Phenylboronic acid polymer and preparation method and application thereof in modified xanthan gum

A technology of polymer and phenylboronic acid, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of limited temperature resistance, high production cost and large dosage of xanthan gum, and achieve enhanced viscosity and good anti-aging Effects of degradability and strong anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

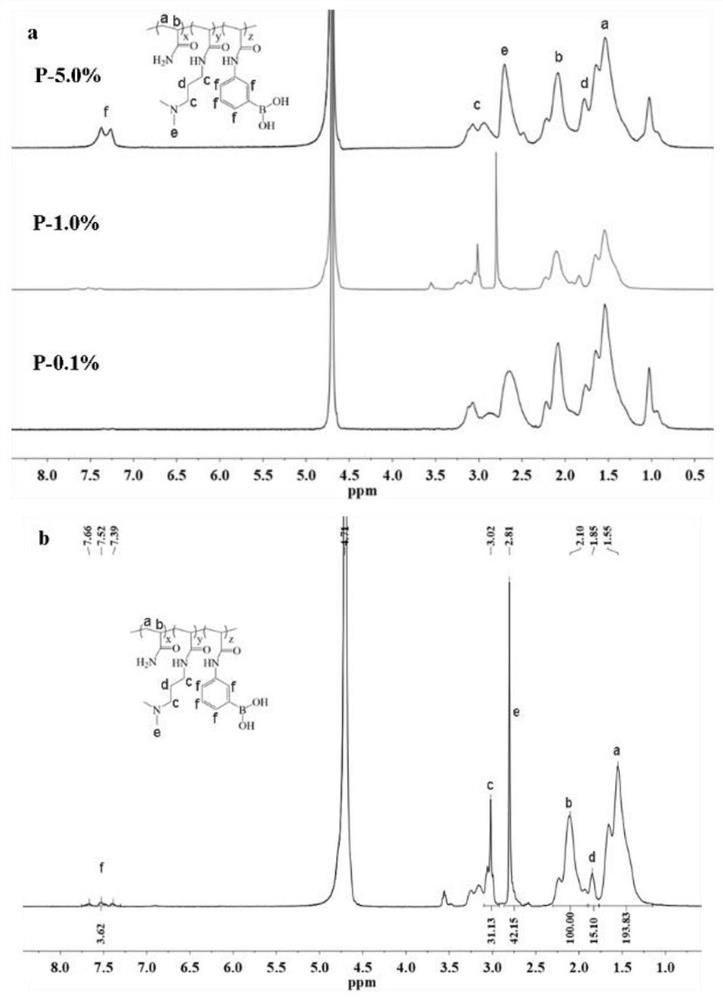

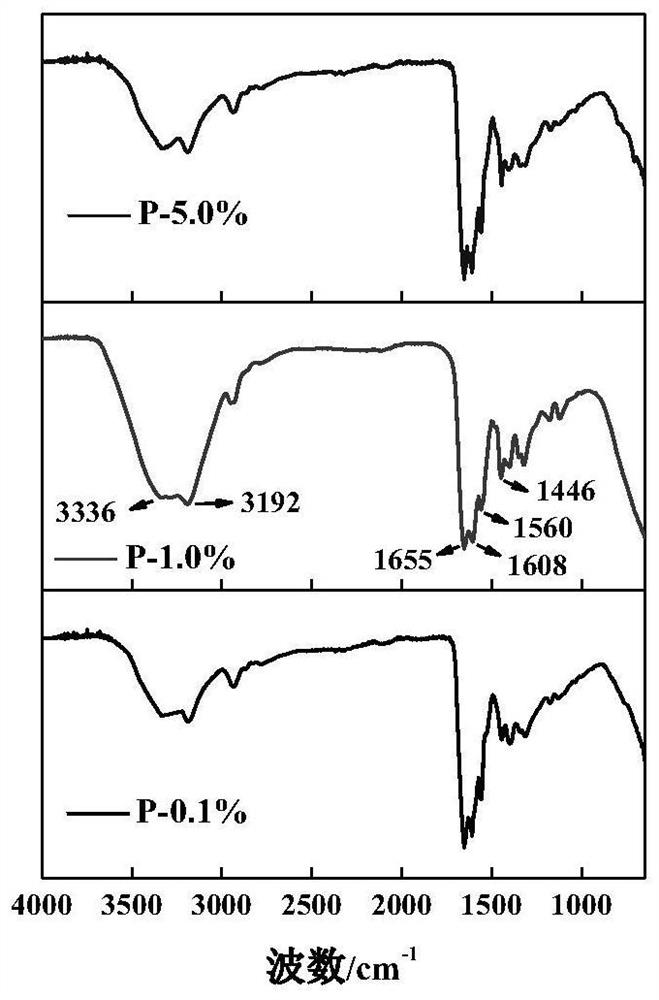

[0038] The synthesis of embodiment 1, terpolymer P (AM-co-DMAPAM-co-AMBB)

[0039] The synthetic route is as follows:

[0040]

[0041] N-(3-dimethylaminopropyl) acrylamide contains a polymerization inhibitor p-methoxyphenol (MEHQ), and the monomer needs to be purified before polymerization. The treatment method is: monomer N-(3- Dimethylaminopropyl) acrylamide is separated and purified by basic alumina (100-200 mesh) chromatography column (column height 8cm), rinsed with anhydrous ether, and the eluate is dried in a vacuum oven after rotary evaporation After 24 hours, the monomer changed from yellow to colorless before removing the inhibitor.

[0042] The polymerization steps are as follows: weigh acrylamide (AM), N-(3-dimethylaminopropyl)acrylamide (DMAPAM), and 3-acrylamide phenylboronic acid (AMBB) according to the ratio in Table 1, and dissolve them in deionized water (the total mass fraction of three kinds of monomers is 10%), vacuumize and lead to N 2 Deoxygenate ...

Embodiment 2

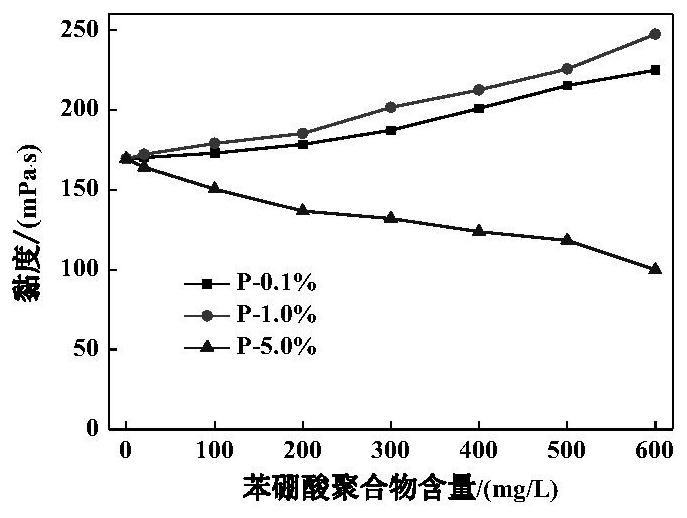

[0065] Embodiment 2, polymer P (AM-co-DMAPAM-co-AMBB) to the modification research of xanthan gum

[0066] Dissolve xanthan gum with deionized water under stirring at room temperature to prepare xanthan gum mother liquor with a mass concentration of 2.5g / L, mix and dilute it with 20g / L phenylboronic acid polymer mother liquor in proportion to the target compounding concentration , stirred at room temperature to mix well. The concentration of xanthan gum in the compound solution is 2.0g / L, and the concentration of phenylboronic acid polymer is 0, 20, 100, 200, 300, 400, 500, 600mg / L respectively. According to the standard Q / HS 2032-2018 [21] The viscosity of the compound solution was measured to evaluate the viscosity-increasing performance of the compound system.

[0067] 1. Viscosity of compound system

[0068] The concentration of xanthan gum is 2.0g / L. With the change of the amount of phenylboronic acid polymer P(AM-co-DMAPAM-co-AMBB), the viscosity of the compound syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com