Large-color-point sand-in-water base paint, preparation method and large-color-point sand-in-water coating

A technology of sand-in-water paint and basic paint, which is applied in the field of imitation stone materials, can solve the problems that stone is difficult to imitate, the degree of simulation of color and texture is difficult to break through, and the application is limited. It achieves unique rheology, good water solubility, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

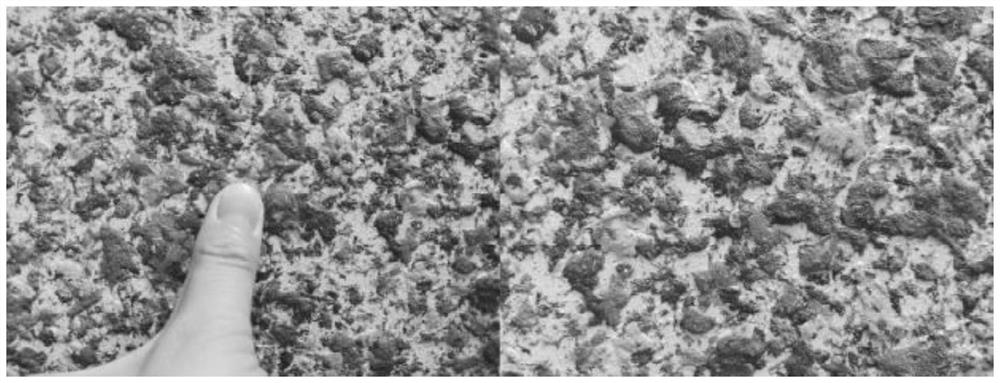

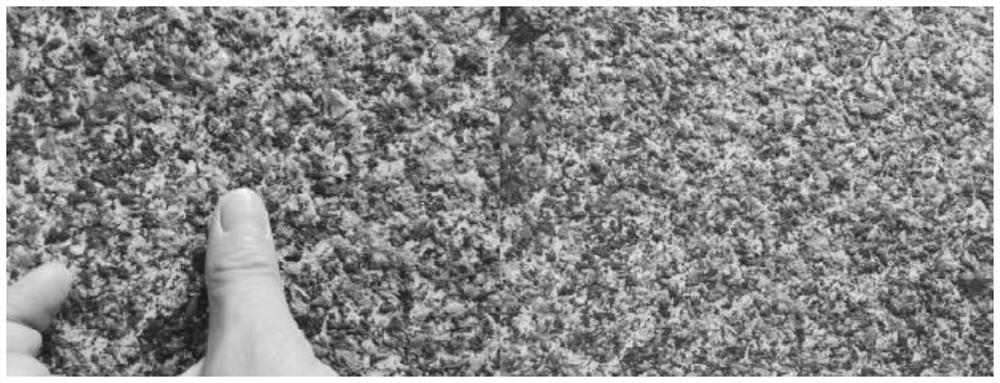

Image

Examples

Embodiment 1

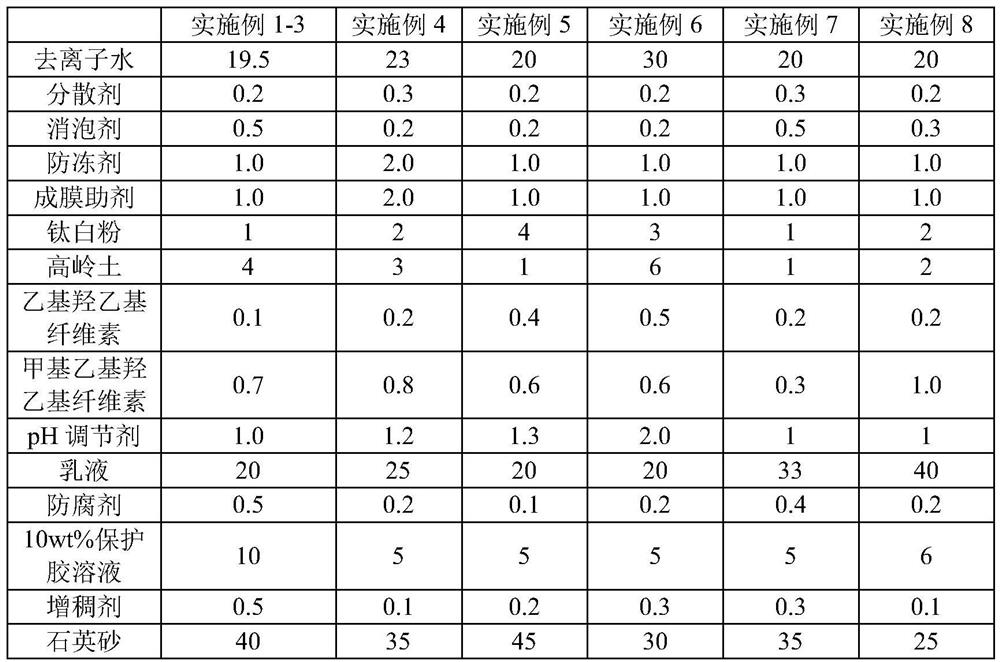

[0033] A large color point sand-in-water base paint, which is obtained through the following processing steps:

[0034] According to the dosage shown in Table 1, add deionized water to the mixer, and at a speed of 300r / min, add dispersant, defoamer, antifreeze, film-forming aid, titanium dioxide, kaolin, ethyl hydroxyl Ethyl cellulose and methyl ethyl hydroxyethyl cellulose were stirred and dispersed for 8 minutes; a pH regulator was added and stirred and dispersed for 20 minutes at a speed of 1200r / min to obtain a mixture A; at a speed of 800r / min, the Add emulsion, preservative, 10wt% protective colloid solution, thickener and 80-120 mesh quartz sand to the mixture A in sequence, and stir and disperse for 8 minutes at a speed of 800r / min to obtain a large color dot sand-in-water base paint.

Embodiment 2

[0036] A large color point sand-in-water base paint, which is obtained through the following processing steps:

[0037] According to the dosage shown in Table 1, add deionized water into the mixer, and at a speed of 400r / min, add dispersant, defoamer, antifreeze, film-forming aid, titanium dioxide, kaolin, ethyl hydroxyl Ethyl cellulose and methyl ethyl hydroxyethyl cellulose were stirred and dispersed for 5 minutes; a pH regulator was added and stirred and dispersed for 15 minutes at a speed of 1300r / min to obtain a mixture A; at a speed of 900r / min, the Add emulsion, preservative, 10wt% protective colloid solution, thickener and 80-120 mesh quartz sand to the mixture A in turn, and stir and disperse for 5 minutes at a speed of 900r / min to obtain a large color dot sand-in-water base paint.

Embodiment 3

[0039] A large color point sand-in-water base paint, which is obtained through the following processing steps:

[0040] According to the dosage shown in Table 1, add deionized water into the mixer, and at a speed of 500r / min, add dispersant, defoamer, antifreeze, film-forming aid, titanium dioxide, kaolin, ethyl hydroxyl Ethyl cellulose and methyl ethyl hydroxyethyl cellulose were stirred and dispersed for 10 minutes; a pH regulator was added, and stirred and dispersed for 25 minutes at a speed of 1500r / min to obtain a mixture A; at a speed of 1000r / min, the Add emulsion, preservative, 10wt% protective colloid solution, thickener and 80-120 mesh quartz sand to the mixture A in turn, and stir and disperse for 10 minutes at a speed of 1000r / min to obtain a large color point sand-in-water base paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com