A heat treatment method for electric arc additive manufacturing of high-strength titanium alloy and a reinforced high-strength titanium alloy

A heat treatment method and additive manufacturing technology, applied in the field of titanium alloys, can solve problems such as complex manufacturing process, large grain size, and complex forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of TC11 high-strength titanium alloy sample:

[0044] Use TC11 high-strength titanium alloy wire with a diameter of 1.2mm as raw material to prepare TC11 high-strength titanium alloy sample. Specifically, connect the positive electrode of a hot wire power supply at a distance of 30cm from the melting end of the TC11 high-strength titanium alloy wire, and connect the hot wire The negative pole of the power supply is connected to the workbench to provide auxiliary heating for the TC11 high-strength titanium alloy wire during the arc additive manufacturing process. The specific arc additive manufacturing parameters are as follows:

[0045] The peak current is 220A; the peak current time ratio is 15%; the base value current is 15% of the peak current; the frequency is 1.5Hz; the scan rate is 250mm / min; the wire feeding speed is 150cm / min; the layer height is 1.0mm; The hot wire current is 100A;

[0046] The size of the obtained sample is 175mm×50mm×80mm;

...

Embodiment 2

[0053] (1) Preparation of TC18 high-strength titanium alloy sample:

[0054] Prepare the TC18 high-strength titanium alloy sample according to the method of Example 1, the only difference is that the TC11 high-strength titanium alloy wire is replaced by the TC18 high-strength titanium alloy wire;

[0055] (2) Heat treatment:

[0056] The β phase transition point of TC18 high-strength titanium alloy is 880°C. The TC18 high-strength titanium alloy sample obtained in step (1) was heated to 900°C with the furnace at a heating rate of 10°C / min, kept for 30 minutes, and then heated at a temperature of 8°C / min. The cooling rate was cooled to 820°C with the furnace, kept for 1 hour, then air-cooled to room temperature, and then heated to 500°C with the furnace at a rate of 10°C / min and held for 6 hours, and then air-cooled to room temperature to obtain a reinforced TC18 high-strength titanium alloy.

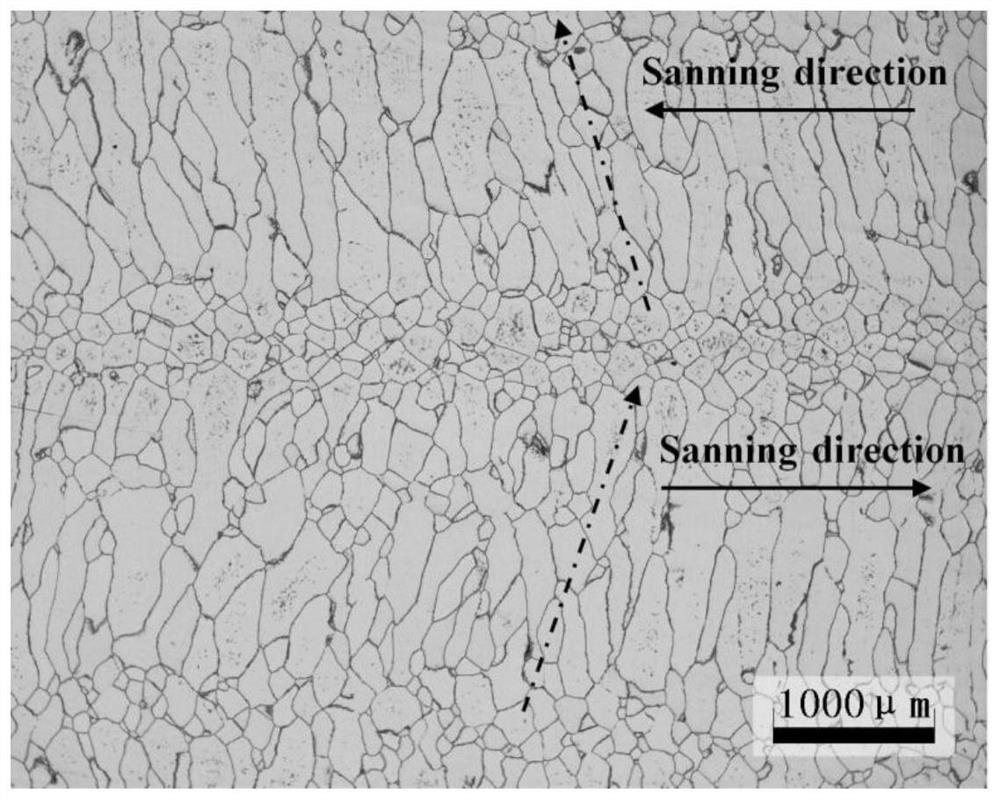

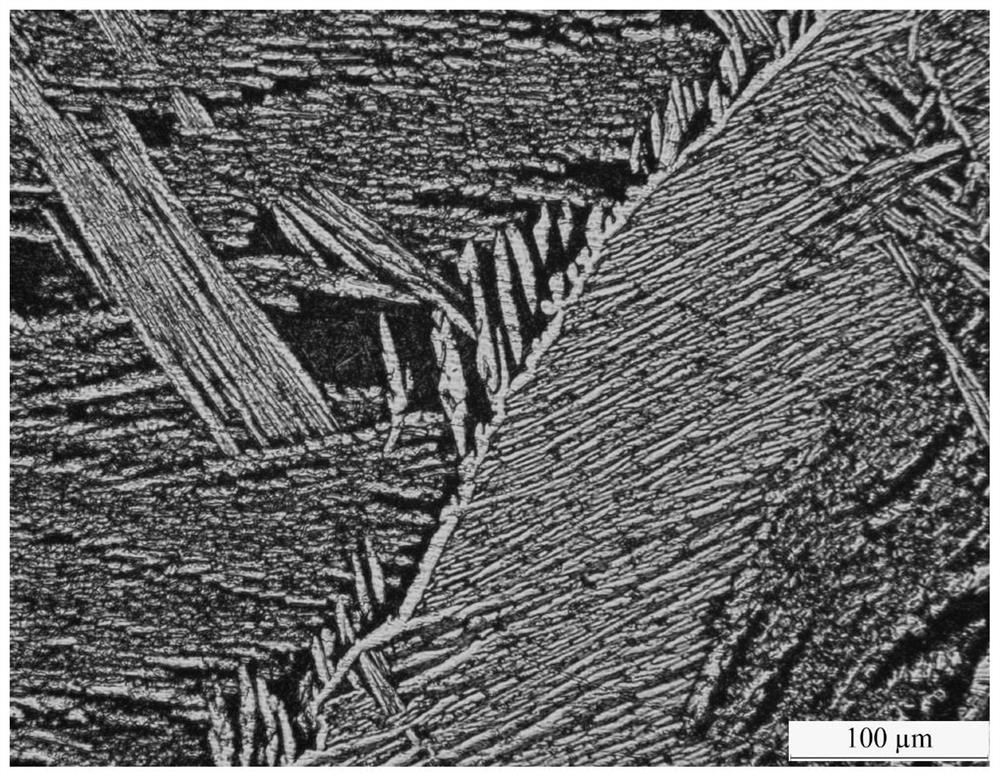

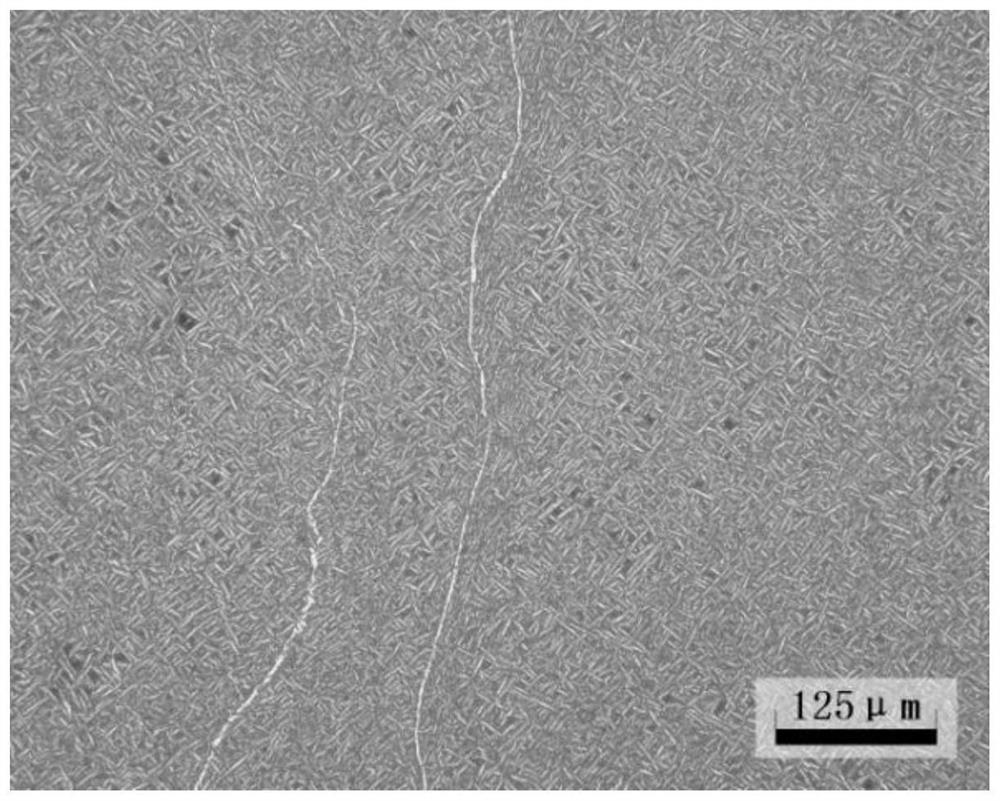

[0057] image 3 The microstructure figure of the TC18 high-strength titanium alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com