System and method for extracting helium from natural gas

A natural gas and helium technology, applied in the field of helium extraction, can solve the problems of helium economic value decline and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

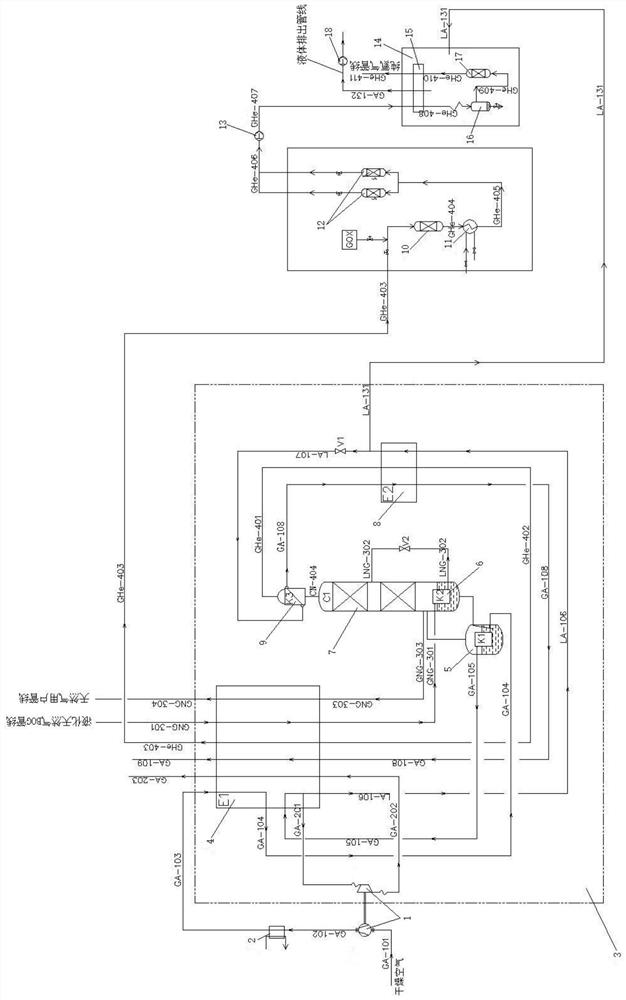

[0030] Such as figure 1 As shown, the present embodiment provides a system for extracting helium from natural gas, including an air expander 1, a cooler 2, a cold box 3, and a helium purification system; the cold box 3 includes an E1 main heat exchanger 4, a C1 refined Distillation tower 7, K1 air reboiler 5 and K2 LNG reboiler 6, E2 subcooler 8, K3 condensing evaporator 9 arranged at the bottom of C1 rectification tower 7; A furnace 10 , a cooler 11 , a helium gas purifier 12 , a compressor 13 and a Dewar vessel 14 . The Dewar vessel 14 is provided with a heat exchanger 15 , a gas-liquid separator 16 and an adsorber 17 .

[0031] The pipeline connection sequence is:

[0032] The booster end of the air expander 1, the cooler 2, and the air inlet port at the top of the E1 main heat exchanger 4 are connected sequentially, and the air outlet port in the middle of the E1 main heat exchanger 4 passes through the K1 air reboiler 5 and then exchanges heat with the E1 main heat excha...

Embodiment 2

[0040] Using the system provided in Embodiment 1, this embodiment provides a method for extracting helium from natural gas:

[0041] The air is compressed, precooled and purified (compression and precooled purification of air are conventional techniques in air separation, and will not be described in the present invention), and after removing water and carbon dioxide, the obtained pressure is 0-0.7MPaA (absolute pressure, the same below). ), the flow rate is 4800Nm 3 / h, dry air at a temperature of 10-20°C. The above-mentioned dry air enters the inlet of the booster end of the air expander 1 through the pipeline GA-101, and after being pressurized to 0.9-1MPaA, enters the cooler 2 to cool down to 40°C, and is sent to the cold box 3 through the pipeline GA-103. The air entering the cold box 3 first enters the E1 main heat exchanger 4 to cool down to -107~-109°C, is extracted from the middle part of the E1 main heat exchanger 4, and then sent to the K1 air reboiler 5, using the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com