Finned tube type multi-return-stroke low-nitrogen condensation gas evaporator

A finned tube type, multi-return technology, applied in the direction of steam generation, air heaters, steam boilers, etc., can solve the problems of gas leakage, many fault points, inconvenient installation of heat exchangers, etc., to reduce the emission of nitrogen oxides , meet the needs of installation and use, and solve the effect of condensed water problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

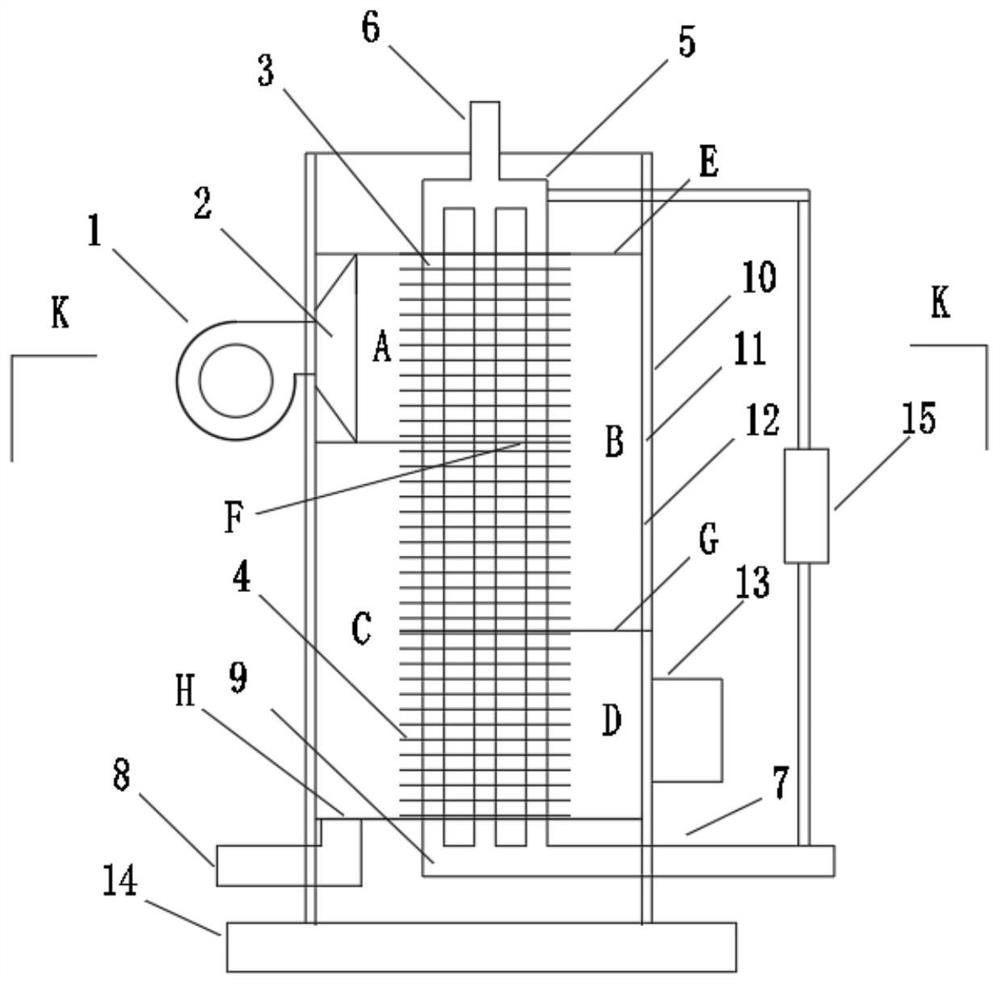

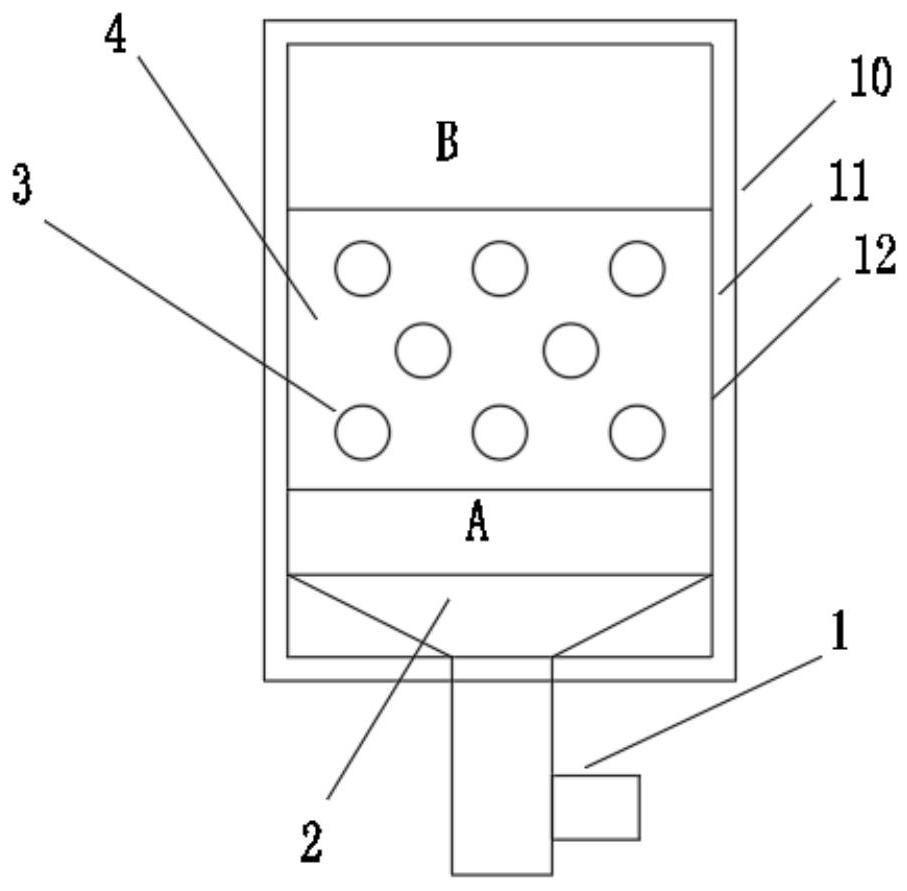

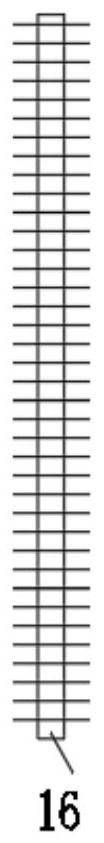

[0027] The first embodiment of the present invention provides a finned tube multi-pass low-nitrogen condensing gas evaporator, see figure 1 , which includes: burner fan 1, burner combustion head 2, water pipe or steam pipe 3, fins 4, steam or hot water confluence pipe 5, steam or hot water outlet pipe 6, water supply pipe 7, exhaust gas condensation Water pipe 8, water confluence pipe 9, furnace outer wall 10, furnace wall insulation layer 11, furnace inner wall 12, smoke exhaust pipe 13, furnace body base 14, water level gauge 15.

[0028] For the convenience of description, the end partitions of the flue gas chamber are defined as the top flue gas partition E and the bottom flue gas partition H, and the partitions in the flue gas chamber are def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com