A kind of pvc power protection composite pipe and preparation method thereof

A technology for power protection and PVC pipes, applied in chemical instruments and methods, tubular objects, electrolytic coatings, etc., can solve the problems of insufficient termite protection, complex and cumbersome bottoming process, and insufficient hardness of the porous layer, so as to achieve easy implementation and prevent The effect of peeling and good containment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

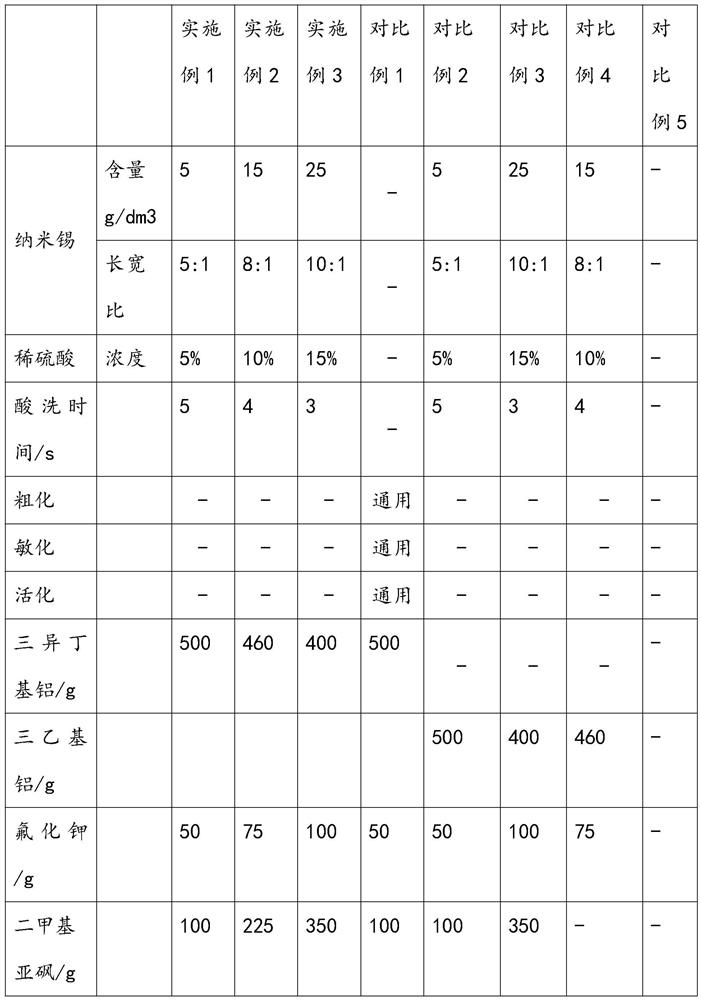

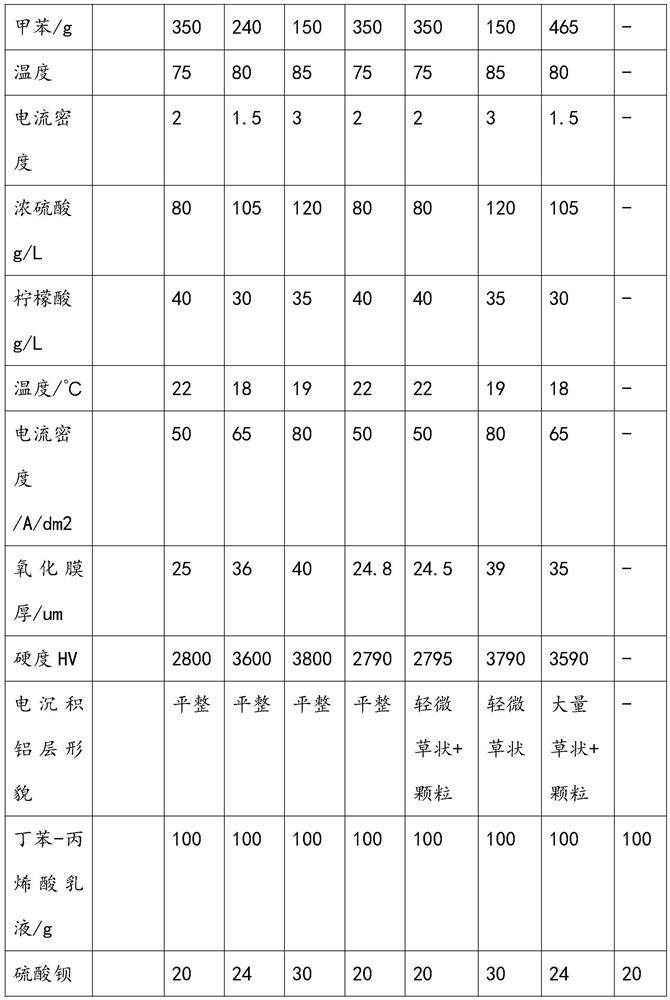

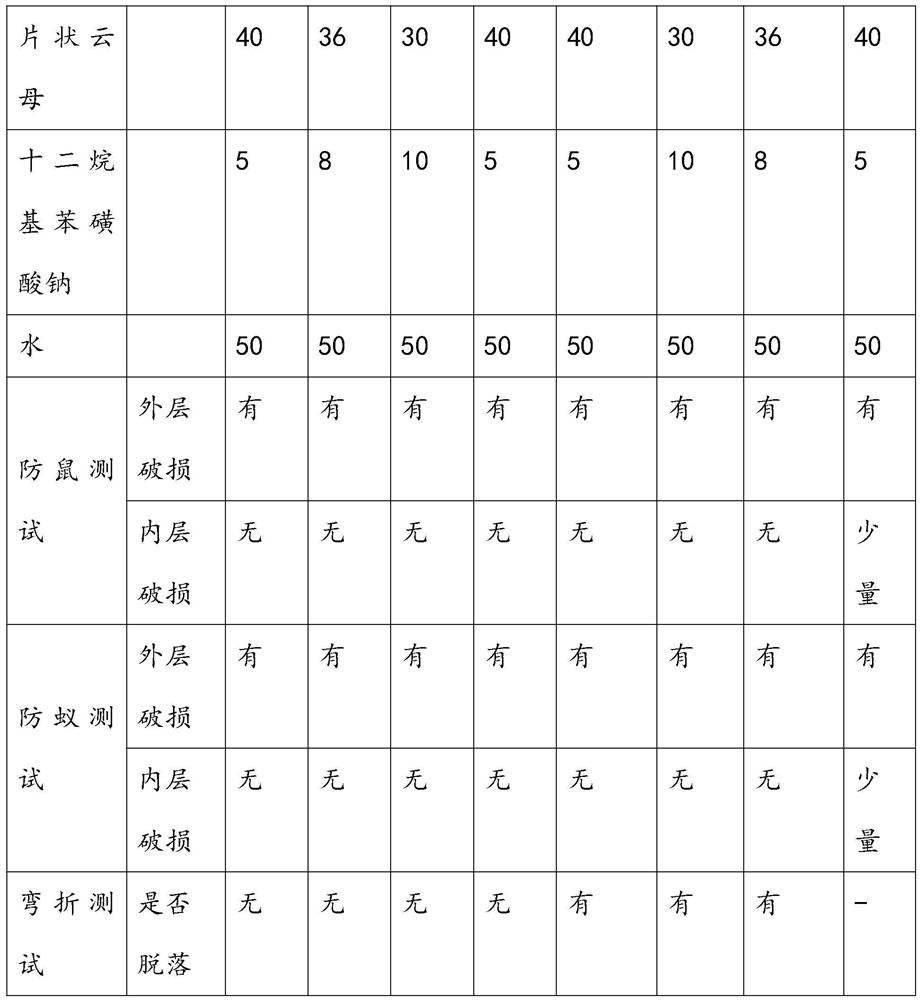

Examples

Embodiment 1

[0029] A PVC power protection composite pipe, from inside to outside, is an inner layer, a first intermediate layer, a second intermediate layer, a third intermediate layer and an outer layer, the inner layer is a PVC pipe layer, and the outer layer is a protective layer, Wherein the first intermediate layer is a PVC layer containing nano-tin, the second intermediate layer aluminum thin layer, the third intermediate layer is a porous alumina layer, and the preparation method of the composite pipe is as follows:

[0030] (1) Select a commercially available PVC power protection pipe as the inner layer pipe, or prepare the inner layer PVC pipe according to the general power protection pipe method;

[0031] (2) compound the PVC pipe base material containing tin powder on the inner layer pipe according to the general method for preparing pipe material; pass the PVC pipe containing the nano-tin first intermediate layer prepared in step 2 through the pickling tank quickly, and then pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com