Industrial wastewater advanced treatment system

A technology for advanced treatment of industrial wastewater, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of long treatment cycle, low system efficiency, and ineffective treatment of industrial wastewater Ideal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

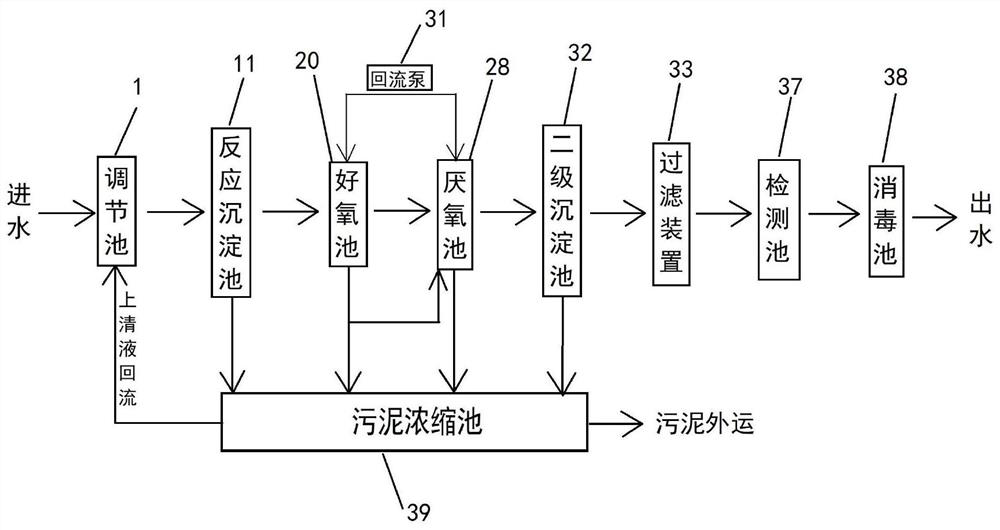

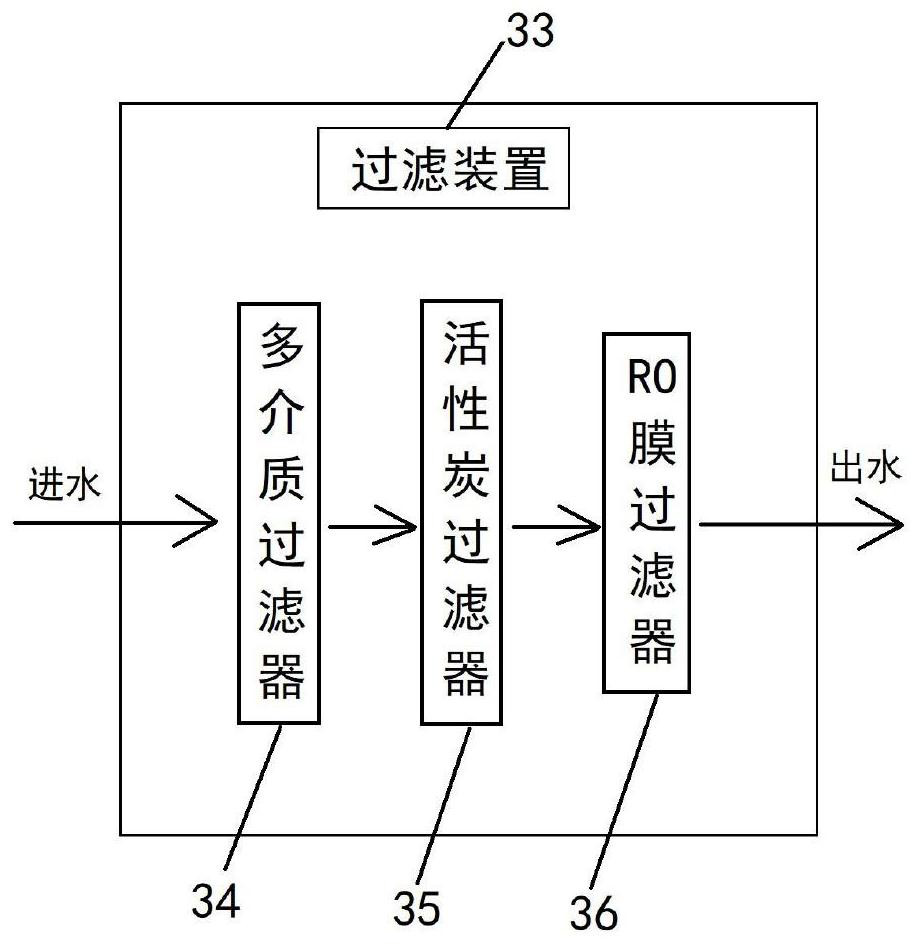

[0020] The invention provides an advanced treatment system for industrial wastewater, such as figure 1 As shown, it includes a sequentially connected adjustment tank for removing impurities in industrial wastewater and adjusting the pH value of industrial wastewater 1, a reactive sedimentation tank 11 for removing heavy metal ions in industrial wastewater, using microorganisms to degrade organic matter in industrial wastewater and having denitrification and removal Phosphorus aerobic tank 20, anaerobic tank 28 for removing organic matter in industrial sewage, secondary sedimentation tank 32, filtering device 33, detection tank 37 and disinfection tank 38, disinfection tank 38 is provided with standard discharge pipelines. The reaction sedimentation tank 11, the aerobic tank 20, the anaerobic tank 28, and the secondary sedimentation tank 32 are respectively connected to a sludge thickening tank 39 for mixing and thickening sludge through pipelines. The sludge thickening tank 39 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com