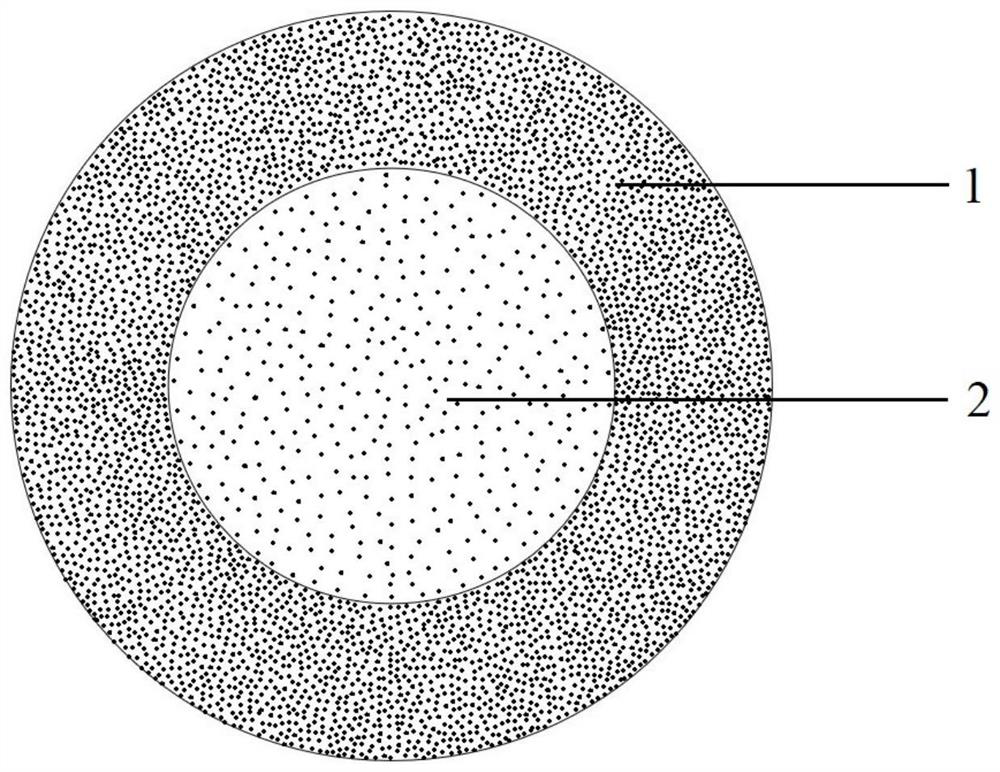

Polyphenylene sulfide composite melt-spun fiber with composite antioxidant dispersed in gradient manner and preparation method thereof

A composite antioxidant, polyphenylene sulfide technology, applied in the direction of conjugated synthetic polymer rayon, fiber processing, fiber chemical characteristics, etc., can solve the shortened service life of PPS fiber and fiber products, PPS fiber defects, C-S Bonds are easily oxidized and broken, so as to achieve the effect of anti-oxidation performance and overall performance, improve anti-oxidation effect, and excellent thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of polyphenylene sulfide composite melt-spun fiber with gradient dispersion of composite antioxidant, comprising the following steps:

[0047] 1) Preparation of composite antioxidant by chemical grafting method: First, dissolve 10g graphene oxide in 500mL ethanol deionized water mixed solution, wherein the volume ratio of ethanol to deionized water is 3:1, and mechanically stir at 60°C 2h, then ultrasonically dispersed at room temperature for 2h to obtain a graphene oxide dispersion; weigh 30g of antioxidant GA-80 and pour it into 200mL of ethanol to obtain an ethanol solution mill of a high-temperature resistant antioxidant, and grind the high-temperature resistant antioxidant The ethanol solution of the antioxidant and the graphene oxide dispersion were heated to 50°C respectively, and the ethanol solution of the high-temperature resistant antioxidant was added dropwise to the graphene oxide dispersion within 1 hour at 50°C, and magnetically stirre...

Embodiment 2

[0053] A preparation method of polyphenylene sulfide composite melt-spun fiber with gradient dispersion of composite antioxidant, comprising the following steps:

[0054] 1) Preparation of composite antioxidant by chemical grafting method: First, dissolve 10g graphene oxide in 500mL ethanol deionized water mixed solution, wherein the volume ratio of ethanol to deionized water is 3:1, and mechanically stir at 60°C 2h, then ultrasonically dispersed at room temperature for 2h to obtain a graphene oxide dispersion; weigh 25g of antioxidant Revonox 608 and pour it into 200mL of ethanol, heat the ethanol solution of high-temperature resistant antioxidant and graphene oxide dispersion respectively to 50°C, then, add the ethanol solution of the high-temperature resistant antioxidant to the graphene oxide dispersion dropwise within 0.5h at 50°C, and magnetically stir at 50°C for 5h at a speed of 800rpm, and then cool the mixed solution Pour into a centrifuge tube at room temperature, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com