Transmission mechanism of cyclone type milling machine

A technology of transmission mechanism and face milling machine, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., which can solve the problem that the ratio between the speed of milling cutter and the speed of rotating body cannot be adjusted, the surface of the billet has obvious knife marks, and the tool is aggravated. Surface and other problems, to achieve the effect of facilitating processing implementation, broad market application prospects, and reducing milling vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

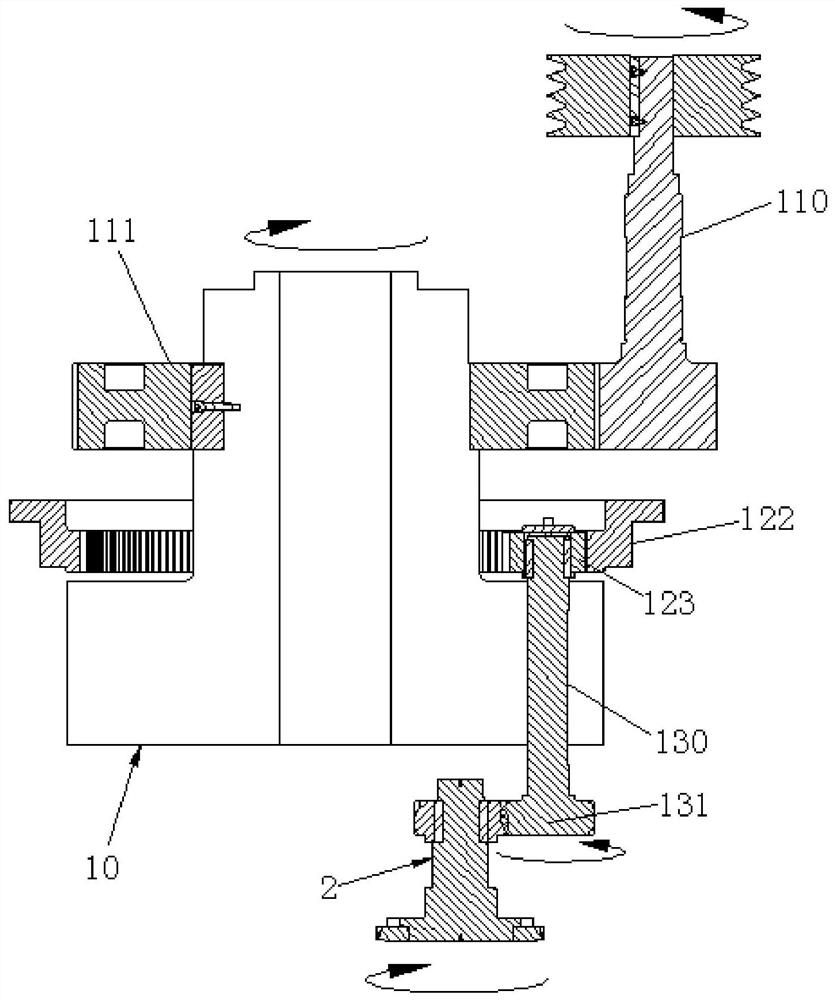

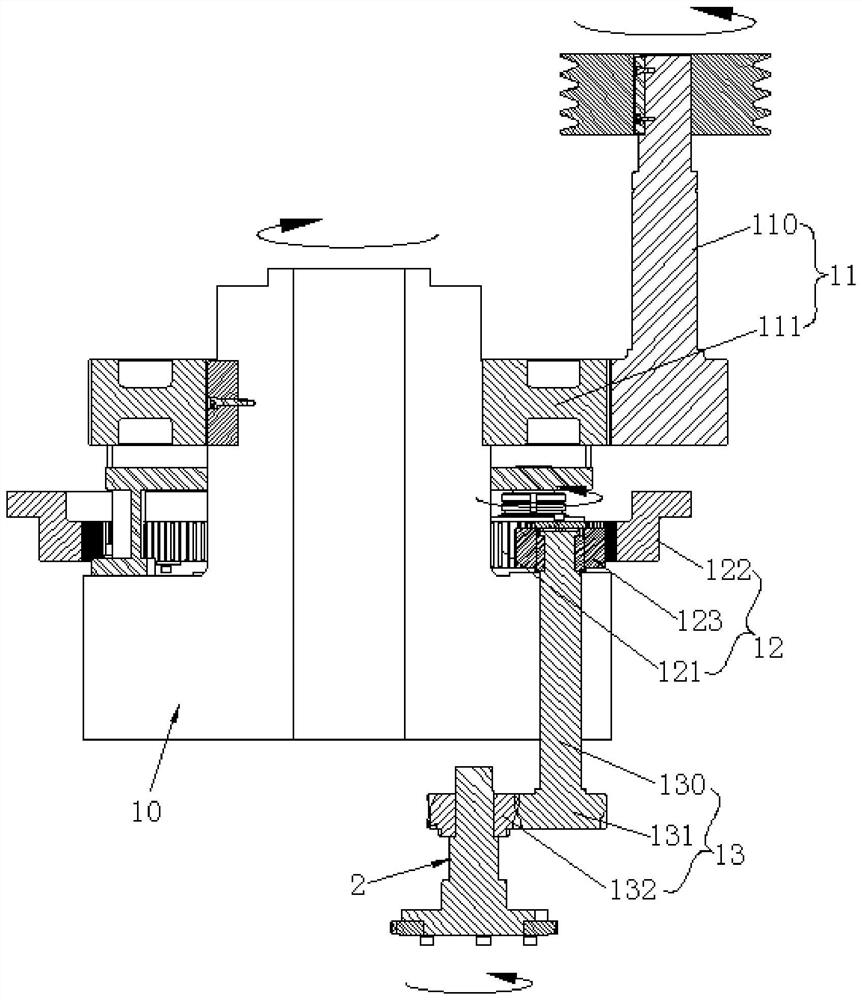

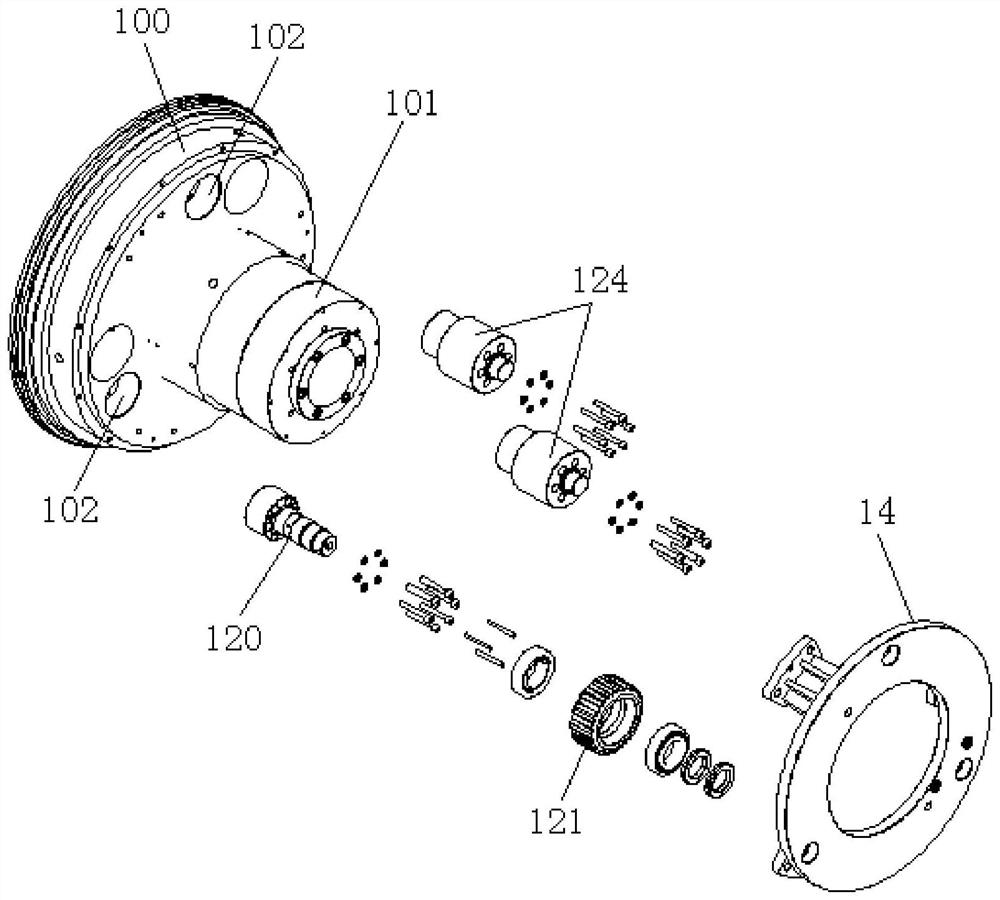

[0028] Please refer to the attached figure 2 And attached image 3 As shown in FIG. 1 and 2 , they are respectively a schematic sectional view and a partial exploded structural view of the transmission mechanism of the whirlwind noodle milling machine of the present invention.

[0029] The transmission mechanism of the cyclone type face milling machine in the present invention includes a rotating body 10, an input transmission assembly 11, an intermediate transmission assembly 12 and an output transmission assembly 13, wherein the rotating body 10 has a base 100 and is integrally formed on the base 100. The connecting shaft portion 101 on the side (the so-called "positive side" and "back side" are only for convenience of description, and are not used to limit the scope of the present invention). The input power transmission assembly 11 has a power supply to the motor The input shaft 110, which is positioned and connected to the output shaft, and a transmission gear A111 whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com