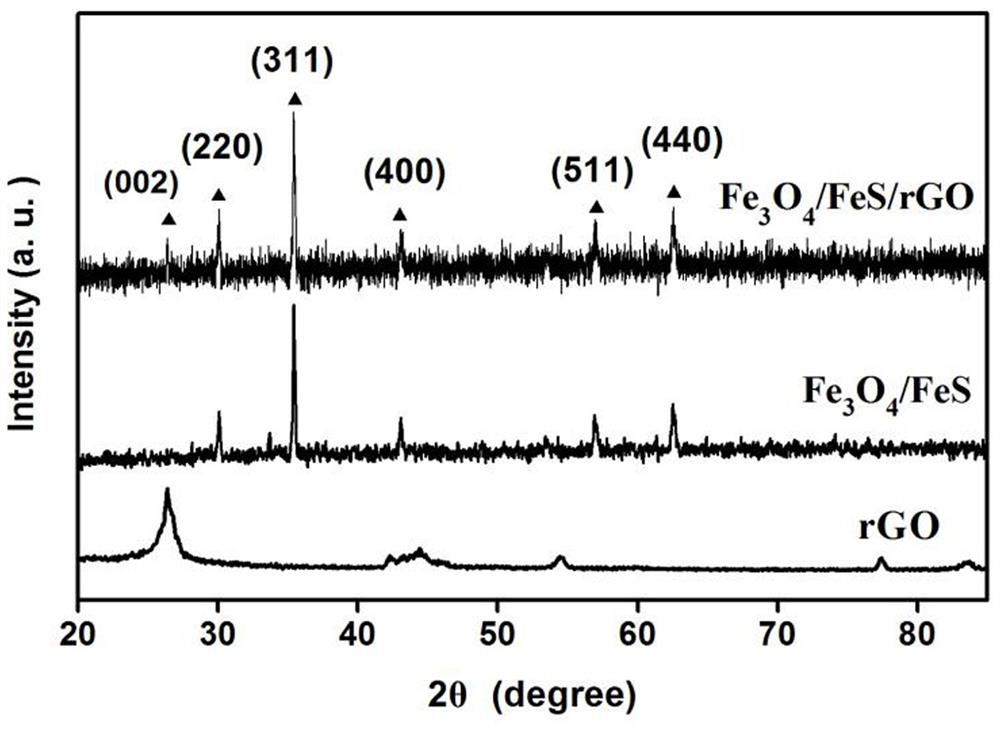

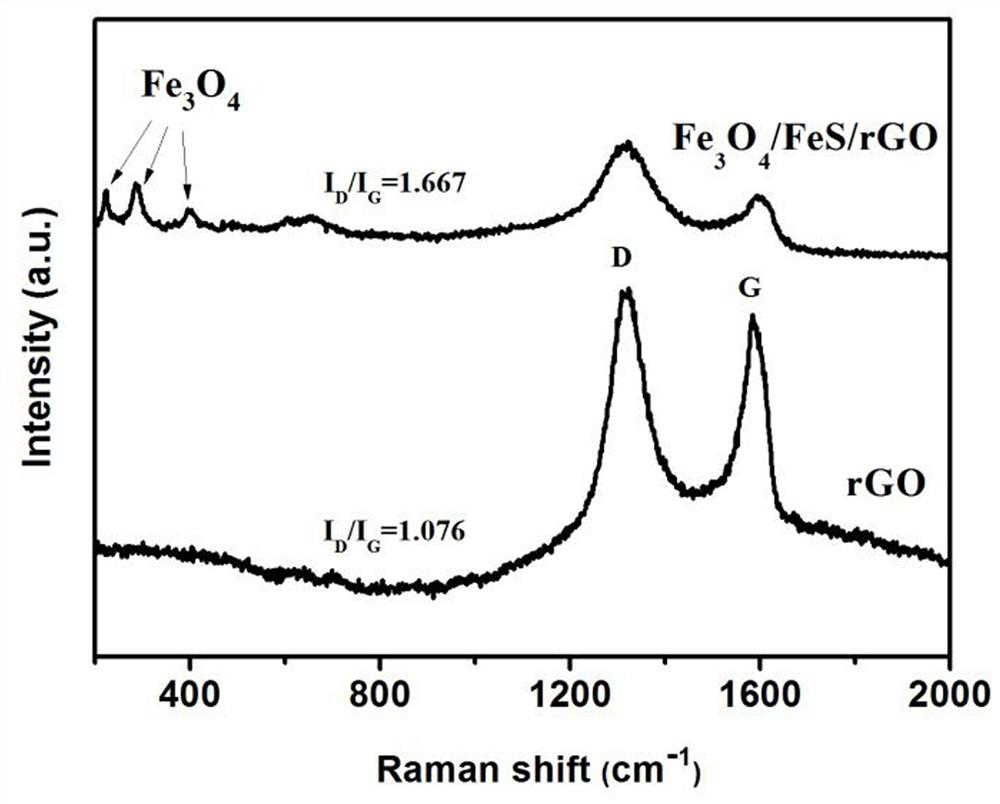

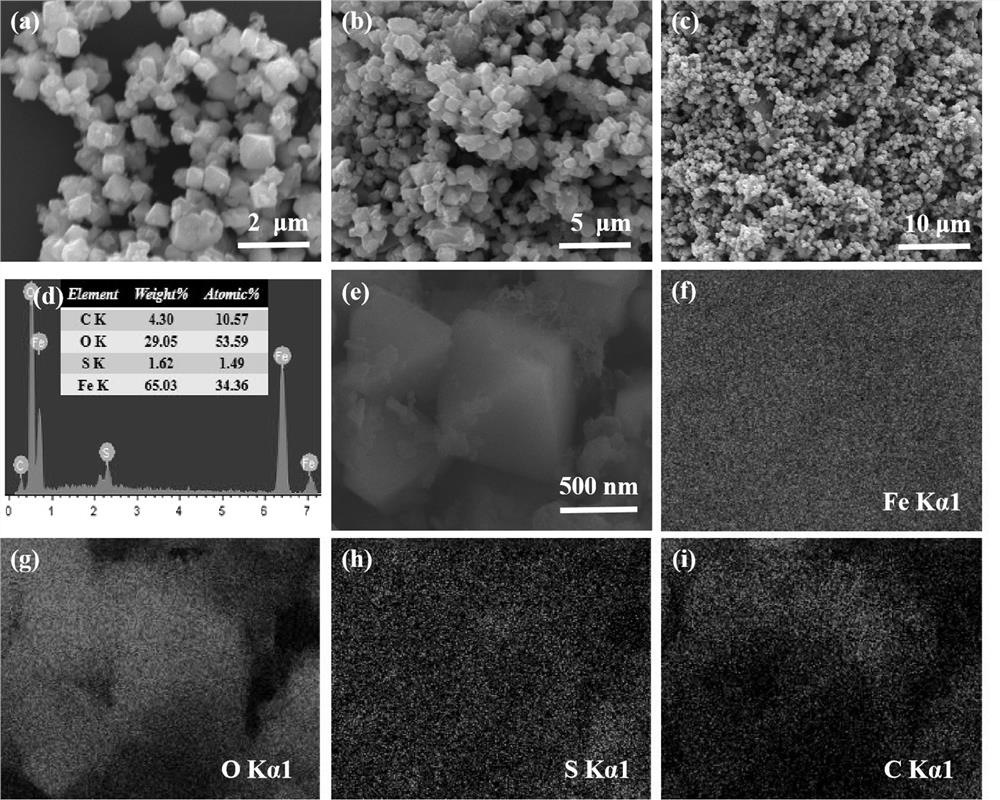

Three-dimensional cross-linked composite material Fe3O4/FeS/rGO as well as preparation method and application thereof

A composite material, three-dimensional cross-linking technology, applied in active material electrodes, electrical components, electrochemical generators, etc., can solve problems such as volume expansion, and achieve the effects of slowing volume expansion, preventing agglomeration, and improving electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The three-dimensional cross-linked composite material Fe of the present embodiment 3 o 4 / FeS / rGO preparation method, the steps are as follows:

[0035] (1) Under the condition of ultrasonic stirring, Fe(NO 3 ) 3 9H 2 O and 0.047g / mL of urotropine in deionized aqueous solution, then Fe(NO 3 ) 3 The solution was slowly added dropwise to the urotropine solution to obtain a mixed solution Ⅰ;

[0036] (2) Add 0.01 g of sublimed sulfur and 0.5 g of graphene oxide dispersion (10 mg / 1 g) to the mixed solution I prepared in step (1) respectively, and ultrasonically mix to obtain mixed solution II;

[0037] (3) Pour the mixed solution II of step (2) into the reaction kettle, raise the temperature from room temperature to 160°C, keep it warm for 10 hours, cool to room temperature after the reaction, wash the product until neutral, and dry it in an oven at 60°C for 12 hours to obtain Solid product I;

[0038] (4) The solid product I of step (3) was heated to 500°C at a hea...

Embodiment 2

[0044] The three-dimensional cross-linked composite material Fe of the present embodiment 3 o 4 / FeS / rGO preparation method, the steps are as follows:

[0045] (1) Under the condition of ultrasonic stirring, Fe(NO 3 ) 3 9H 2 O and 0.068g / mL of urotropine in deionized aqueous solution, then Fe(NO 3 ) 3 The solution was slowly added dropwise to the urotropine solution to obtain a mixed solution Ⅰ;

[0046] (2) Add 0.01 g of sublimed sulfur and 2 g of graphene oxide dispersion (10 mg / 1 g) to the mixed solution I prepared in step (1) respectively, and ultrasonically mix to obtain mixed solution II;

[0047] (3) Pour the mixed solution II of step (2) into the reaction kettle, raise the temperature from room temperature to 160°C, keep it warm for 10 hours, cool to room temperature after the reaction, wash the product until neutral, and dry it in an oven at 60°C for 12 hours to obtain Solid product I;

[0048] (4) The solid product I of step (3) was heated to 500°C at a heati...

Embodiment 3

[0050] The three-dimensional cross-linked composite material Fe of the present embodiment 3 o 4 / FeS / rGO preparation method, the steps are as follows:

[0051] (1) Under the condition of ultrasonic stirring, Fe(NO 3 ) 3 9H 2 O and 0.068g / mL of urotropine in deionized aqueous solution, then Fe(NO 3 ) 3 The solution was slowly added dropwise to the urotropine solution to obtain a mixed solution Ⅰ;

[0052] (2) Add 0.15 g of sublimed sulfur and 1 g of graphene oxide dispersion (10 mg / 1 g) to the mixed solution I prepared in step (1) respectively, and ultrasonically mix to obtain mixed solution II;

[0053] (3) Pour the mixed solution II of step (2) into the reaction kettle, raise the temperature from room temperature to 160°C, keep it warm for 10 hours, cool to room temperature after the reaction, wash the product until neutral, and dry it in an oven at 60°C for 12 hours to obtain Solid product I;

[0054] (4) The solid product I of step (3) was heated to 500°C at a heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com