Reinforcement type rare earth electrolysis graphite crucible

An electrolytic graphite, enhanced technology, applied in the direction of electrolytic components, electrolytic process, electrodes, etc., can solve the problems of easy deviation of the falling track, reduce the purity of the metal, increase the difficulty of recycling, etc., to avoid residues inside the sphere, avoid residues, The effect of increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

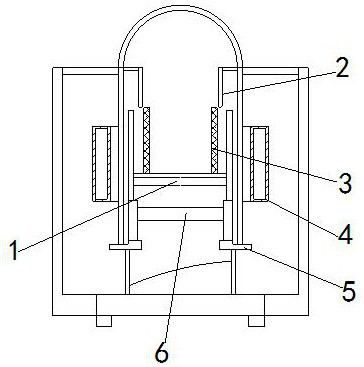

[0023] Such as Figure 1-Figure 5 Shown:

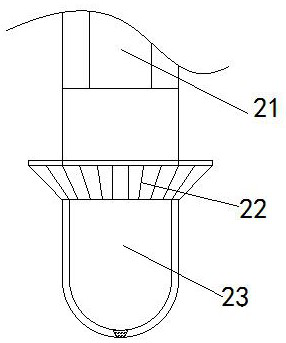

[0024] The present invention is an enhanced rare earth electrolytic graphite crucible, the structure of which includes a fixed plate 1, a cathode adsorption rod 2, graphite 3, a graphite anode sheet 4, a fixed frame 5, and a metal receiver 6, and the fixed plate 1 is installed on the fixed frame 5 The upper end of the upper end, the cathode adsorption rod 2 is located at the upper end of the graphite 3, the graphite anode sheet 4 is embedded in the upper end of the fixed frame 5, the metal receiver 6 is located at the inner side of the fixed frame 5, and the cathode adsorption rod 2 is set There are cathode magnetic bar 21, rotating device 22, and circulation mechanism 23, and described rotating device 22 is embedded in the lower end of cathode magnetic bar 21, and described circulation mechanism 23 is attached to the lower end of rotating device 22, and described cathode magnetic bar 21 is installed On the upper end of the fixed fra...

Embodiment 2

[0031] Such as Figure 6-Figure 7 Shown:

[0032]Wherein, the rotating device 22 is provided with a sliding rod w1, a sphere w2, and a sliding mechanism w3, the outer side of the sliding rod w1 is embedded in the inner side of the sphere w2, and the outer side of the sphere w2 is attached to the inner side of the stop ring a3 , the sliding rod w1 is installed on the lower end of the cathode magnet bar 21, there is a gap between the ball w2 and the sliding mechanism w3, and its surface is relatively smooth, which reduces friction, avoids the residue of rare earth liquid, and achieves that the rare earth liquid is collected When concentrated effect.

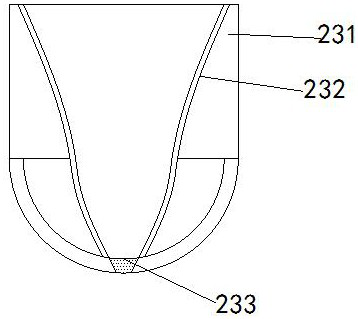

[0033] Wherein, the sliding mechanism w3 is provided with an inclined plate w31, a sliding plate w32, and a stressed plate w33, the lower end of the inclined plate w31 is attached to the surface of the stressed plate w33, and the stressed plate w33 and the sliding plate w32 are Integrated structure, the left side of the sliding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com