Drying cylinder for carrying out radiation heating on soil sample

A technology for radiant heating and soil samples, which is used in the preparation of test samples, non-progressive dryers, heating devices, etc., which can solve the problems of long sample preparation cycle, low sample preparation efficiency, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

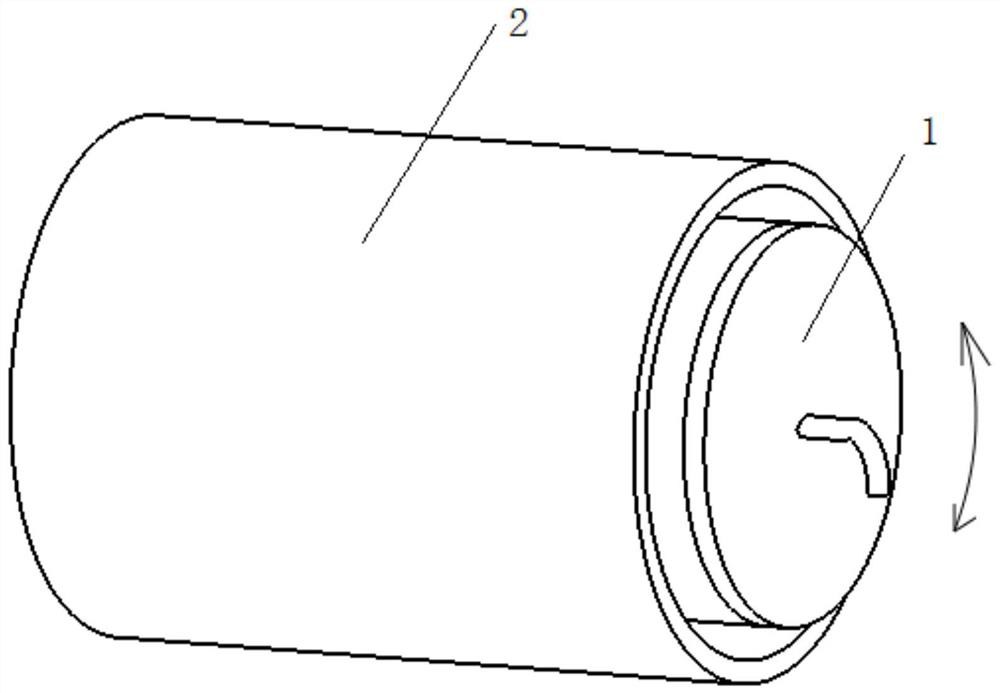

[0020] Embodiment 1: see attached figure 1 , a drying cylinder for radiative heating of soil samples. The drying cylinder 1 is a closed cylinder made of light-transmitting material. When working, the drying cylinder 1 rotates by itself and the inside is in a negative pressure state, and the drying cylinder 1 is equipped with Radiation heating device 2 heats the sample in it;

[0021] The drying cylinder 1 in this example is made of quartz or borosilicate, and the radiation heating device 2 is a heating rod capable of generating infrared light waves.

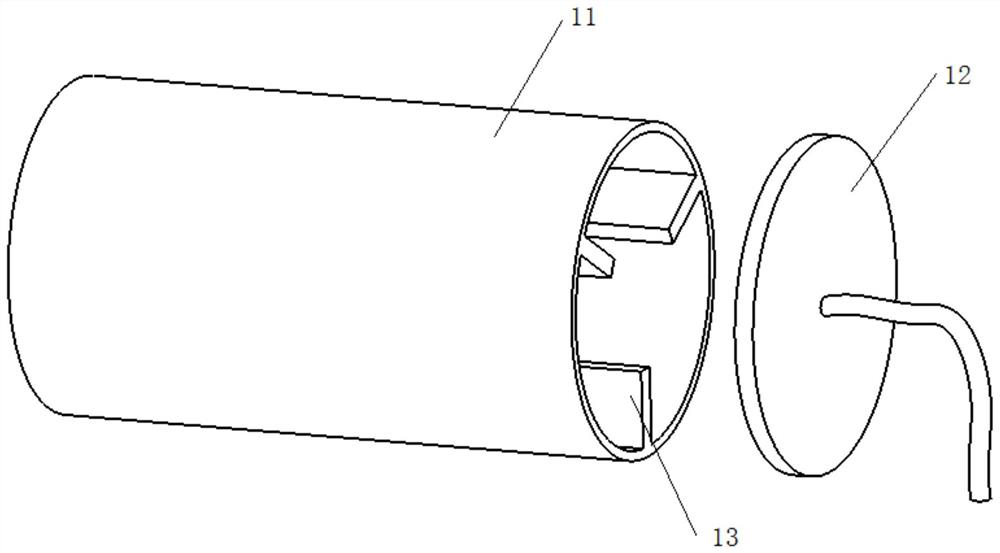

[0022] See attached figure 2 , the specific structure of the drying cylinder 4 includes: a cylinder body 11 and at least one bung 12; 12 is provided with a suction hole for communicating with the suction device. The self-rotation of the drying drum 1 can be realized through the cooperation of idler rollers and transmission sprocket wheels or belt transmission, and can also be realized by arranging other methods such as rotati...

Embodiment 2

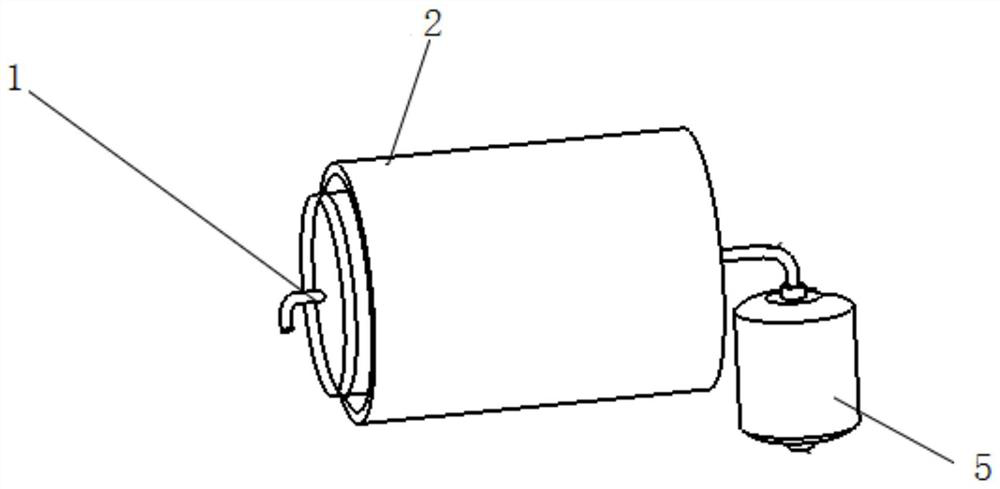

[0025] Embodiment 2: see attached image 3 , on the basis of Example 1, further, in order to ensure that the original components of the soil sample in the drying cylinder 1 are not lost during the sample preparation process, the connecting pipeline between the air extraction hole and the air extraction device is connected in series and filled with adsorption material The adsorption device 5; activated carbon or modified composite material is housed in the adsorption device 5, which is used to adsorb volatile organic compounds in the soil sample, or volatile inorganic elements such as mercury and arsenic, and then the adsorbed The material was backfilled into the soil sample.

Embodiment 3

[0026] Embodiment 3: see attached Figure 4 , in order to realize the rise and fall of the drying cylinder 1, on the basis of embodiment 1 or 2, the drying cylinder 1 and the radiation heating device 2 are installed on the lifting plate 3; in this example, the lifting plate 3 uses slideways and push rods way to achieve rise and fall;

[0027] Further, for the convenience of taking and placing soil samples in the drying cylinder 1, bearing seat assemblies 4 are provided on the left and right sides of the lifting plate 3, and the bearing seat assemblies 4 are connected with the peripheral rotating mechanism. , through the rotating mechanism, the drying cylinder 1 and the radiation heating device 2 are raised or lowered at a certain angle as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com