Light conversion film capable of promoting plant growth and preparation method thereof

A technology that promotes plant growth and light conversion. It is applied in the field of agricultural light conversion materials. It can solve the problems that plants cannot provide strong red light, the energy utilization rate of light sources is not high, and the price of LED chips is high. It achieves wide coverage, low cost, and avoids Effects of yellowing and disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

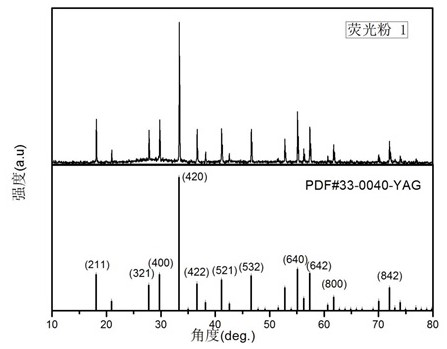

[0035] press Y 1.97 BaAl 3.95 SiO 12 : 0.03Ce, stoichiometric ratio shown in 0.05Cr chemical formula, weigh 0.2224g of Y 2 o 3 , 0.1973g of BaCO 3 , 0.2015g of Al 2 o 3 , 0.0601g of SiO2 、0.0052g的CeO 2 和0.0038g的Cr 2 o 3 ,将称取的各原料充分研磨混合均匀后放入氧化铝坩埚,置于管式炉中,在温度为1450℃(体积百分比5%H 2 和95%N 2 气氛)下煅烧4小时(管式炉预热温度为200-300℃,原料放入管式炉之后的升温速度为5℃ / min),随炉冷却至室温,得煅烧物;研磨所得煅烧物,制得荧光粉1。荧光粉1的XRD图谱如 figure 1 所示,图中各峰峰形、峰位与PDF卡片一一对应,证明制得的粉末的物相为单相。

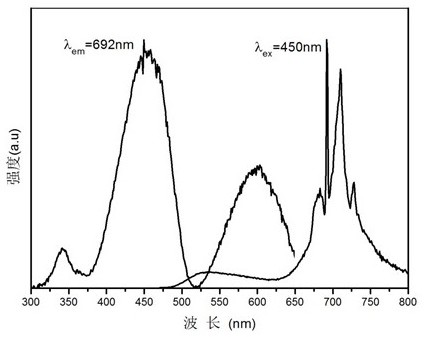

[0036] 随后测量该样品的激发和发射光谱,见 figure 2 ,激发光谱显示存在三个宽峰,激发峰峰值分别位于342nm、450nm和600nm,发射光谱显示了多个发射峰,其中在692nm处存在一个窄峰且强度最高。通过光谱图我们可以发现,Y 1.97 BaAl 3.95 Sio 12 :0.03Ce,0.05Cr可被波长范围在310~380nm、380~520nm和520~660nm的光激发,有着很广的激发区域,而且试样在紫外光310~380nm区域有吸收,从而避免了太阳光对膜造成的黄变和崩解;发光光谱中该试样发出波长约为683nm、692nm、710nm、728nm的红光。

Embodiment 2

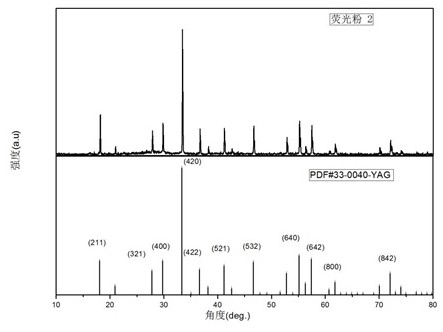

[0038] press Y 1.97 BaAl 3.95 SiO 12 : 0.03Ce, stoichiometric ratio shown in 0.05Cr chemical formula, weigh 0.2224g of Y 2 o 3 , 0.1973g of BaCO 3 , 0.2015g of Al 2 o 3 , 0.0601g of SiO 2 、0.0052g的CeO 2 和0.0038g的Cr 2 o 3 ,再加4wt%的AlF 3 为助熔剂,将称取的各原料充分研磨混合均匀后放入氧化铝坩埚,置于管式炉中,在温度为1450℃(5%H 2 和95%N 2 气氛)下煅烧4小时(管式炉预热温度为200-300℃,原料放入管式炉之后的升温速度为5℃ / min),随炉冷却至室温,得煅烧物;研磨所得煅烧物,制得荧光粉2。荧光粉2的XRD图谱(如 image 3 所示),图中各峰峰形、峰位与PDF卡片一一对应,证明制得的粉末的物相为单相,从荧光粉2的发射光谱与荧光粉1的发射光谱的对比(如 Figure 4 ),我们可以看出荧光粉的发光强度相对于荧光粉1提高了46.4%。

Embodiment 3

[0040] 将胶与荧光粉按照4:1的比例制做膜。具体为:称量A、B胶各0.6g,加入实施例2中制得的0.3g的荧光粉2,随之将其放入真空脱泡机中进行抽真空搅拌(搅拌时间为2min30s)。将搅拌均匀后的混合物放入烘箱内烘干。6h后将烘干好的膜1取出,测量其在450nm处激发下的发射光谱,如 Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com