Garbage treatment device for new energy production and using method thereof

A garbage disposal device and new energy technology, applied in the direction of grain treatment, separation methods, chemical instruments and methods, etc., can solve the problems of waste of resources, increase of labor intensity, bad smell, etc., and achieve good crushing effect and structure The design is reasonable and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

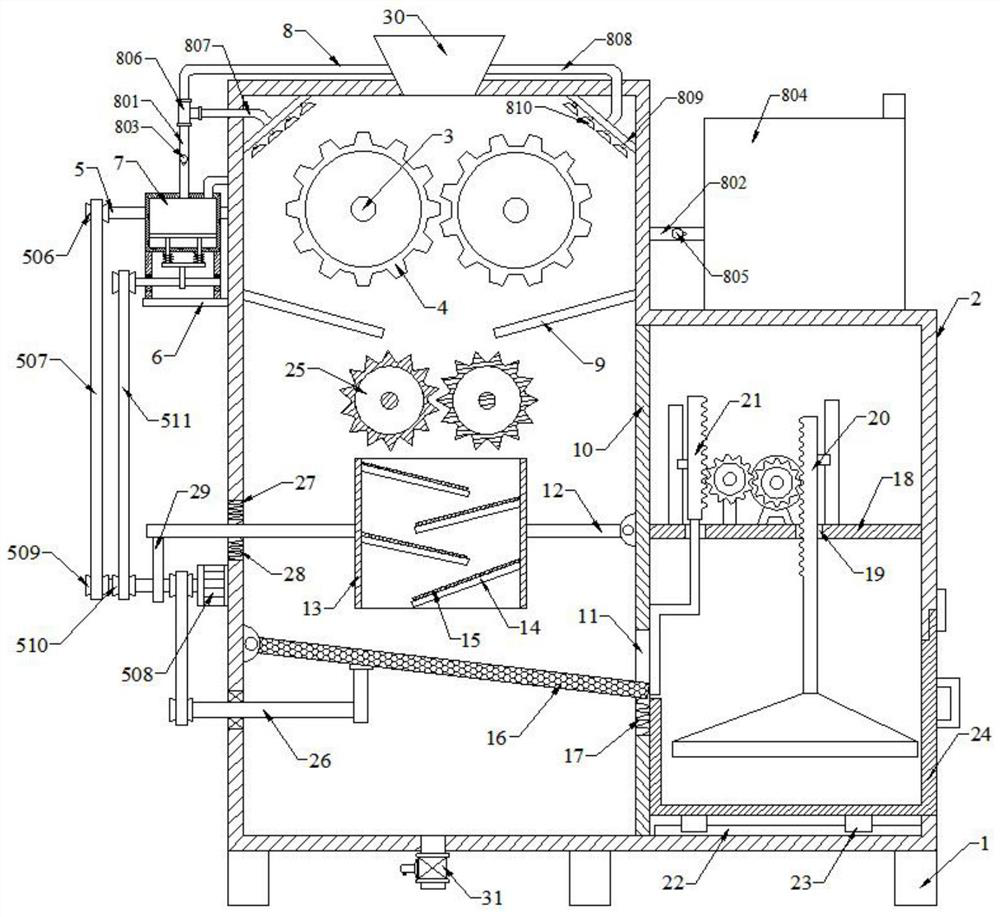

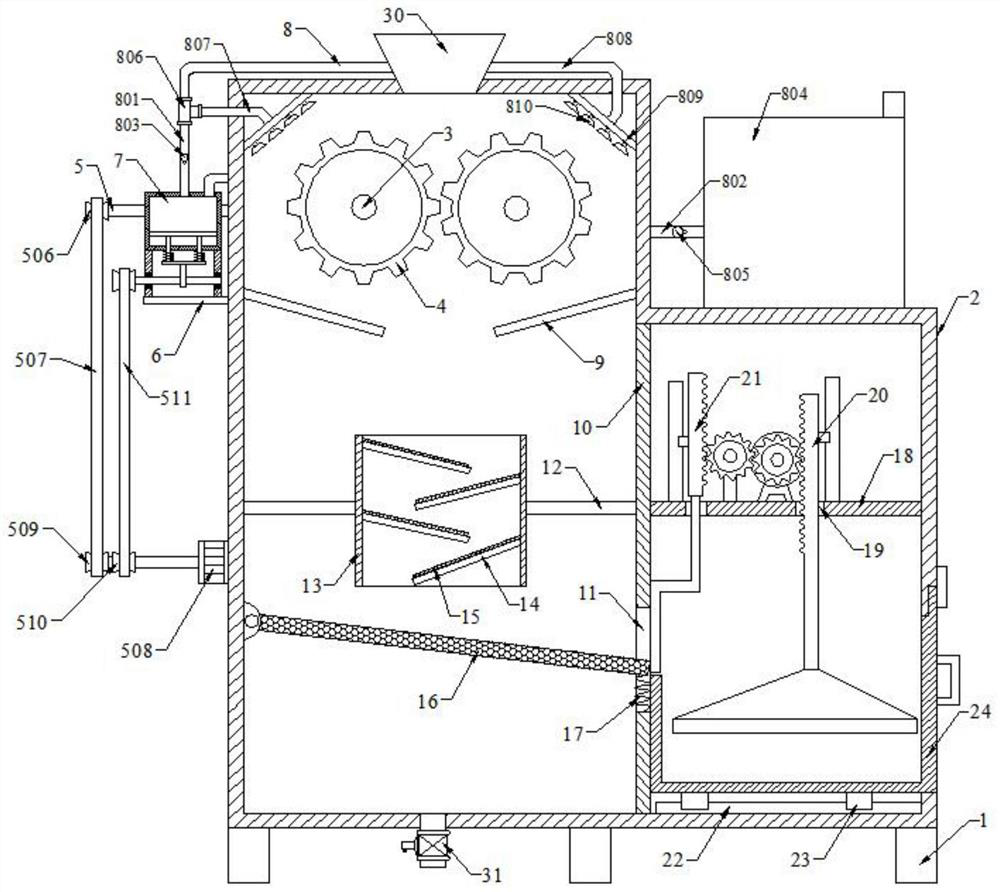

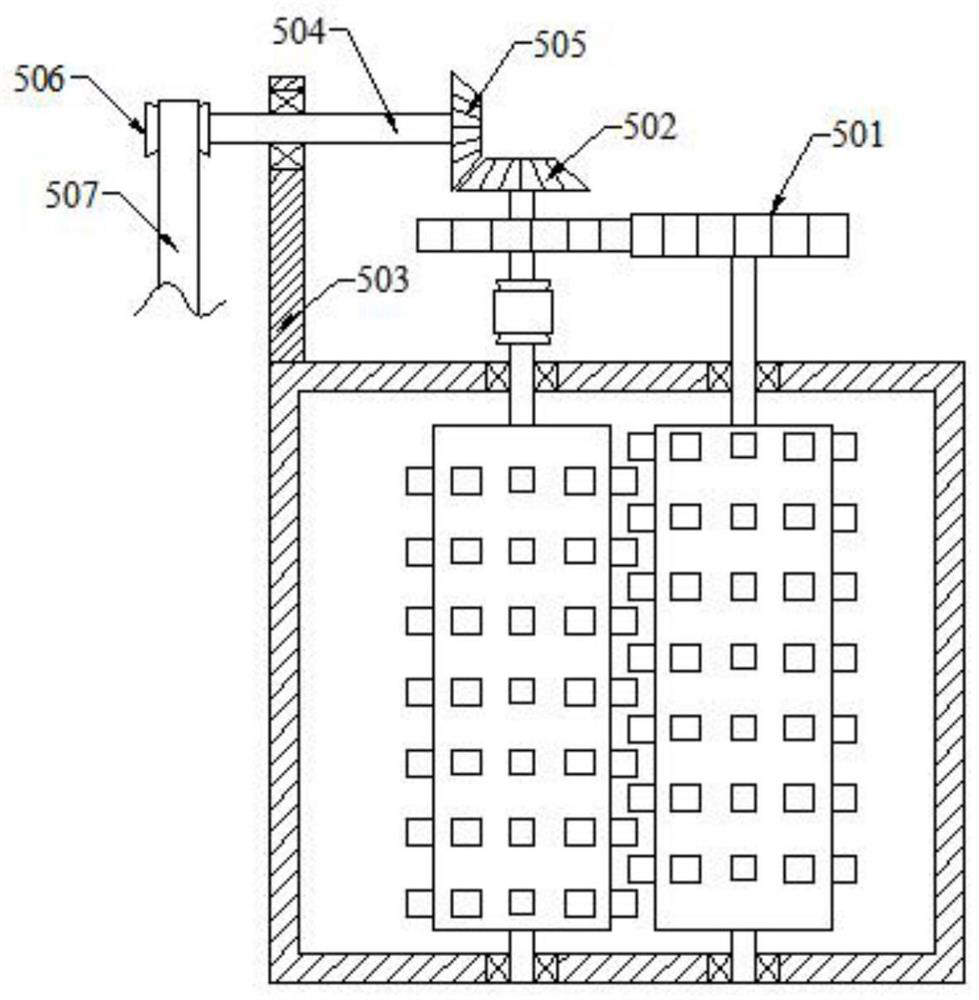

[0047] Please refer to the accompanying drawings, the present embodiment is a waste treatment device for new energy production, including a support 1, a treatment box 2 is arranged on the upper end of the support 1, and two first A rotating shaft 3, the crushing roller 4 is installed on the first rotating shaft 3, the transmission assembly 5 is connected to the rear end of the first rotating shaft 3, the support plate 6 is fixedly connected to the left wall of the processing box 2, and the water pressure assembly 7 is arranged on the upper end of the support plate 6 , the pressurized water assembly 7 is connected with a spray assembly 8, the left and right inner walls of the processing box 2 are symmetrically fixed with a material guide plate 9, the middle part of the processing box 2 is vertically provided with a partition 10, and the lower side of the partition 10 is provided with a feed chute 11, The left wall of the inner cavity of the processing box 2 and the left end of t...

Embodiment 2

[0066] Please refer to the accompanying drawings, on the basis of Embodiment 1, it also includes a crushing assembly 25, the crushing assembly 25 includes two third rotating shafts 2501, the third rotating shaft 2501 is rotatably connected to the front and rear side walls of the processing box 2, and the third rotating shaft 2501 The crushing roller 2502 is installed on the top, the rear end of the third rotating shaft 2501 on both sides is provided with the fourth spur gear 2503, the meshing transmission between the fourth spur gears 2503 on both sides, the third rotating shaft 2501 on the left side is provided with the fifth belt Pulley 2504, the third belt 2505 is installed on the fifth pulley 2504, the sixth pulley 2506 is arranged on the rear side of the first rotating shaft 3 on the left side, the sixth pulley 2506 is connected with the fifth pulley 2504 through the third belt 2505 .

[0067] Specifically, step S7 is also included: when the garbage crushed by the two cru...

Embodiment 3

[0069] Please refer to the accompanying drawings, on the basis of Embodiment 1, a vibration assembly 26 is also included, and the vibration assembly 26 includes a fourth rotating shaft 2601. The second cam 2602, the left end of the fourth rotating shaft 2601 is provided with the seventh pulley 2603, the fourth belt 2604 is installed on the seventh pulley 2603, the output end of the first servo motor 507 is provided with the eighth pulley 2605, the eighth pulley 2605 is in drive connection with the seventh pulley 2603 through the fourth belt 2604, and the left end of the filter plate 16 is hinged to the left wall of the inner chamber of the processing box 2.

[0070] Specifically, step S8 is also included: According to Embodiment 1, the first servo motor 507 rotates and drives the eighth pulley 2605 to rotate, and the eighth pulley 2605 drives the seventh pulley 2603 and the fourth rotating shaft 2601 through the fourth belt 2604 Rotate, thereby driving the second cam 2602 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com