Rare earth electroluminescent blue light device

A rare earth and device technology, applied in the field of rare earth electro-optical blue light devices, can solve the problems of easy aging, poor stability of organic matter, blue light color distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

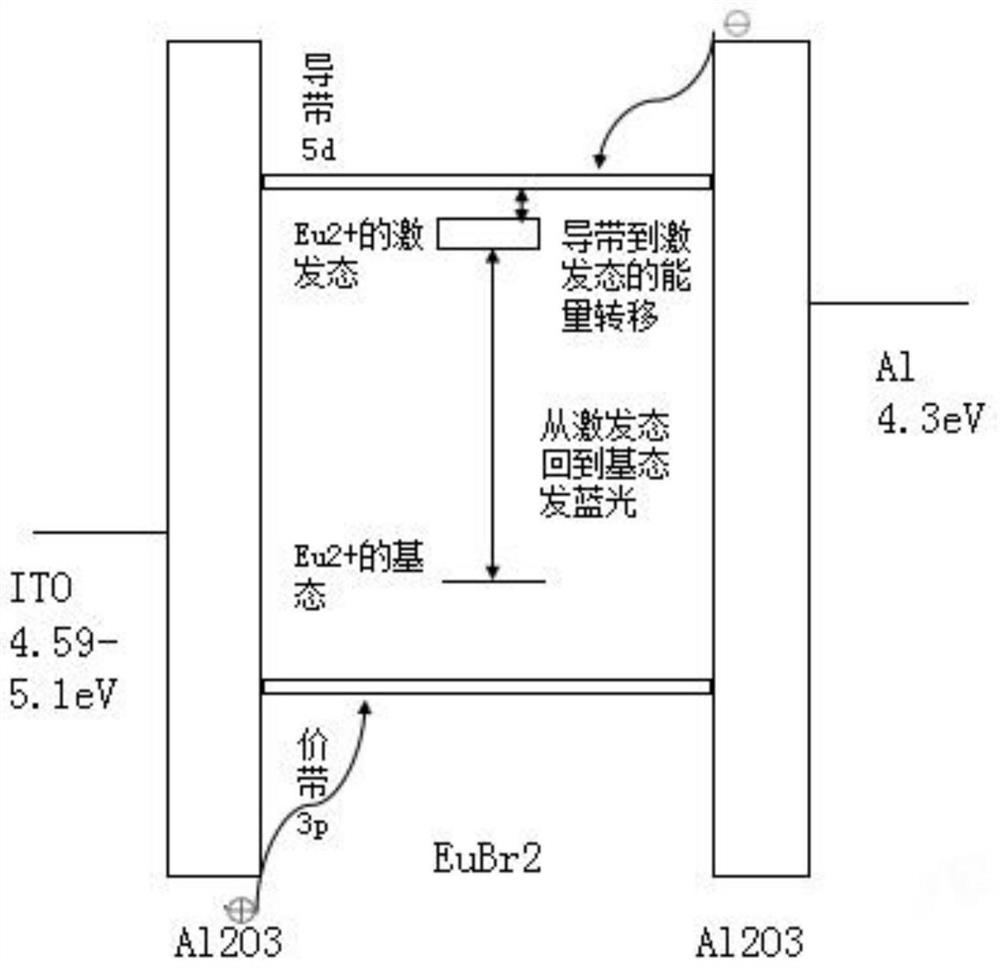

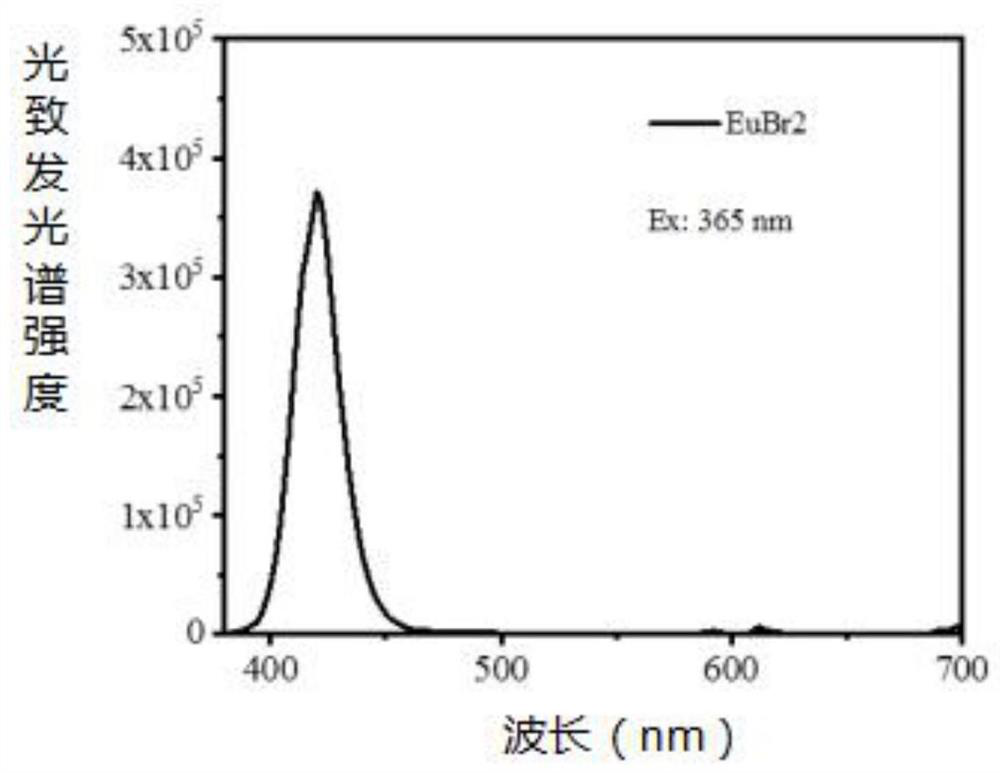

[0040] In this embodiment, the light-emitting layer material is EuBr 2 , functional layer material is Al 2 o 3 Taking the electroluminescent blue light device of high dielectric constant material as an example, its specific preparation method includes the following steps:

[0041] a) Use detergent, deionized water, acetone and absolute ethanol to ultrasonically clean the substrate ITO in sequence, for half an hour each time; where, ITO uses a substrate that has been etched two times, and its light-emitting area is about 2mm*2mm;

[0042] b) Depositing Al on ITO by atomic layer deposition (Atomic layer deposition, ALD) process 2 o 3 thin film, about 3nm thick;

[0043] c) will be plated Al 2 o 3 The substrate of the film is placed in the evaporation glove box, and the vacuum degree is evacuated to 4*10 -5 Below Pa, evaporate EuBr at a speed of 0.1nm / s 2 Thin films were evaporated to a thickness of 100nm in total. After the evaporation is completed, take the substrate i...

Embodiment 2

[0047] In this embodiment, the light-emitting layer material is CsEuBr 3 , functional layer material is Al 2 o 3 Taking the electroluminescent blue light device of high dielectric constant material as an example, its specific preparation method includes the following steps:

[0048] a) Ultrasonic cleaning the ITO substrate with detergent, deionized water, acetone and absolute ethanol in sequence, half an hour each time; among them, ITO uses a substrate that has been etched two times, and its light-emitting area is about 2mm*2mm;

[0049] b) Depositing Al on ITO by ALD process 2 o 3 thin film, about 3nm thick;

[0050] c) will be plated Al 2 o 3 The substrate of the film is placed in the evaporation glove box, and the vacuum degree is evacuated to 4*10 -5 Below Pa, use the double-source co-evaporation method to evaporate EuBr at a speed of 0.1nm / s 2 Thin film, evaporate a CsBr thin film at a speed of 0.1nm / s, with a total thickness of 100nm; after the evaporation is com...

Embodiment 3

[0054] In this embodiment, the light-emitting layer material is Cs 2 EuBr 4 , functional layer material is Al 2 o 3 Taking the electroluminescent blue light device of high dielectric constant material as an example, its specific preparation method includes the following steps:

[0055] a) Use detergent, deionized water, acetone and absolute ethanol to ultrasonically clean the substrate ITO in sequence, for half an hour each time; where, ITO uses a substrate that has been etched two times, and its light-emitting area is about 2mm*2mm;

[0056] b) Depositing Al on ITO by ALD process 2 o 3 thin film, about 3nm thick;

[0057] c) will be plated Al 2 o 3 The substrate of the film is placed in the evaporation glove box, and the vacuum degree is evacuated to 4*10 -5 Below Pa, use the double-source co-evaporation method to evaporate EuBr at a speed of 0.1nm / s 2 For the thin film, a CsBr thin film was evaporated at a speed of 0.2nm / s, and a total thickness of 100nm was evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com