Pimavanserin nanocrystalline capsule and preparation method thereof

A technology of pimavanserin and nanocrystals, which is applied in the field of pimavanserin nanocrystal capsules and its preparation, and can solve the problems of poor dissolution rate and low bioavailability of pimavanserin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

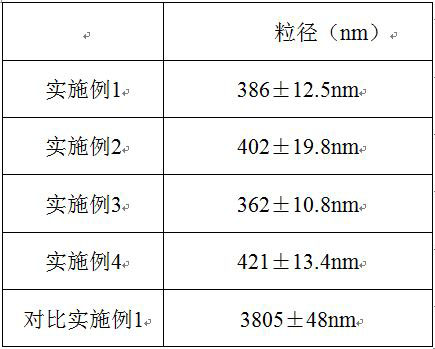

Examples

Embodiment 1

[0019] Take 2g of pimavanserin and 6g of poloxamer 188, add them to 60mL of water, and stir evenly with magnetic force; put the above mixed solution into a high-pressure homogenizer, control the temperature of the preparation process at 35°C, and circulate and homogenize under the pressure of 750Bar 3 times to obtain pimavanserin nanocrystal suspension; take the pimavanserin nanocrystal suspension and place it in a spray dryer for spray drying, and the spray drying inlet temperature is 120°C to obtain pimavanserin Nanocrystalline spray-dried product; pass the pimavanserin nanocrystalline spray-dried product through an 80-mesh sieve, mix it with the prescribed amount of spray-dried lactose, microcrystalline cellulose and magnesium stearate, and fill it into capsules to obtain pimavanserin Vanserin nanocrystalline capsules.

Embodiment 2

[0021] Take 2g of pimavanserin and 12g of poloxamer 188, add it to 200mL of water, and stir evenly with a magnetic force; put the above mixed solution into a high-pressure homogenizer, control the temperature of the preparation process at 35°C, and circulate and homogenize under the pressure of 750Bar 3 times to obtain pimavanserin nanocrystal suspension; take the pimavanserin nanocrystal suspension and place it in a spray dryer for spray drying, and the spray drying inlet temperature is 150°C to obtain pimavanserin Nanocrystalline spray-dried product; pass the pimavanserin nanocrystalline spray-dried product through an 80-mesh sieve, mix it with the prescribed amount of spray-dried lactose, microcrystalline cellulose and magnesium stearate, and fill it into capsules to obtain pimavanserin Vanserin nanocrystalline capsules.

Embodiment 3

[0023] Take 2g of pimavanserin and 8g of poloxamer 188, add it to 100mL of water, and stir evenly with a magnetic force; put the above mixed solution into a high-pressure homogenizer, control the temperature of the preparation process at 35°C, and circulate and homogenize under the pressure of 750Bar 3 times to obtain pimavanserin nanocrystal suspension; take the pimavanserin nanocrystal suspension and place it in a spray dryer for spray drying, and the spray drying inlet temperature is 150°C to obtain pimavanserin Nanocrystalline spray-dried product; pass the pimavanserin nanocrystalline spray-dried product through an 80-mesh sieve, mix it with the prescribed amount of spray-dried lactose, microcrystalline cellulose and magnesium stearate, and fill it into capsules to obtain pimavanserin Vanserin nanocrystalline capsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com