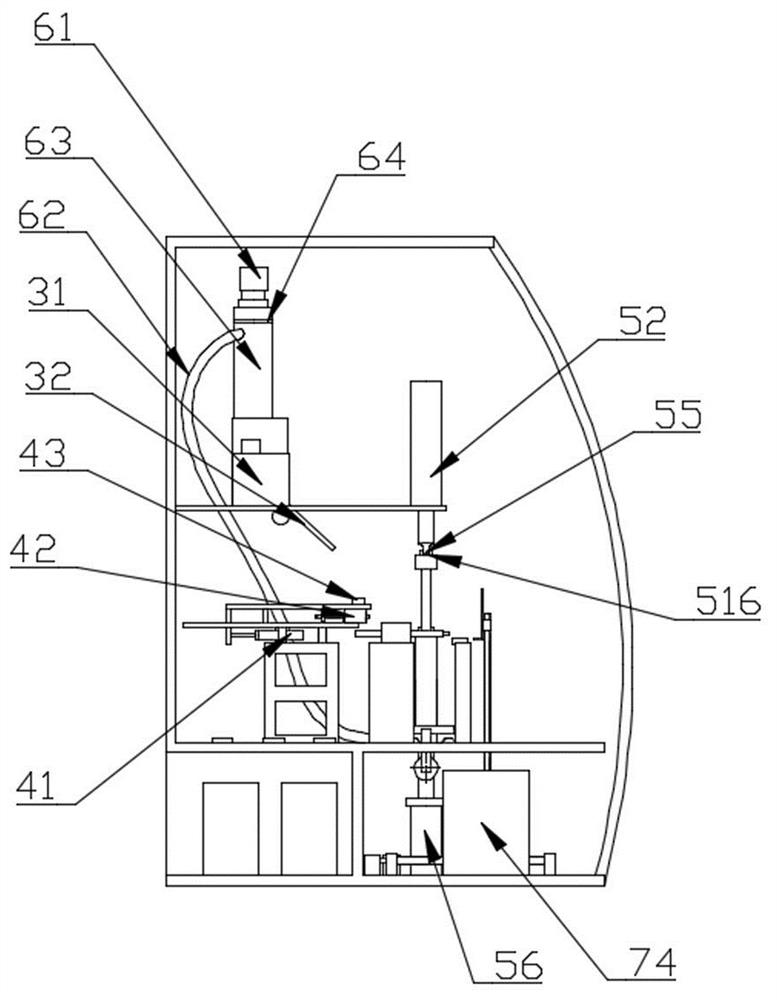

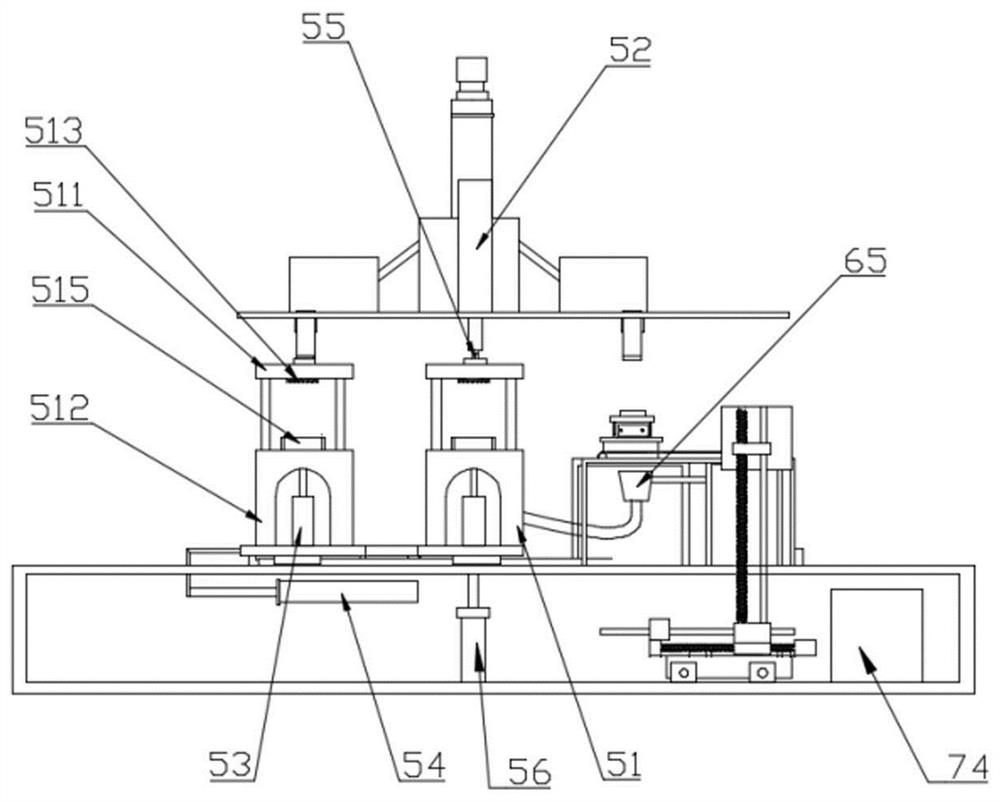

[0048] like Figure 1 to Figure 8 Shown: a NdFeB magnet preparation device, including a frame 1, a silo 2, a distributing device 3, a feeding device 4, a molding device 5, a coding device 6, a powder recovery device 7 and a control system;

[0049] The frame includes a working bin 12 and an auxiliary bin 13. The feed bin 2, the material distributing device 3, the feeding device 3, the molding device 5, the coding device 6, and the powder recovery device 7 are all arranged in the working bin. The control system includes electrical The cabinet 8 and the hydraulic system 9, the electrical cabinet and the hydraulic system are arranged in the auxiliary warehouse 13.

[0050] The silo 2 is set on the upper end of the frame 1, and the silo 2 is provided with an electromagnetic switch to control the powder output, and the electromagnetic switch is connected to the control system;

[0051] Said distributing device 3 comprises a weighing machine 31 and a distributing device 32, the wei...

Embodiment 2

[0073] like Figure 7As shown, the difference between this embodiment and Embodiment 1 is that the structure II in the dispenser also includes a cylinder III 355, and the cylinder III 355 is arranged below the cylinder I 352, and the axis of the cylinder III 355 and the axis of the cylinder I 352 Corresponding to the outer blanking point, the upper ends of the two flat plates II 353 coincide with the projection of the cylinder III 355 in the vertical direction, and the outer blanking of the cylinder I 352 is divided into two by the cylinder III 355 again; the distributor also includes a cylinder IV 356, the cylinder IV 356 is set under the cylinder III 355, the axis of the cylinder IV 356 corresponds to the inner blanking point of the cylinder III 355, and the cylinder IV 356 divides the inner blanking of the cylinder III into two again.

[0074] Operation method:

[0075] 1. The control system controls the electromagnetic switch of bin 2 to open, and bin 2 starts to discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com