High gloss decorative rhodium plating layer plating solution

An electroplating solution and decorative technology, applied in the field of high-gloss decorative rhodium plating layer electroplating solution, can solve problems such as poor color tone, and achieve the effect of simple formula, stable performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of high-gloss decorative rhodium-plated layer electroplating solution, this electroplating solution is mixed by the component of following concentration: metal rhodium mass volume content is the rhodium sulfate solution of 1g / L, and mass volume concentration is 40g / L sulfuric acid solution, mass The polyethylene glycol whose volume concentration is 0.1g / L, and the quinoline oxide whose mass volume concentration is 0.1g / L.

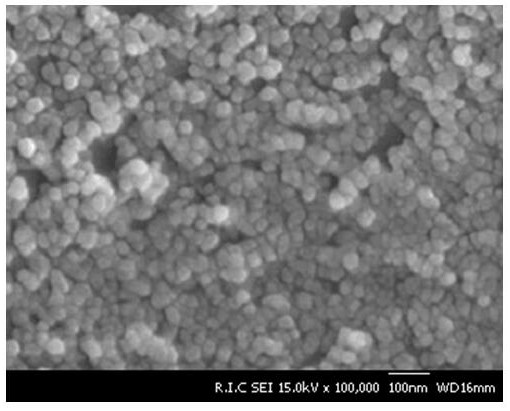

[0019] The electroplating solution provided by the present embodiment is that the size of the pre-plating palladium-nickel alloy was electroplated for 2 minutes on a copper plate plated part of 25x40mm, and the electroplating process parameters are: current density 0.5-2A / dm2, temperature 50 ℃; Based on the micro-imaging Micro-LED surface brightness detection system, the brightness of the rhodium coating is 90.1, and the rhodium coating is close to silver whiteness. A scanning electron microscope image of a rhodium coating on a copper plate is...

Embodiment 2

[0021] A kind of high-gloss decorative rhodium-plated layer electroplating solution, this electroplating solution is mixed by the component of following concentration: metal rhodium mass volume content is the rhodium sulfate solution of 10g / L, and mass volume concentration is 100g / L sulfuric acid solution, mass Volume concentration is the polyethylene glycol of 10g / L, and the mass volume concentration is the quinoline oxide of 10g / L.

[0022] The electroplating solution provided by the present embodiment is that the pre-plating palladium-nickel alloy size is 25x40mm copper plate electroplating 2 minutes, electroplating process parameter is: current density 0.5-2A / dm , temperature 50 ℃; Based on the micro-imaging Micro-LED surface brightness detection system, the brightness of the rhodium coating is 90.3, and the rhodium coating is close to silver whiteness.

Embodiment 3

[0024] A kind of high-gloss decorative rhodium-plated layer electroplating solution, this electroplating solution is mixed by the component of following concentration: metal rhodium mass volume content is the rhodium sulfate solution of 5g / L, mass volume concentration is 70g / L sulfuric acid solution, mass volume The polyethylene glycol whose volume concentration is 5g / L, and the oxidation-4-methylisoquinoline whose mass volume concentration is 5g / L.

[0025] The electroplating solution provided by the present embodiment is that the size of the pre-plating palladium-nickel alloy was electroplated for 2 minutes on a copper plate plated part of 25x40mm, and the electroplating process parameters are: current density 0.5-2A / dm2, temperature 50 ℃; Based on the detection in the micro-imaging Micro-LED surface brightness detection system, the brightness of the rhodium coating is 89.9, and the rhodium coating is close to silver whiteness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com