Sintering flue gas dense-phase semi-dry desulfurization and denitrification device and process

A semi-dry desulfurization and sintering flue gas technology, which is applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of dry raw material performance and high economic cost, high investment cost, and heavy burden on enterprises, and achieve Simple structure, low investment and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

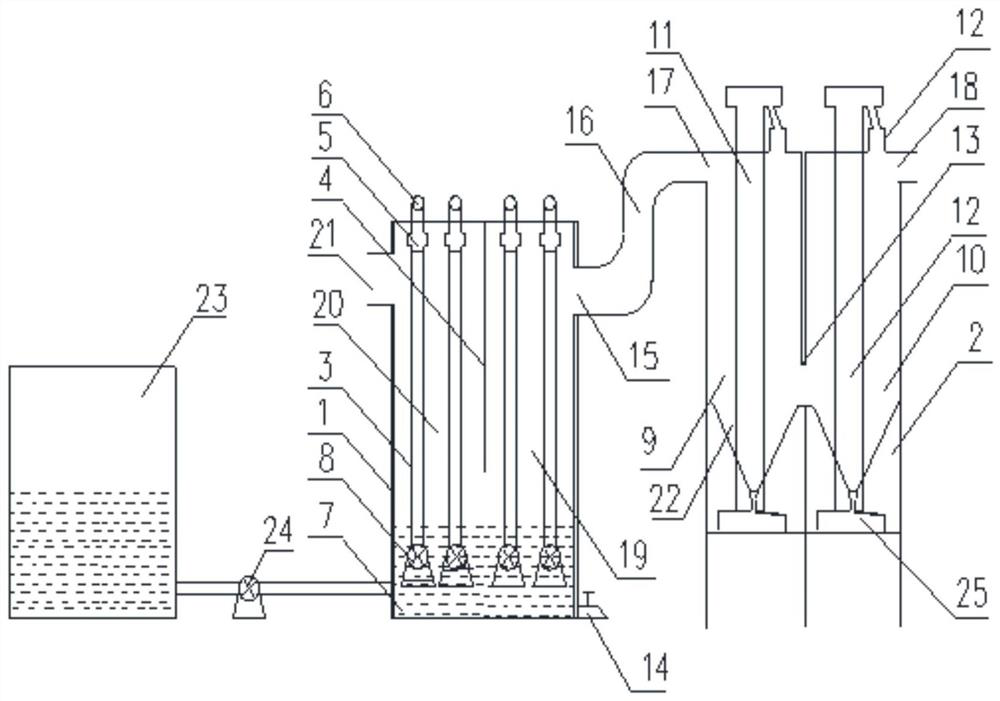

[0039] When the sintering machine is in full production, a sinter flue gas dense phase semi-dry desulfurization and denitrification process includes flue gas oxidation process, sulfur dioxide and nitrogen oxide absorption process, and discharge process of absorption by-products. The specific steps are:

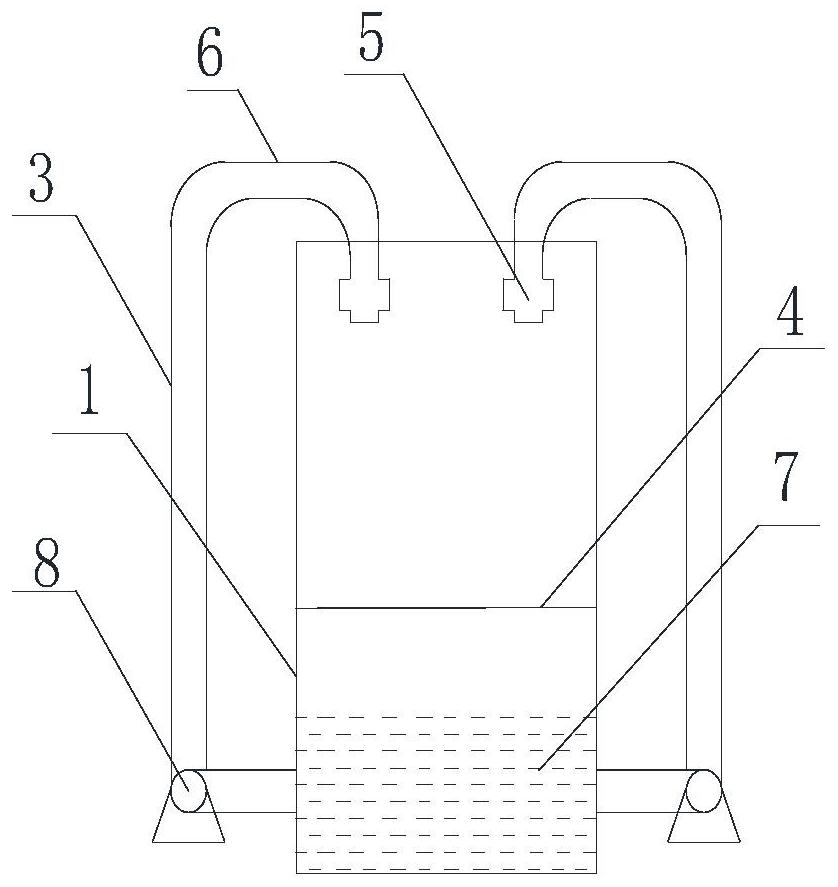

[0040] Before starting the oxidation chamber 1, turn on the oxidation and denitration agent pump 24, pump the oxidation and denitration agent in the oxidation and denitration agent storage tank 23 into the circulation pool (7) of the oxidation chamber 1, and keep the liquid level in the circulation pool 7 at 1200 mm;

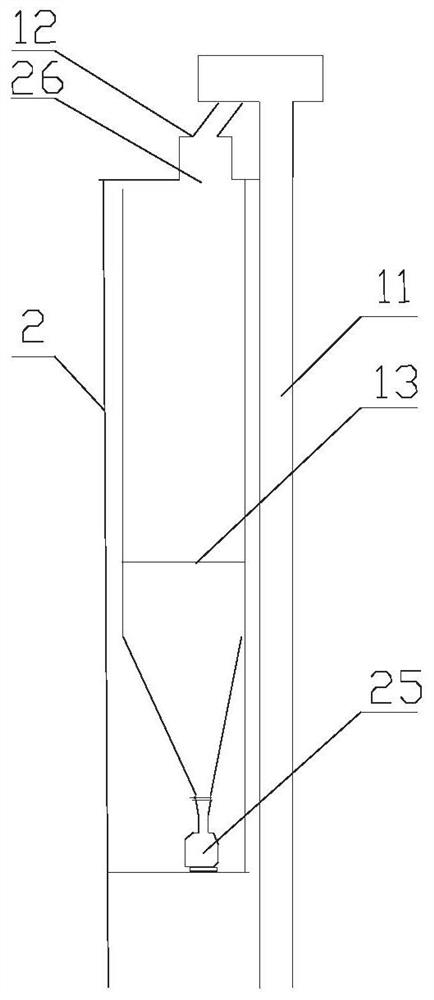

[0041] Before starting the oxidation chamber 1, the absorbent is transported from the ash hopper 22 at the bottom of the absorption chamber 2 to the bottom of the bucket elevator 11 through the zipper machine 28, and then vertically transported to the absorbent humidifier 12 on the top of the absorption chamber 2 through the bucket elevator 11, and passed thro...

Embodiment 2

[0054] During the start-up process of the sintering machine, a gas-dense phase semi-dry desulfurization and desulfurization process for sintering flue, including flue gas oxidation process, sulfur dioxide and nitrogen oxide absorption process, and discharge process of absorption by-products, the specific steps are:

[0055] Before starting the oxidation chamber 1, turn on the oxidation and denitration agent pump 24, pump the oxidation and denitration agent in the oxidation and denitration agent storage tank 23 into the circulation pool (7) of the oxidation chamber 1, and keep the liquid level in the circulation pool 7 at 1200 mm;

[0056] Before starting the oxidation chamber 1, the absorbent is transported from the ash hopper 22 at the bottom of the absorption chamber 2 to the bottom of the bucket elevator 11 through the zipper machine 28, and then vertically transported to the absorbent humidifier 12 on the top of the absorption chamber 2 through the bucket elevator 11, an...

Embodiment 3

[0069] During the shutdown process of the sintering machine, a sintering flue gas dense phase semi-dry desulfurization and denitrification process includes flue gas oxidation process, sulfur dioxide and nitrogen oxide absorption process, and discharge process of absorption by-products. The specific steps are:

[0070] Before starting the oxidation chamber 1, turn on the oxidation and denitration agent pump 24, pump the oxidation and denitration agent in the oxidation and denitration agent storage tank 23 into the circulation pool (7) of the oxidation chamber 1, and keep the liquid level in the circulation pool 7 at 1300 mm;

[0071] Before starting the oxidation chamber 1, the absorbent is transported from the ash hopper 22 at the bottom of the absorption chamber 2 to the bottom of the bucket elevator 11 through the zipper machine 28, and then vertically transported to the absorbent humidifier 12 on the top of the absorption chamber 2 through the bucket elevator 11, and pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com