Novel nano hybrid flame-retardant polyurethane elastomer and preparation method thereof

A polyurethane elastomer and nano-hybrid technology, which is applied in the field of novel nano-hybrid flame-retardant polyurethane elastomer and its preparation, can solve the problems of poor dispersion, limited improvement of polymer material performance, and weak interaction, etc., to achieve improved Load capacity, overcoming harmful substances and smoke, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

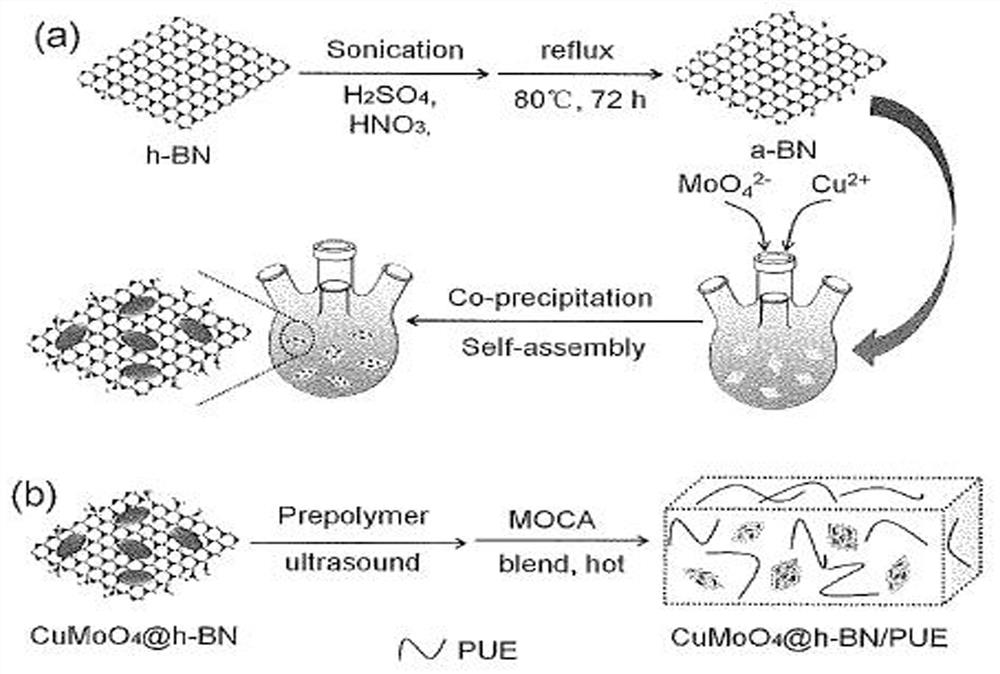

[0029] Preparation of nano-hybrid flame retardant:

[0030] (1) Take concentrated sulfuric acid and concentrated nitric acid solution and mix them at a volume ratio of 1:3 to obtain a concentrated acid solution. Take hexagonal boron nitride powder and place it in the concentrated acid solution, and ultrasonicate for 6 hours to obtain a light yellow viscous liquid;

[0031] (2) Reflux the light yellow viscous liquid oil bath obtained in step (1) at 80°C for 72 hours, wash, centrifuge, and freeze-dry to obtain surface-functionalized h-BN;

[0032] (3) The surface-functionalized h-BN obtained in step (2) was placed in deionized water and ultrasonically stirred for 30 minutes to obtain h-BN suspension;

[0033] (4) Add 0.85g of CuCl 2 Put into deionized water, stir until completely dissolved, add dropwise to step (3) to obtain h-BN suspension, stir ultrasonically for 1 hour, and then react under 60°C oil bath conditions for 12 hours to obtain a mixed solution;

[0034] (5) Put 0...

Embodiment 2

[0036] 44.4g of polyester polyol, 7.83g of TDI, 4.6g of MOCA, 1g of the novel nano-hybrid flame retardant prepared in Example 1, the novel nano-hybrid flame-retardant polyurethane elastomer was prepared according to the following method, and the specific preparation steps were:

[0037] (1) Dehydrate the polyester polyol in a reaction kettle at 110°C for 2 hours, then cool to 70°C, add TDI, heat up to 75°C, stir for 2 hours, and vacuum dehydrate at 80°C for 30 minutes to obtain a prepolymer;

[0038] (2) The nano-hybrid CuMoO 4 @h-BN is uniformly dispersed in an appropriate amount of acetone solution under ultrasonic conditions, then poured into the prepolymer, and stirred for 5 minutes under ultrasonic conditions at 75°C to form a uniform mixture;

[0039] (3) Add MOCA to the mixture, stir vigorously, pour into a mold, heat at 80°C for 6h, and heat at 120°C for 2h to obtain CuMoO 4 @h-BN / PUE is a new type of nano-hybrid flame-retardant polyurethane elastomer.

Embodiment 3

[0041] 45g of polyester polyol, 7.9g of TDI, 4.7g of MOCA, 0.5g of the novel nano-hybrid flame retardant prepared in Example 1, and prepare the novel nano-hybrid flame-retardant polyurethane elastomer according to the following method, the specific preparation steps are:

[0042] (1) Dehydrate the polyester polyol in a reaction kettle at 105°C for 1.7 hours, then cool to 67°C, add TDI, heat up to 72°C, stir for 2.3 hours, and vacuum dehydrate at 75°C for 45 minutes to obtain a prepolymer;

[0043] (2) The nano-hybrid CuMoO 4 @h-BN is uniformly dispersed in an appropriate amount of acetone solution under ultrasonic conditions, then poured into the prepolymer, and stirred for 5 minutes under ultrasonic conditions at 70°C to form a uniform mixture;

[0044] (3) Add MOCA to the mixture, stir vigorously, pour into a mold, heat at 75°C for 7h, and heat at 130°C for 2.5h to obtain CuMoO 4 @h-BN / PUE is a new type of nano-hybrid flame-retardant polyurethane elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com