Method for judging reaction endpoint of diacetyl guanine and controlling quality of finished product

A technology of diacetylguanine and reaction end point, applied in the direction of comprehensive factory control, measuring device, color/spectral characteristic measurement, etc., can solve the problem of no effective method for reaction end point control and finished product quality control, difficulty in end point control and finished product quality, purine Problems such as insoluble ring structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for diacetylguanine reaction endpoint judgment and finished product quality control, comprising the following steps:

[0024] Step (1): Using guanine as a starting material, using a mixture of acetic anhydride and acetic acid as an acylating reagent and solvent, under the action of a catalyst, heat up to 129 degrees, after 18 hours of acylation reaction, take a small amount of reaction solution, and cool down to 20- 50°C, filter to obtain diacetylguanine filter cake, wash with a small amount of acetic acid or acetic anhydride, and filter dry to obtain batches of diacetylguanine wet product 2005008 and 2005009.

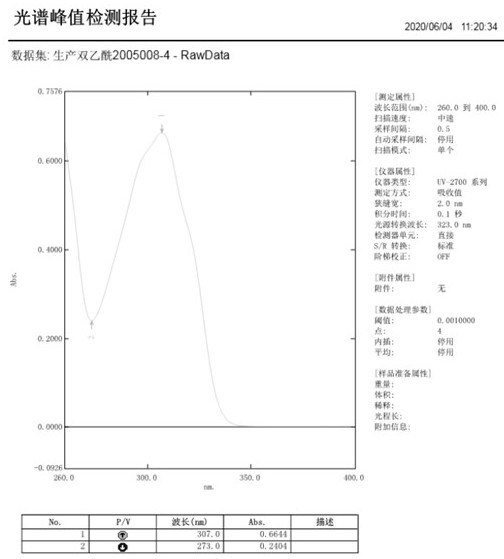

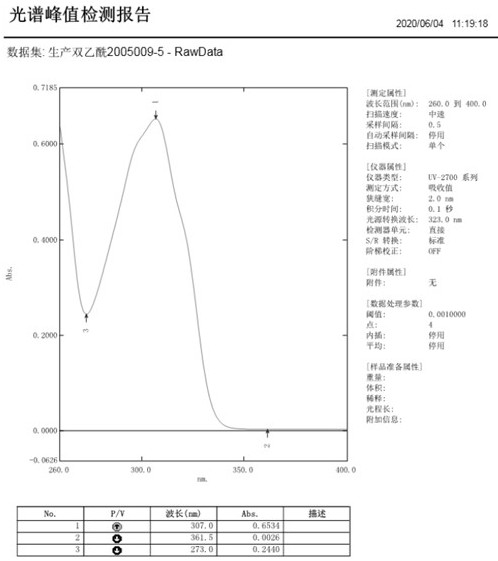

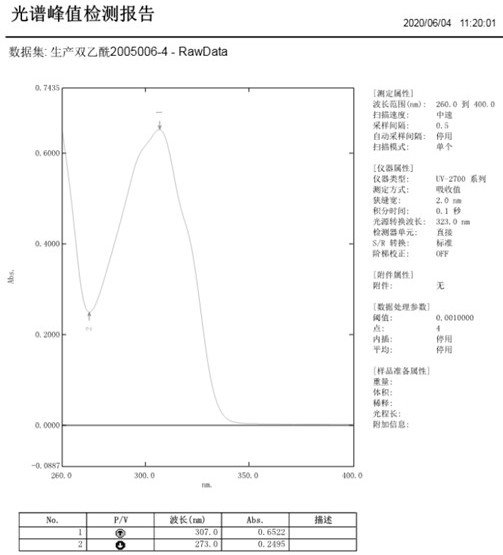

[0025] Step (2): use DMSO to prepare the 0.2-0.7 absorbance clarification solution allowed by UV spectrophotometry, detect the absorbance value at 307nm and 270nm with a UV spectrophotometer, or carry out 250-350 band scanning, calculate two kinds of wavelengths (wave peak and trough) absorbance ratio

[0026] Step (3): Use the same method to detect th...

Embodiment 2

[0030] Step (1): Using guanine as the starting material, using acetic anhydride and acetic acid mixture as the acylating reagent and solvent, the next batch of medium-quality diacetylguanine samples, and another batch of guanine control (Zhongjian Hospital), self-made monoacetylguanine control (purity greater than 99%).

[0031]

[0032] Step (2): Prepare the experimental solution (double sample) with the following concentration with DMSO:

[0033] Step (3): Dilute the above solution with DMSO until the absorbance of the solution is between 0.2-0.7, scan at 250-350nm, calculate the ratio of peak 306 to trough 273nm, and obtain the working curve, see Figure 8 and Figure 9 :

[0034] Available: guanine 0, 1%, 2%, 3%, 4%, 5% experimental diacetylguanine sample solution ultraviolet detection 306 / 273nm absorbance ratio (dual sample detection balance is good).

[0035] Diacetylguanine sample solutions containing 0, 1%, 2%, 3%, 4%, and 5% of monoacetylguanine were detected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com