Preparation method of high-emissivity LaMgAl11O19 ceramic

A technology of lamgal11o19 and high emissivity, which is applied in the field of preparation of high emissivity LaMgAl11O19 ceramics, can solve the problems that ceramics are difficult to meet emissivity requirements, limit application and promotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) La 2 o 3 Powder (average particle size 0.5μm, purity ≥ 99.9%), Al(OH) 3 Powder (average particle size 0.5μm, purity ≥ 99.9%) and Mg(OH) 2 The powder (average particle size is 0.5 μm, purity ≥ 98.0%) is compounded according to the stoichiometric ratio, and mixed by wet ball milling to obtain a uniformly mixed white mixed powder;

[0017] (2) Put the mixed powder into the mold, and then place the mold in a hot-press sintering furnace. In a vacuum environment, first heat it to 1100°C at a heating rate of 15°C / min, and then heat it at a heating rate of 10°C / min. Heating at a rate of 1500°C, at the same time starting from 1100°C and increasing the pressure to 40MPa at a rate of 1MPa / min, keeping the pressure at 1500°C and 40MPa for 2.5h, then cooling with the furnace to obtain a high emissivity LaMgAl 11 o 19 ceramics.

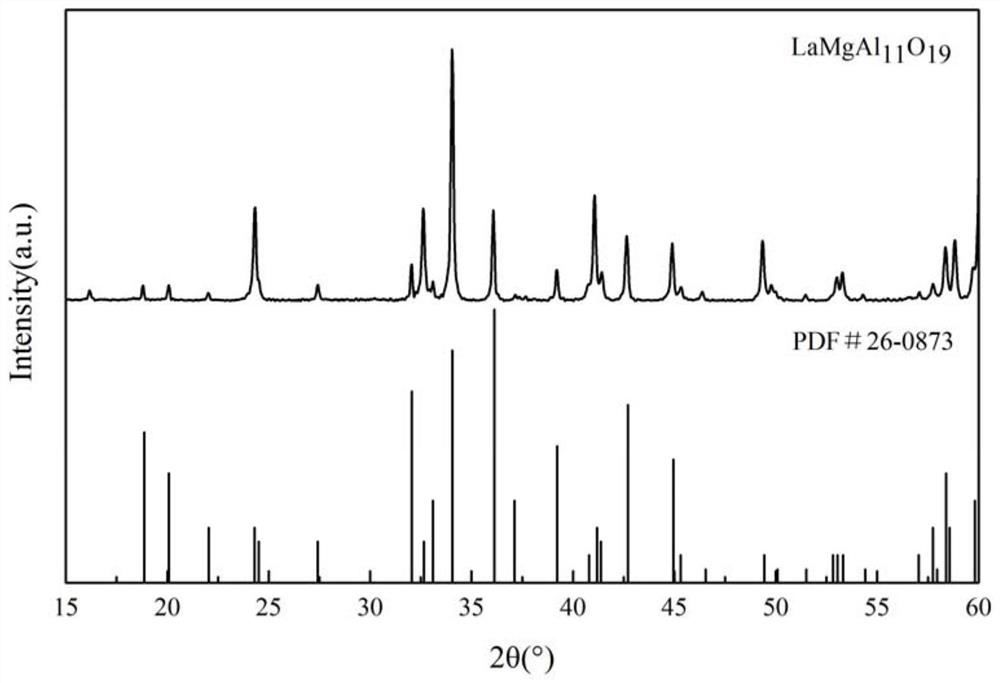

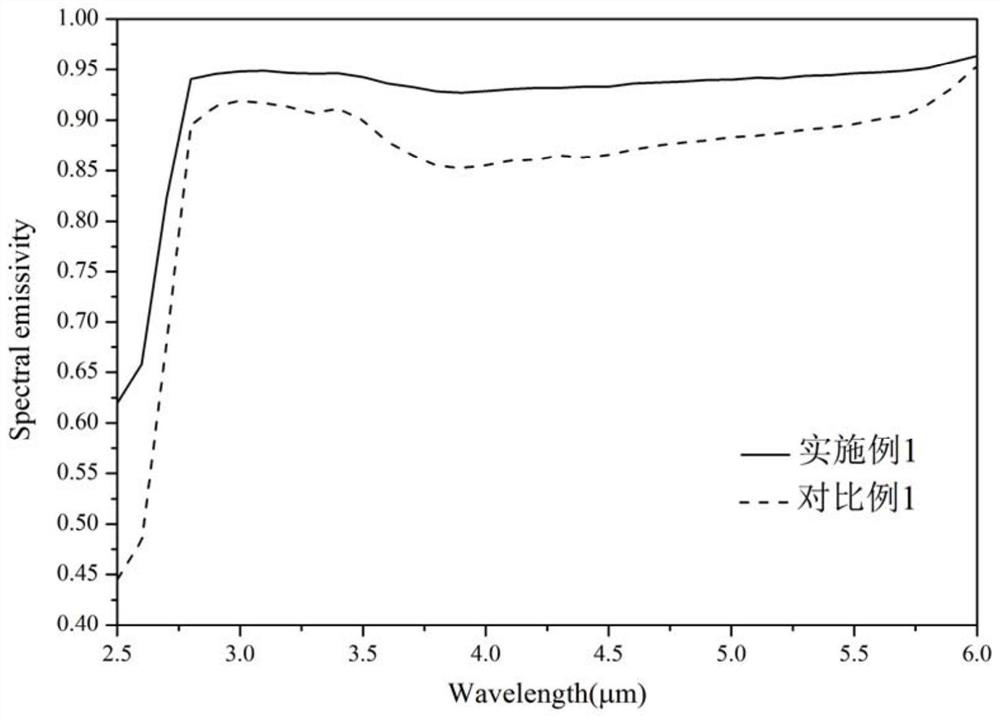

[0018] LaMgAl prepared in this embodiment 11 o 19 There are no micro-cracks on the surface of the ceramic, and it can be seen from its cross-sect...

Embodiment 2

[0021] (1) La 2 o 3 Powder (average particle size 0.5μm, purity ≥ 99.9%), Al(OH) 3 Powder (average particle size 0.5μm, purity ≥ 99.9%) and Mg(OH) 2 The powder (average particle size is 0.5 μm, purity ≥ 98.0%) is compounded according to the stoichiometric ratio, and mixed by wet ball milling to obtain a uniformly mixed white mixed powder;

[0022] (2) Put the mixed powder into the mold, and then place the mold in a hot-press sintering furnace. In a vacuum environment, first heat it to 950°C at a heating rate of 15°C / min, and then heat it at a heating rate of 10°C / min. Heating rate to 1400 ℃, and at the same time starting from 950 ℃ to increase the pressure to 45MPa at a rate of 1MPa / min, after holding the pressure at 1400 ℃ and 45MPa for 3 hours, cooling with the furnace to obtain high emissivity LaMgAl 11 o 19 ceramics.

[0023] LaMgAl prepared in this embodiment 11 o 19 There are no micro-cracks on the surface of the ceramic, and it can be seen from its cross-section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com