Composite forming die and method for titanium alloy deep-cavity component

A forming die and composite forming technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as wrinkling and cracking, poor forming accuracy, and many forming passes, so as to reduce the resistance of moving deformation and improve the wall thickness. Thickness uniformity, effect of reducing wall thickness reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

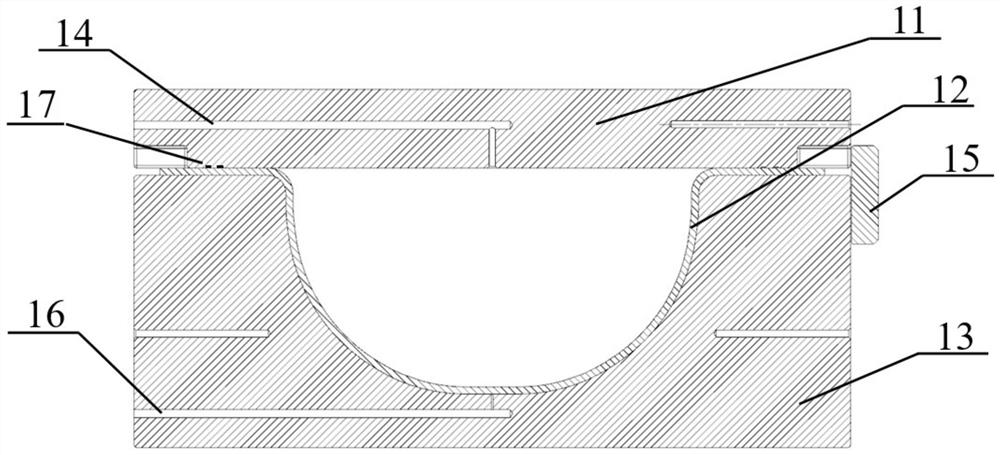

[0072] Taking TA15 titanium alloy hemispherical deep-drawing parts as an example, its dimensions are shown in image 3 , the component thickness is 4mm, and the total height is 320mm.

[0073] The specific forming process is carried out as follows:

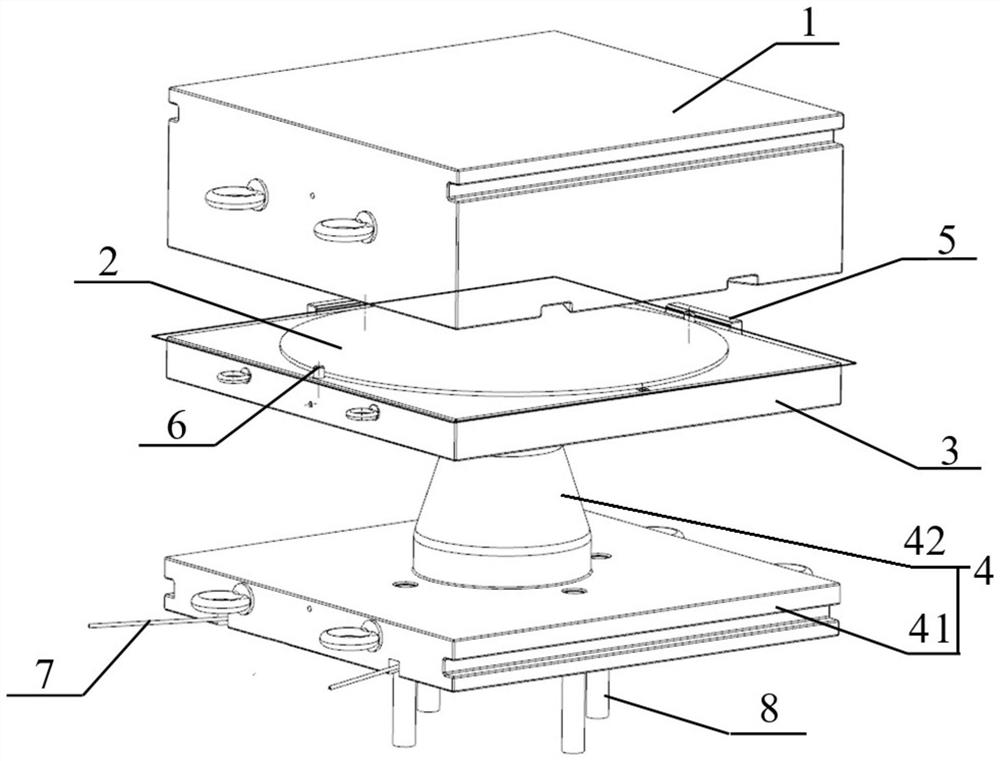

[0074] Step (1) Determine the size of the blank: select the 7mm thick TA15 titanium alloy raw material plate required for forming, and supplement the margin and process flange edge according to the characteristics of the component (such as figure 1 Shown), unfold and confirm that the blanking size is 7×Φ900mm.

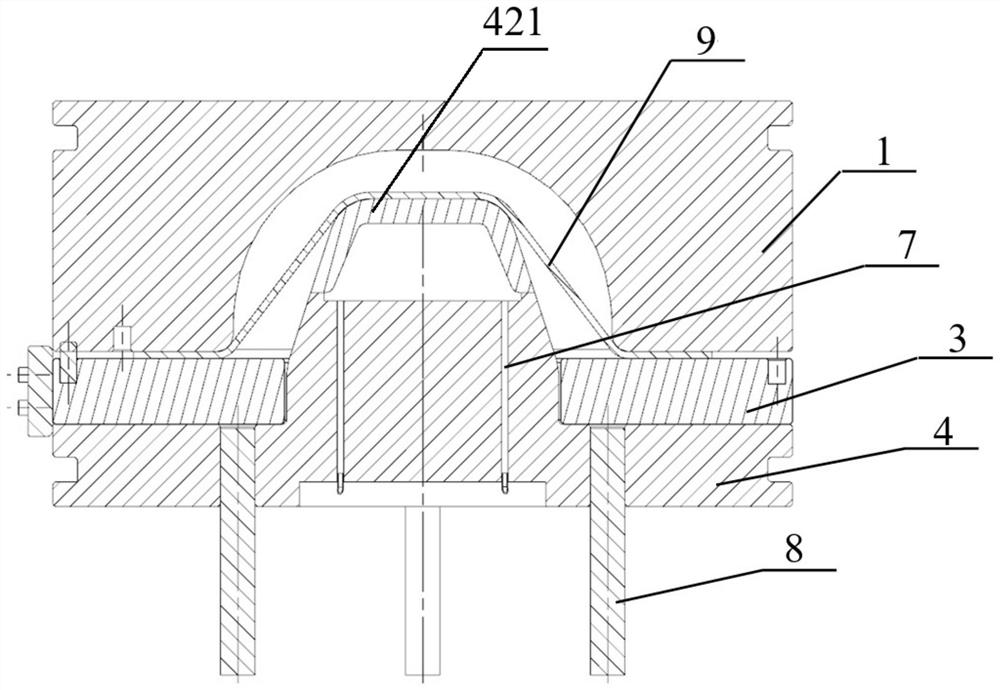

[0075] Step (2) Designing the forming mold: designing and manufacturing the required molds for thermal deep drawing forming and superplastic forming, appropriately reducing the cavity of the superplastic forming mold according to the size of the titanium alloy hemispherical component, and selecting the scaling factor as 8‰.

[0076] Step (3) Forming preparation: Only the flange position of the drawing upper die and blank...

Embodiment 2

[0081] Taking TC4 titanium alloy hemispherical deep-drawing parts as an example, its dimensions are shown in image 3 , the component thickness is 3mm, and the total height is 270mm.

[0082] The specific forming process is carried out as follows:

[0083] Step (1) Determine the size of the blank: select the 6mm thick TC4 titanium alloy raw material plate required for forming, and supplement the margin and process flange edge according to the characteristics of the component (such as figure 1 Shown), expand to determine the blanking size is 6 × Φ800mm.

[0084] Step (2) Designing the forming mold: designing and manufacturing the required molds for thermal deep drawing forming and superplastic forming, appropriately reducing the cavity of the superplastic forming mold according to the size of the titanium alloy hemispherical component, and selecting the scaling factor as 8‰.

[0085]Step (3) Forming preparation: Only the flange position of the drawing upper die and blank hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com