Aftertreatment device for motor vehicle exhaust and use method

A technology for exhaust gas post-processing and motor vehicles, which is applied in exhaust devices, noise reduction devices, machines/engines, etc., and can solve problems such as increased pollution gas, blockage of exhaust pipes, and health hazards, and achieves enhanced catalytic effects and increased The contact area and the effect of enhancing the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

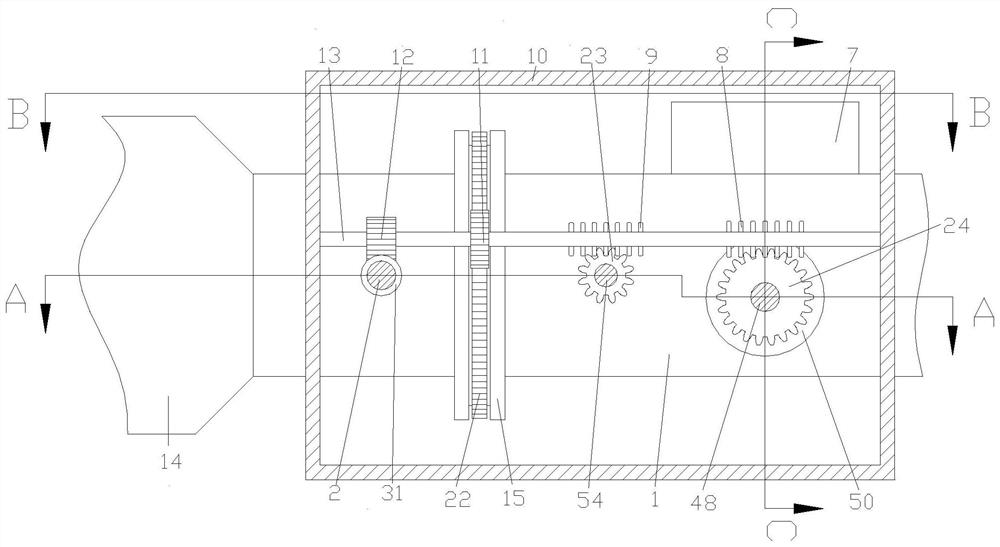

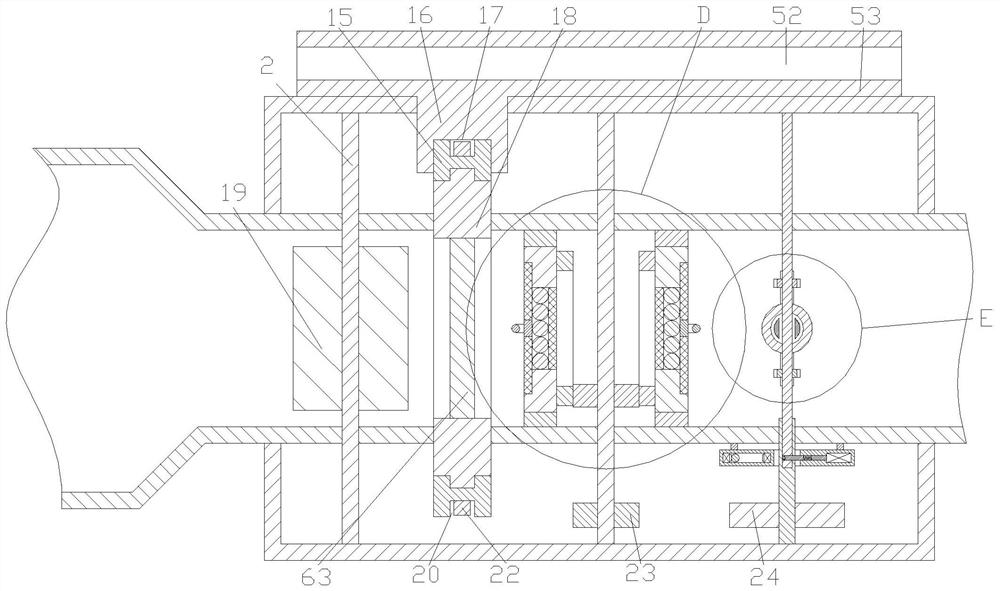

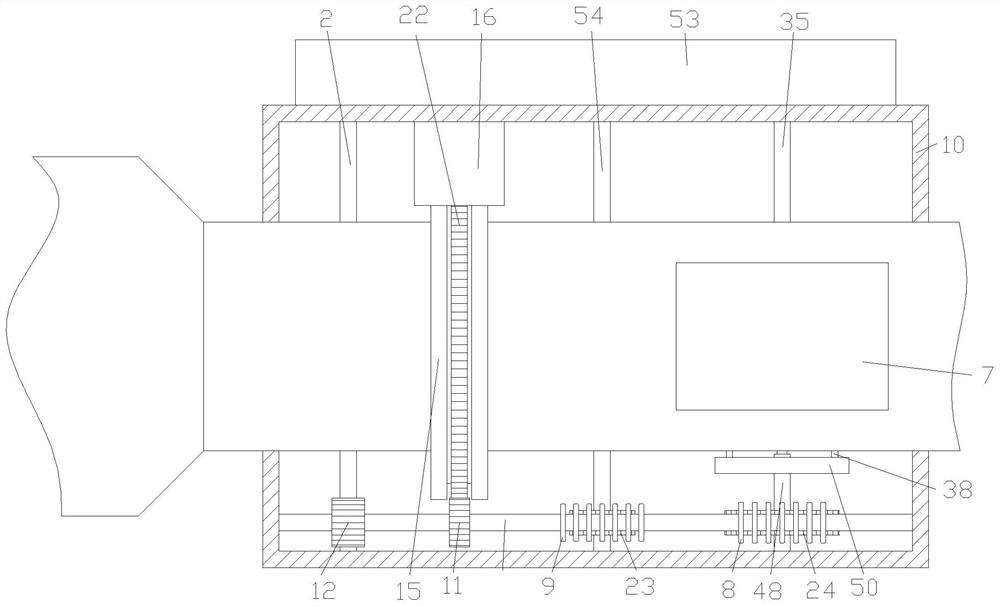

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] Refer to attached Figure 1-11 : In the present embodiment, this motor vehicle exhaust aftertreatment device comprises a first square pipe 1, a second square pipe 10 is fixedly installed on the outside of the first square pipe 1, and a first square pipe 1 is installed at one end of the first square pipe 1. Round pipe 14, the inside of the first square pipe 1 is symmetrically provided with a circular plate 61, and the outer side of the circular plate 61 is rotatably connected with a first support plate 56 fixedly connected to the inner wall of the first square pipe 1, and between the circular plates 61 After passing through the first square tube 1, the first rotating shaft 54 that is rotatably connected to the inner walls of the front and rear ends of the second square tube 10, the center of the circular plate 61 is provided with a through first installation groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com