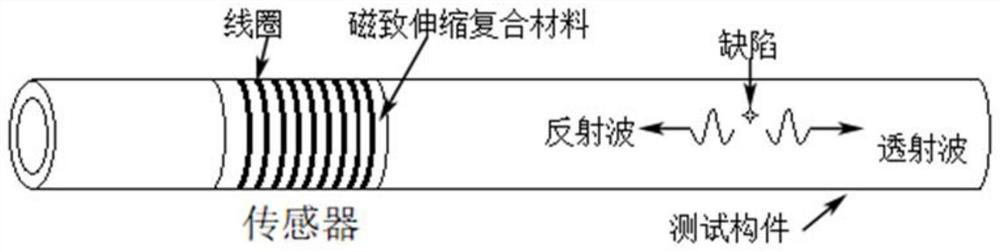

Magnetostrictive composite material for guided wave detection and its preparation method and application

A magnetostrictive and composite material technology, applied in the field of materials, can solve the problems of low resistivity and excessive hardness and brittleness, and achieve the effect of increasing resistivity, reducing production costs, and overcoming the inability to be used for higher frequencies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The embodiment of the present application also provides a preparation method of the magnetostrictive composite material, comprising the following steps:

[0042] uniformly mixing the terbium-dysprosium-iron alloy powder, the epoxy resin and the dispersant to form a premix;

[0043] The curing agent is kept separate from the premix.

[0044] The magnetostrictive composite material in this embodiment is actually a two-component material, including a curing agent and a premix. When using the magnetostrictive composite material for guided wave flaw detection, the curing agent and the premixture can be mixed in real time, and the mixture is loaded on the surface of the device to be tested to form a cured magnetostrictive composite material for guided wave detection.

[0045] In some embodiments, the composition of the magnetostrictive composite material also includes polydimethylsiloxane and / or rigidity modifier, and polydimethylsiloxane and / or rigidity modifier can be unif...

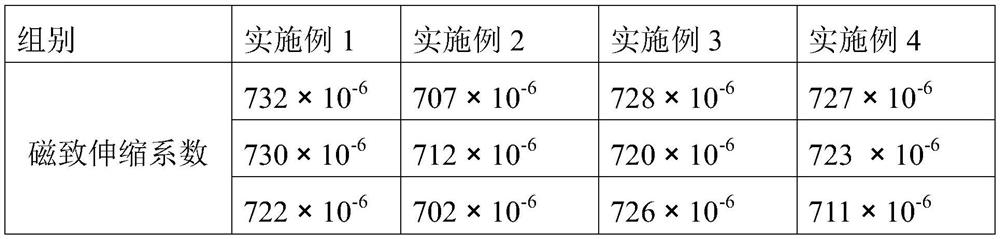

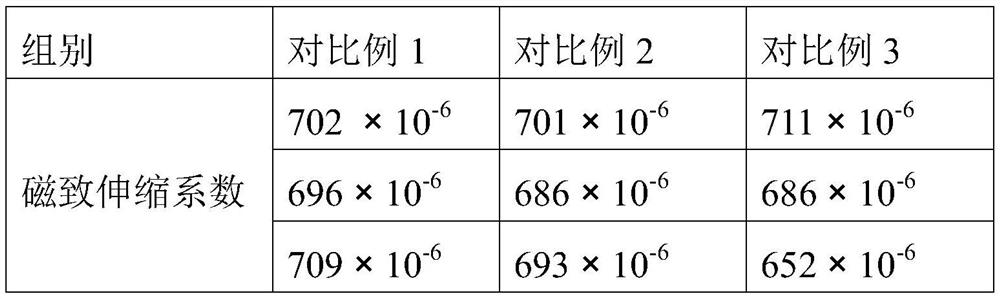

Embodiment 1

[0058] Alloy components of pure metal iron, terbium and dysprosium with a purity of 99.99% are put into the copper crucible from bottom to top according to the proportion of each component and melting point from high to low. Close the oven door and apply a vacuum. When the vacuum reaches 2×10 -3 At Pa, turn on the magnetic field current source to carry out magnetic levitation melting. The initial current is 40A, and the applied current increases from low to high, and increases by 20A until the metal is completely melted, showing a state of suspension melting, and the current is between 120-160A. The molten state lasts for 2-3 minutes, turn off the magnetic levitation current, and after the alloy is cooled by water, turn the alloy ingot over, and then continue to smelt as described above. After smelting 3 times, pour the liquid molten alloy. The prepared Tb 0.27 Dy 0.73 Fe 2 The alloy is mechanically crushed + jet mill + sand mill (ball mill) to obtain Tb with a particle s...

Embodiment 2

[0061] Alloy components of pure metal iron, terbium and dysprosium with a purity of 99.99% are put into the copper crucible from bottom to top according to the proportion of each component and melting point from high to low. Close the oven door and apply a vacuum. When the vacuum reaches 2×10 -3 At Pa, turn on the magnetic field current source to carry out magnetic levitation melting. The initial current is 40A, and the applied current increases from low to high, and increases by 20A until the metal is completely melted, showing a state of suspension melting, and the current is between 120-160A. The molten state lasts for 2-3 minutes, turn off the magnetic levitation current, and after the alloy is cooled by water, turn the alloy ingot over, and then continue to smelt as described above. After smelting 3 times, pour the liquid molten alloy. The prepared Tb 0.3 Dy 0.7 Fe 1.8 The alloy is prepared by gas atomization. The alloy is heated to 150-200 degrees Celsius above the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com