Self-throughput oil absorption filter plate for oil-containing waste gas

A technology for oil filtration and exhaust gas, applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of easy clogging of filtration equipment, damage, poor oil adsorption effect, etc., to improve the comprehensiveness of treatment and efficient absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

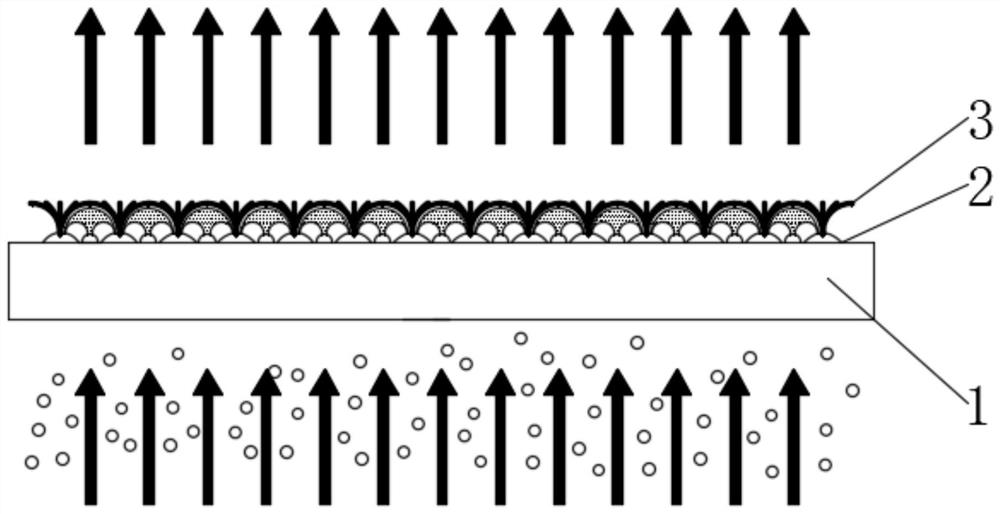

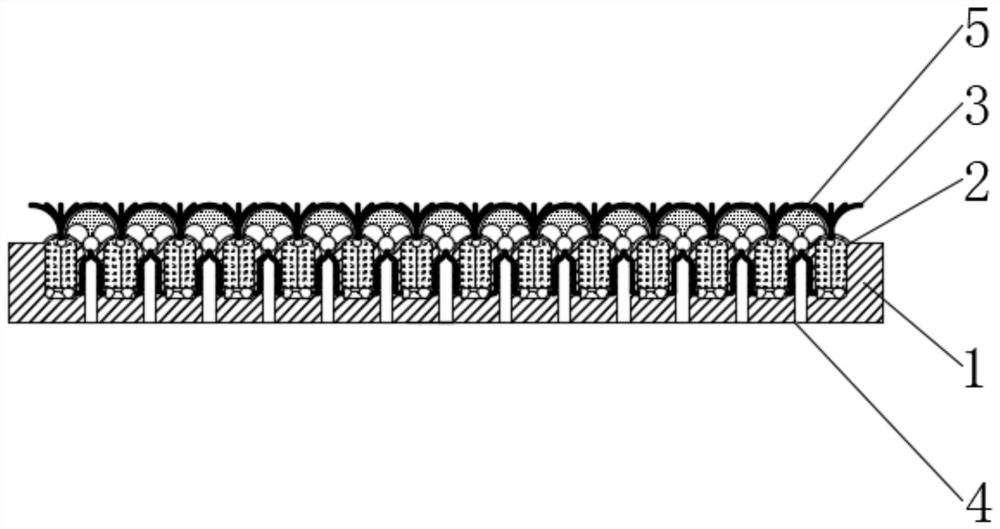

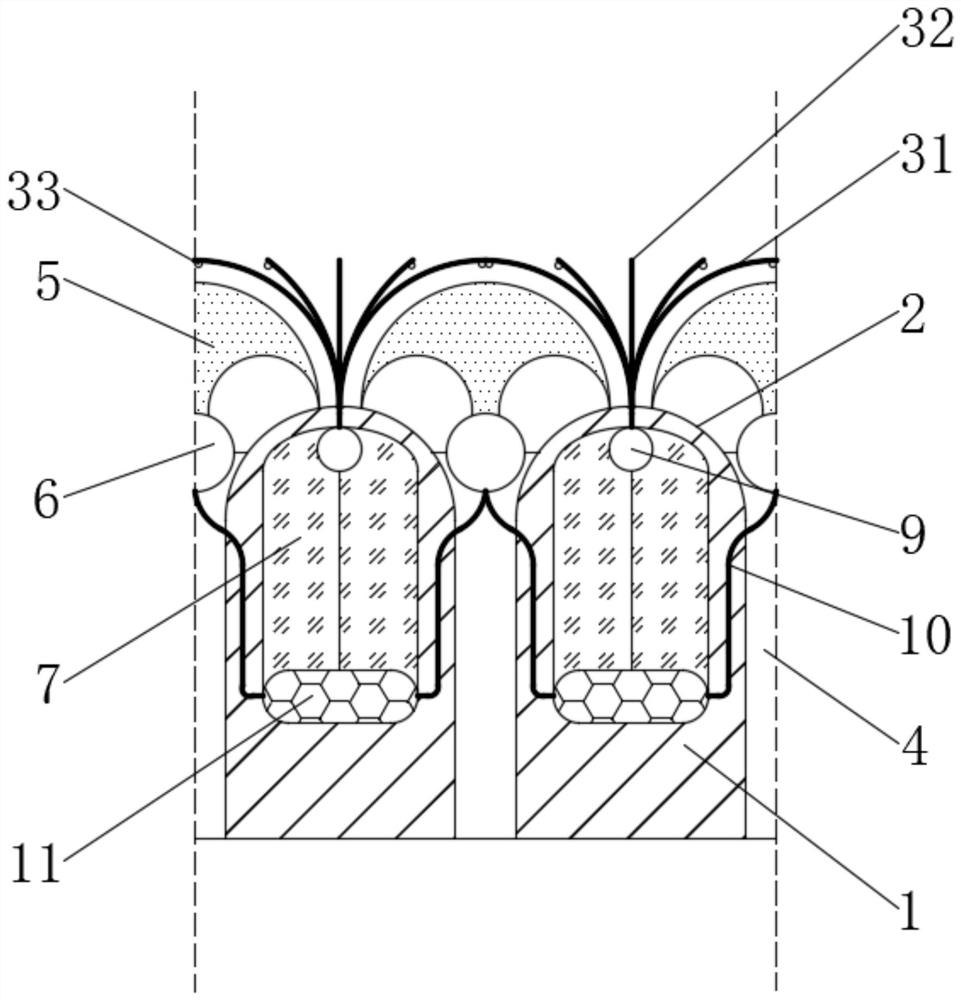

[0043] see Figure 1-3 , a self-throughput type oil-absorbing filter plate for oily waste gas, including a filter plate body 1, a plurality of uniformly distributed spherical throughput units 2 are connected to the upper end of the filter plate body 1, and the spherical throughput units 2 and the filter plate body 1 are integrally formed , the filter plate body 1 is provided with a plurality of evenly distributed air guide holes 4, and the air guide holes 4 and the spherical throughput units 2 are alternately distributed, and a pair of adjacent spherical throughput units 2 are fixedly connected with a shunt umbrella cap 5, The lower end of the shunt umbrella cap 5 is fixedly connected with the flow control airbag 6, and the flow control airbag 6 extends into the air guide hole 4, the upper end of the spherical throughput unit 2 is inlaid with the oil suction flap 3, and the lower end of the oil suction flap 3 is fixedly connected with the spherical throughput unit. The oil sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com