Silicon dioxide adsorption agent modified by zero-valent iron/chitosan and preparation method and application thereof

A technology of silica and chitosan, which is applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of environmental secondary pollution, etc., and achieve large adsorption capacity, short treatment cycle and simple operation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

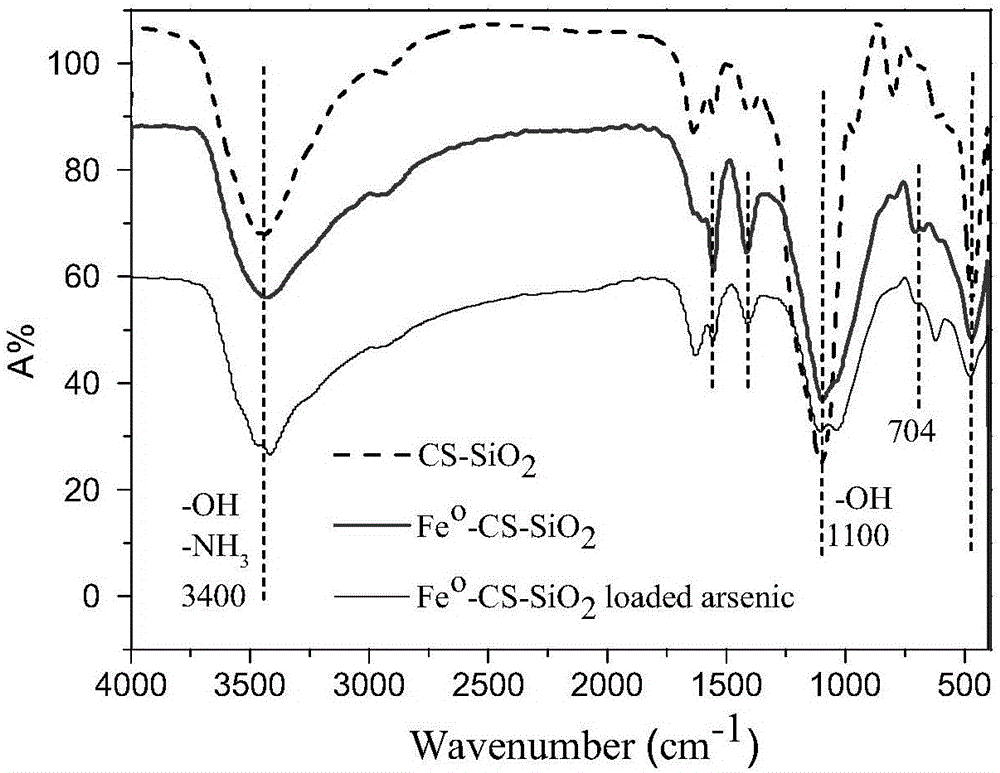

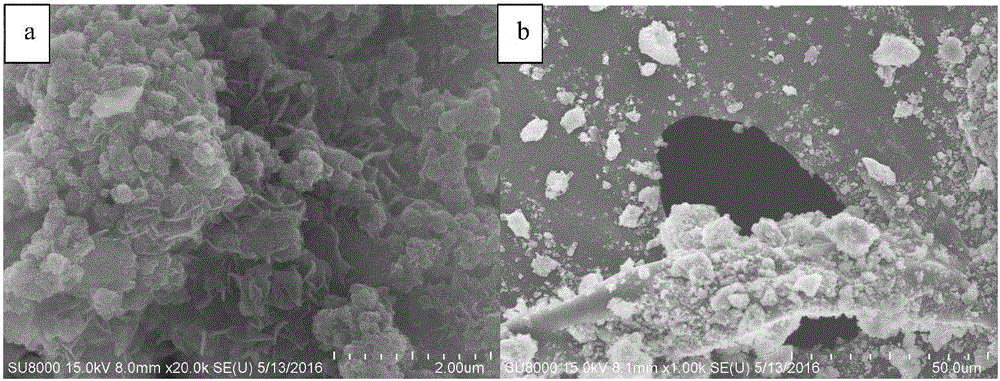

[0027] Example 1 A zero-valent iron / chitosan modified silica adsorbent (Fe 0 -CS-SiO 2 )

[0028] (1) The preparation method is as follows

[0029] Dissolve 2g of chitosan into 100mL of acetic acid solution with a concentration of 2% (v / v), then add 30mL TEOS to the above solution, stir magnetically for 30min at room temperature, then add 200mL of TEOS with a concentration of 3% (v / v) ammonia water, stirred at room temperature for 24 h, filtered the resulting suspension, discarded the filtrate, and washed the residue with distilled water until it reached neutrality to obtain the intermediate product CS-SiO 2 .

[0030] 0.5g CS-SiO 2 Add to a 250mL three-neck flask, add 10mL of water, under N 2 Under protection, it was stirred under magnetic force at 80°C for 15 minutes, and then weighed 4.5g FeSO 4 ·7H 2 O (mass ratio 1:9) was added to the above solution, and after stirring for 30 minutes, 50 mL, 0.5 mol L -1 NaBH 4 , and reacted at 80°C for 4h, then filtered and drie...

Embodiment 2

[0035] Example 2 A zero-valent iron / chitosan modified silica adsorbent (Fe 0 -CS-SiO 2 )

[0036] Method is the same as embodiment 1, selects FeSO 4 ·7H 2 O and CS-SiO 2 The mass ratios are 1:7, 1:8, 1:9, 1:10, 1:11, respectively. As shown in Table 1, the adsorption rates of the five synthesized adsorbents for As(III) under the condition of pH=4 were 89.1%, 100%, 98.9%, 100%, and 99.6%, respectively. It can be seen that FeSO 4 ·7H 2 O and CS-SiO 2 When the mass ratio is in the range of 1:8-1:11, the adsorption performance of As(III) is high.

[0037] Table 1 Different FeSO 4 ·7H 2 O and CS-SiO 2 Effect of ratio on the adsorption effect of As(III)

[0038]

Embodiment 3

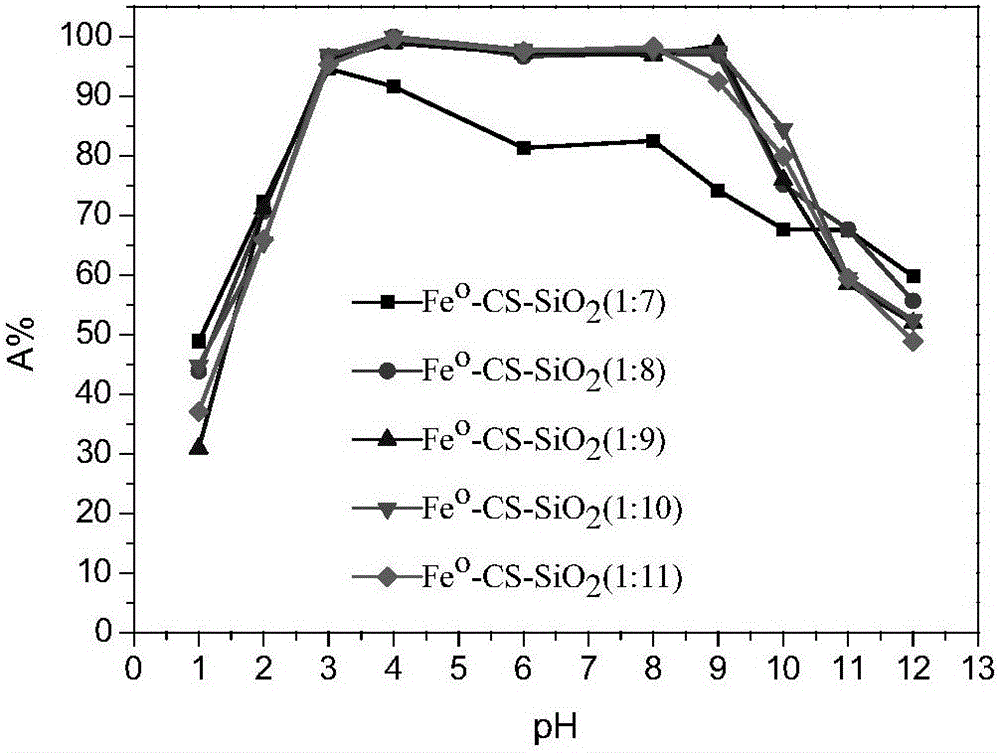

[0039] Example 3 Fe under different solution acidity conditions 0 -CS-SiO 2 Adsorption performance of adsorbents for As(III)

[0040] 10mg Fe 0 -CS-SiO 2 The adsorbent is mixed with 10mL of 20ppm As(III) solution with different pH (pH=1, 2, 3, 4, 6, 8, 9, 10, 11, 12); ℃ shaking for 24h.

[0041] The adsorption rate was measured as image 3 ,Depend on image 3 Visible, Fe 0 -CS-SiO 2 When the adsorbent is at pH4-pH9, the maximum adsorption rate of As(III) is greater than 98%. It can be seen that under the condition of pH=4~9, Fe 0 -CS-SiO 2 The adsorbent extracts As(III) from the solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com