Ignition powder containing boron-magnesium sintered powder

A technology of sintering powder and ignition powder, applied in ignition agent, attack equipment and other directions, can solve problems such as reducing combustion temperature, and achieve the effect of fast gas production rate, broad application prospect and high flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

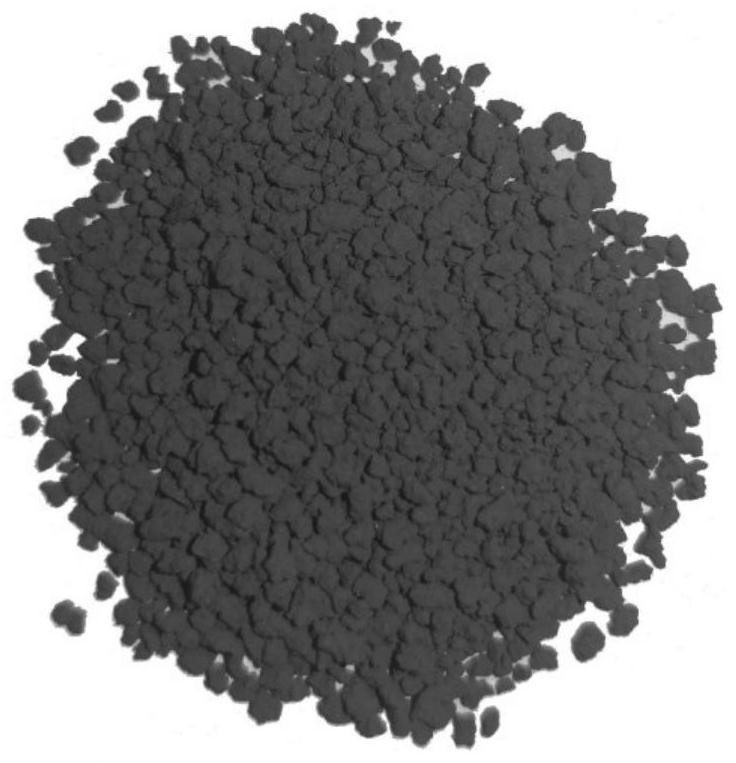

Image

Examples

Embodiment 1

[0048] A kind of ignition powder containing boron magnesium sintered powder, described ignition powder is to make by following preparation method:

[0049] (1) Pre-processing:

[0050] The fluororubber is dissolved in ethyl acetate to obtain a fluororubber solution, and the ratio of the amount of fluororubber dissolved in ethyl acetate is 1g:5mL;

[0051] Will KNO 3 Put it in a blast drying oven, dry at 40°C for 24 hours, take it out and grind it, pass through a 60-mesh sieve, and take the under-sieve, which is the pretreated KNO 3 .

[0052] Dry mixing: take boron-magnesium sintered powder with a mass ratio of magnesium to boron of 1:4 and pretreated KNO 3 Perform mechanical stirring and mixing, the boron-magnesium sintered powder and potassium nitrate pass through a 60-mesh sieve respectively, and repeat the process 5 times to obtain a mixed powder. The mass ratio of the mixed powder is: potassium nitrate: 60%, boron magnesium sintered powder 40%.

[0053] (3) Wet mixin...

Embodiment 2

[0062] A kind of ignition powder containing boron magnesium sintered powder, described ignition powder is to make by following preparation method:

[0063] (1) Pre-processing:

[0064] Dissolving fluororubber in a mixed solvent of acetone and ethyl acetate to obtain a fluororubber solution, the ratio of the amount of fluororubber dissolved in ethyl acetate is 1g:20mL;

[0065] Will KNO 3 Dry at 50°C for 16 hours, take out and grind, pass through a 60-mesh sieve, and take the under-sieve, which is the pretreated KNO 3 .

[0066] (2) Dry mixing: take boron-magnesium sintered powder with a mass ratio of magnesium to boron of 1:2 and pretreated KNO 3 Perform mechanical stirring and mixing, the boron-magnesium sintered powder and potassium nitrate pass through a 60-mesh sieve respectively, and repeat the process 5 times to obtain a mixed powder. The mass ratio of the mixed powder is: potassium nitrate: 75%, boron magnesium sintered powder 25%.

[0067] (3) Wet mixing: add 3% f...

Embodiment 3

[0076] A kind of ignition powder containing boron magnesium sintered powder, described ignition powder is to make by following preparation method:

[0077] (1) Pre-processing:

[0078] The fluororubber is dissolved in a mixed solvent of acetone and ethanol to obtain a fluororubber solution, and the ratio of the amount of fluororubber dissolved in ethyl acetate is 1g:10mL;

[0079] Will KNO 3 Dry it at 60°C for 8 hours, take it out and grind it, pass through a 60-mesh sieve, and take the under-sieve, which is the pretreated KNO 3 .

[0080] (2) Dry mixing: take boron-magnesium sintered powder with a mass ratio of magnesium to boron of 1:3 and pretreated KNO 3 Perform mechanical stirring and mixing, the boron-magnesium sintered powder and potassium nitrate pass through a 60-mesh sieve respectively, and repeat the process 5 times to obtain a mixed powder. The mass ratio of the mixed powder is: potassium nitrate: 70%, boron magnesium sintered powder 30%.

[0081] (3) Wet mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com