MB2-based ultrahigh-temperature ceramic coating and preparation method thereof

An ultra-high temperature ceramic, 60% MB2 technology, used in the field of ceramic coatings, can solve the problems of difficult to control thickness, poor coating uniformity, and low coating density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a MB 2 A method for preparing a base ultra-high temperature ceramic coating, comprising the following steps:

[0033] (1) Preparation of MB 2 Based ultra-high temperature ceramic agglomerated powder;

[0034] (2) Prepare the substrate for spraying;

[0035] (3) Preparation of MB on the surface of the substrate by supersonic plasma spraying 2 Base ultra-high temperature ceramic coating;

[0036] (3.1) Substrate pretreatment;

[0037] (3.2) Preparation of MB by supersonic plasma spraying 2 Base ultra-high temperature ceramic coating body.

[0038] In this scheme, optionally, in the preparation of MB by supersonic plasma spraying 2 After the body is coated with ultra-high temperature ceramics, the surface can be cleaned.

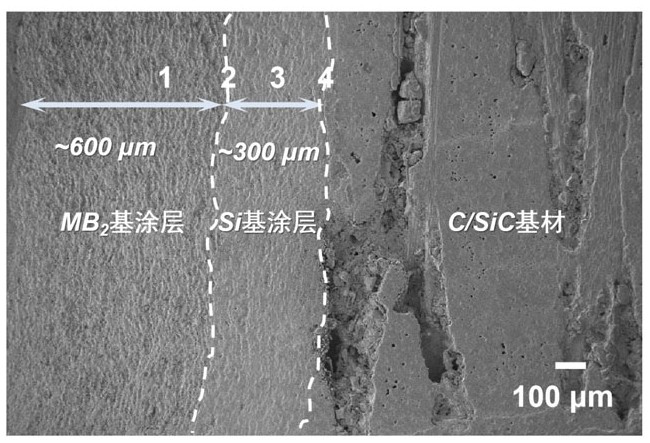

[0039] Preferably, before step (3.2), it also includes preparing a silicon-based transition layer on the surface of the substrate; the silicon-based transition layer is prepared by supersonic plasma spraying, s...

Embodiment 1

[0047] A MB of the present invention 2 (M=Zr, Hf)-based ultra-high temperature ceramic coating, the composition of which is MB 2 -M 1 Si-Mo-SiC, where MB 2 50% by volume, including HfB 2 , ZrB 2 , and by volume ratio, HfB 2 : ZrB 2 is 4:1; M 1 The volume fraction of Si is 25%, including MoSi 2 、CrSi 2 , ZrSi 2 and TaSi 2 , and by volume ratio, MoSi 2 : CrSi 2 : ZrSi 2 :TaSi 2 It is 1:1:1:1; the volume fraction of Mo is 20%; the volume fraction of SiC is 5%.

[0048] A MB of this embodiment 2 The preparation method of (M=Zr, Hf) base ultra-high temperature ceramic coating comprises the following steps:

[0049] (1) Add the raw materials according to the ratio of the coating design, with ZrO 2 As a grinding ball, resin arabic powder is used as a binder, and the amount used is 1% of the total mass of raw materials. The slurry is prepared by roller milling, the slurry is sprayed and granulated, and the agglomerates with a particle size of 20-80 μm are collected ...

Embodiment 2

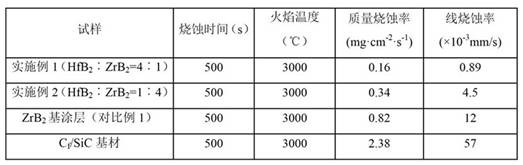

[0058] The difference between this embodiment and embodiment 1 is that in the coating composition, and by volume ratio, HfB 2 : ZrB 2 It is 1:4.

[0059] MB of this embodiment 2 The ablation test results of (M=Zr, Hf) based ultra-high temperature ceramic coatings are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com