Low-cost superfine basalt fiber

A basalt fiber and low-cost technology, which can be used in the manufacture of tools, glass manufacturing equipment, textiles and papermaking, etc., can solve the problems of difficult promotion and application, high price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

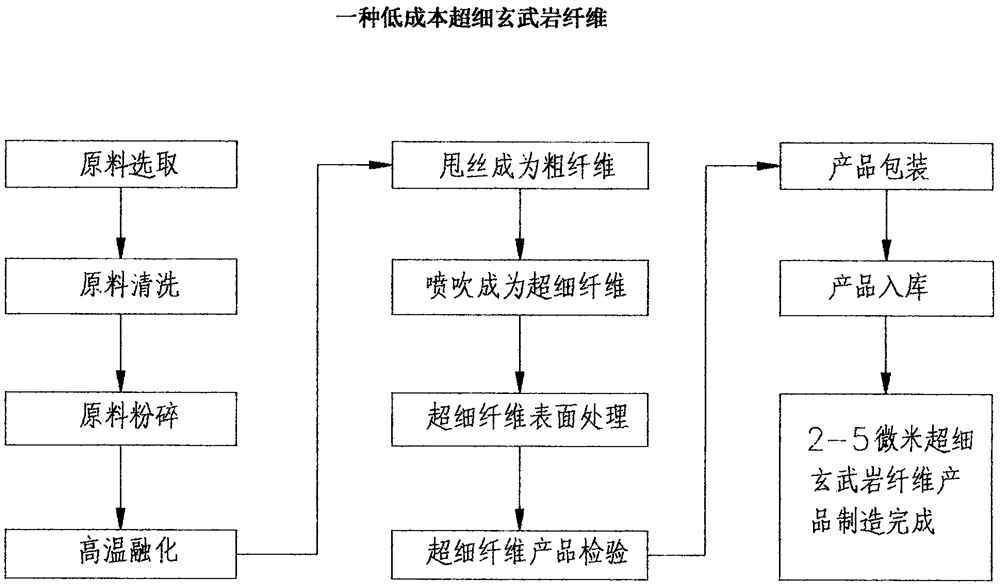

[0015] The specific embodiment is further described with reference to the accompanying drawings:

[0016] To produce ultra-fine basalt fiber, the first step is to select basalt ore raw materials, the selected basalt ore raw materials are sent to the cleaning area for cleaning, the cleaned basalt ore raw materials enter the crushing area for crushing, and the crushed basalt ore raw materials enter the Iron removal is carried out in the iron area, and the basalt ore after the iron removal is sent to a high-temperature melting furnace for melting. After the basalt is melted into a liquid state, it enters the orifice of the high-temperature melting furnace, and the liquid basalt flowing out of the ore of the high-temperature melting furnace flows by gravity. To the working surface of the high-speed wire-spinning machine, the high-temperature wire-spinning machine spins out the liquid basalt solution at high speed, and the liquid basalt that is thrown out is blown by high-pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com