Elution method for reserved plutonium in PUREX process dirty solvent

An elution method and solvent technology, applied in the field of radioactive waste treatment, can solve the problems of increased degradation products, failure to return to process reuse, and unsatisfactory results, achieving good application prospects and good elution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

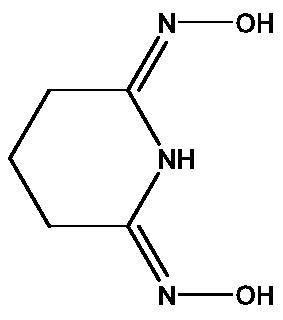

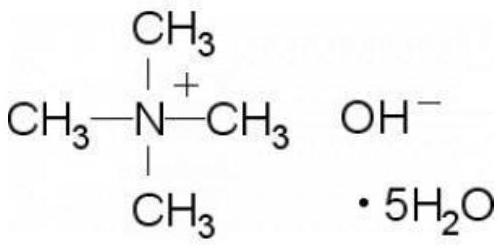

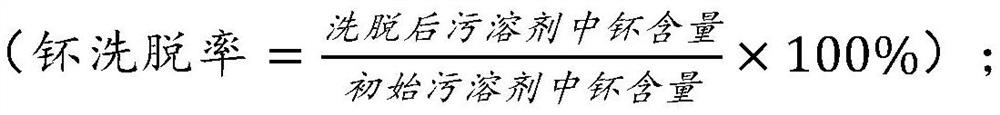

[0025] The 2BW material liquid obtained from a thermal experiment in the PUREX process technology research of China Institute of Atomic Energy is used as the processing object. The feed solution is the polluted solvent with excessive plutonium content obtained from the plutonium purification cycle. During the test, dilute acid solution, tetravalent uranium solution, N,N-dimethylhydroxylamine solution and sodium carbonate solution were used to elute plutonium. Its main chemical composition is: 30% (volume percentage) tributyl phosphate (TBP) and 70% (volume percentage) hydrogenated kerosene, in which plutonium content is 0.057g / L, nitric acid content is 0.03mol / L, dibutyl phosphate The content of ester acid (DBP) is 0.90×10 -3 mol / L, monobutyl phosphate (MBP) content is 2.30×10 -4 mol / L, the contents of other degradation products and metal ions were not determined. Before this experiment, the material solution had been placed for more than 4 years, and its appearance was a ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com