Method for producing hexadecanedioic acid through fermentation, and hexadecanedioic acid and preparation method of hexadecanedioic acid

A dibasic acid and sixteen carbon technology, applied in the field of fermentation, can solve the problems of high sewage treatment cost, low production efficiency, large alkali consumption, etc., and achieve the effect of reducing sewage treatment cost, shortening production cycle and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

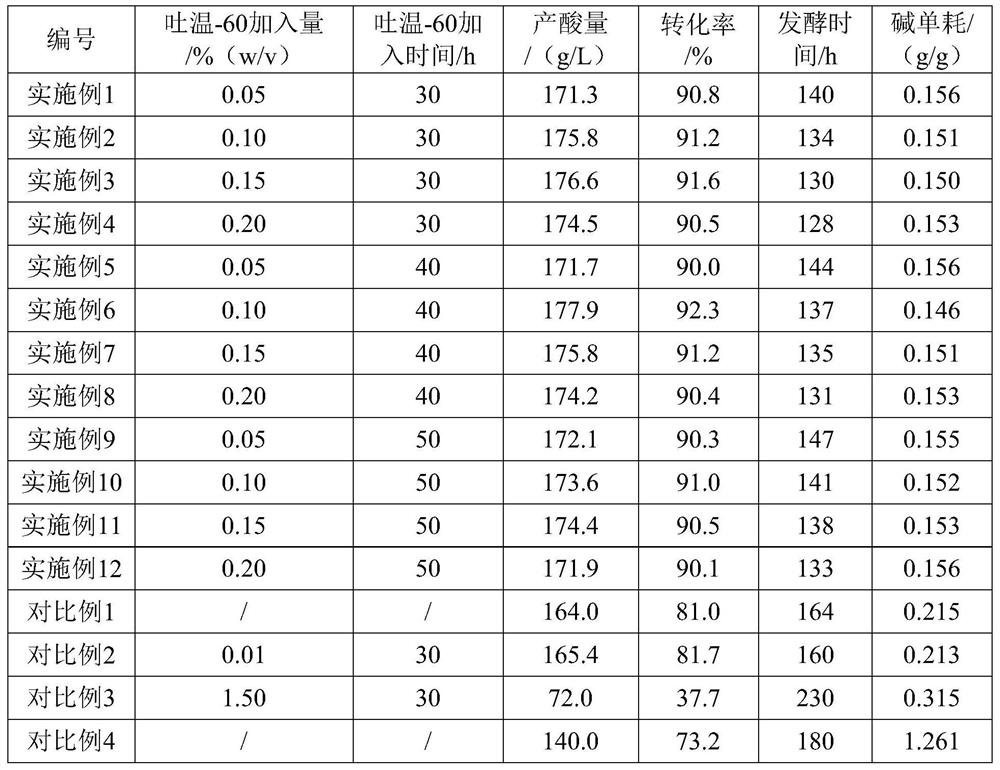

Embodiment 1~12

[0056] Embodiments 1 to 12 each provide a method for producing hexadecanoic acid by fermentation, which is to use Candida sake (Candidasake) CAT H4014 in a 10L fermenter, and add 0.05% to 0.20% when the fermentation starts 30 to 50 hours Tween-60 specifically comprises the following steps:

[0057] 1. First adjust the pH value of the 10 Baume wort to about 5.4, then take 80mL into a 500mL Erlenmeyer flask, sterilize at 121°C for 20min, and then insert it into the previously stored in a -80°C refrigerator One seed of Candidasake (Candidasake) in a 2mL glycerol tube was activated and cultured on a rotary shaker at a temperature of 29°C and a rotation speed of 250rpm for 40-44h, and the cell OD 620 When the value reaches above 0.5 (diluted 30 times), the activation culture ends.

[0058] 2. Insert the shake flask seeds obtained in the above step 1 into the seed tank containing the seed medium and cultivate them. The inoculum size is 1.33%, and the temperature during the cultivat...

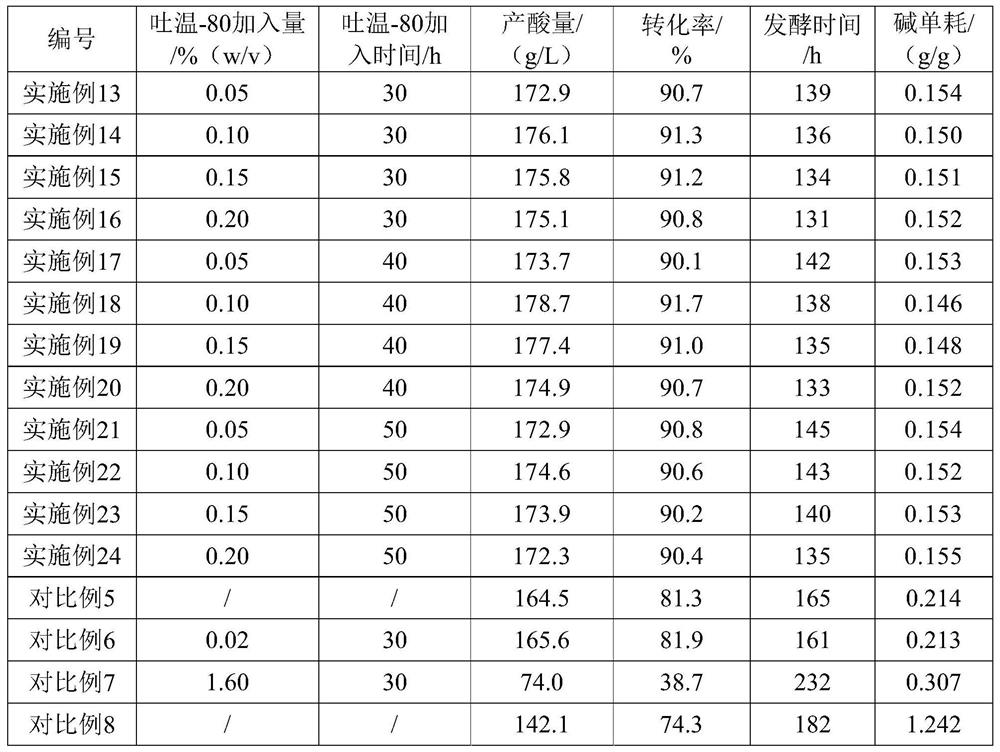

Embodiment 13~24

[0083] Examples 13-24 each provide a method for fermenting and producing hexadecanoic acid, using Candida Tropicalis CAT H1614 in a 10L fermenter, and adding 0.05-0.20% Tween-80 specifically comprises the following steps:

[0084] 1. First adjust the pH value of the 10 Baume wort to about 5.4, then take 80mL into a 500mL Erlenmeyer flask, sterilize at 121°C for 20min, and then insert it into the previously stored in a -80°C refrigerator One seed of Candida Tropicalis in a 2mL glycerol tube was activated and cultured on a rotary shaker at a temperature of 29°C and a rotation speed of 250rpm for 40-44h, and the OD of the bacteria was 620 When the value reaches above 0.5 (diluted 30 times), the activation culture ends.

[0085] 2. Insert the shake flask seeds obtained in the above step 1 into the seed tank containing the seed medium and cultivate them. The inoculum size is 1.33%, and the temperature during the cultivation process is controlled to be 29°C, the air volume is 0.3vv...

Embodiment 25

[0111] Example 25 provides a method for fermenting and producing hexadecanoic acid, using Candidasake CAT H4014 in a 200 cubic meter fermenter, except that 0.10% Tween-60 is added at 40 hours of fermentation , other process conditions are consistent with embodiment 1.

[0112] When 0.10% Tween-60 is added to the fermentation broth, during the process of adding n-hexadecane to carry out fermentation and conversion, the emulsification layer in the fermentation broth is observed by sampling, and it is found that the emulsification layer in the fermentation broth after adding Tween-60 more.

[0113] After the fermentation was stopped, the fermentation period was 136 hours, and the fermentation liquid was detected, and the content of hexadecanoic acid in the fermentation liquid was 178.3 g / L, and the conversion rate was 88.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com