Ultrasonic full-degradable biomass agricultural film production line system

An ultrasonic and production line technology, which is applied in the field of ultrasonic fully degradable biomass agricultural film production line system, can solve the problems of agricultural film distortion, affecting the service life of bearings, and large energy consumption, so as to improve the water filtration performance, improve the fineness, and improve the fineness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

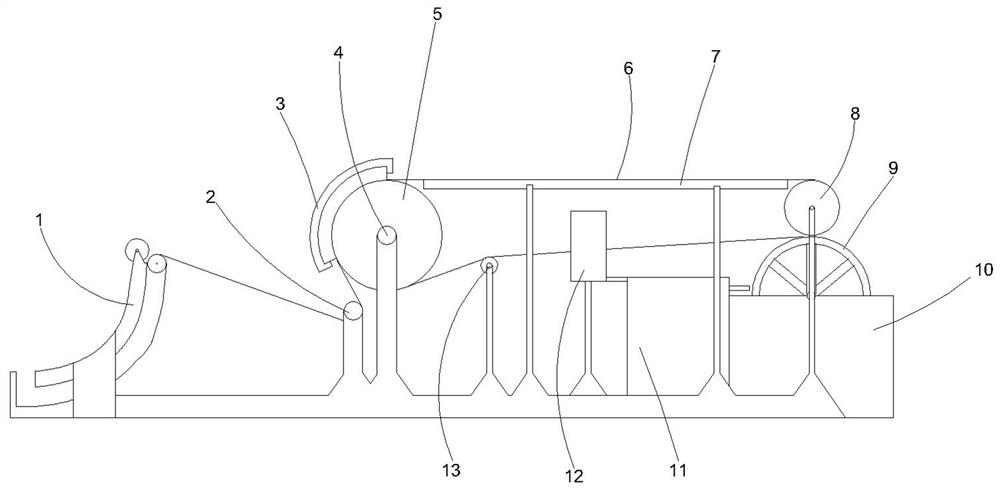

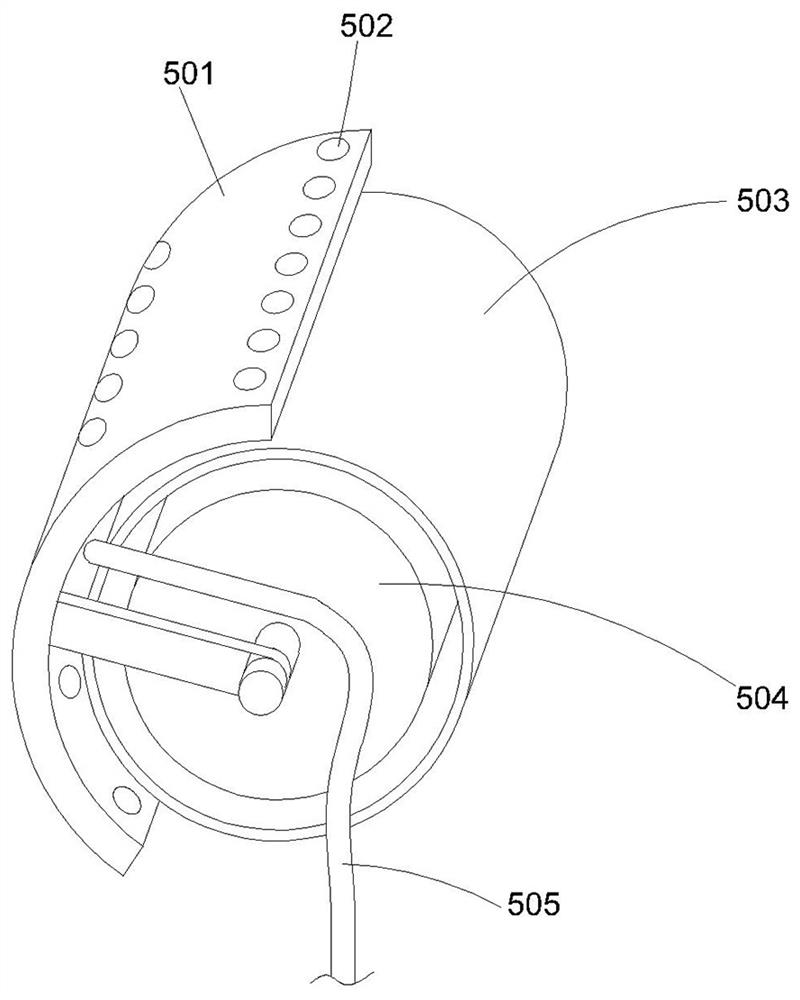

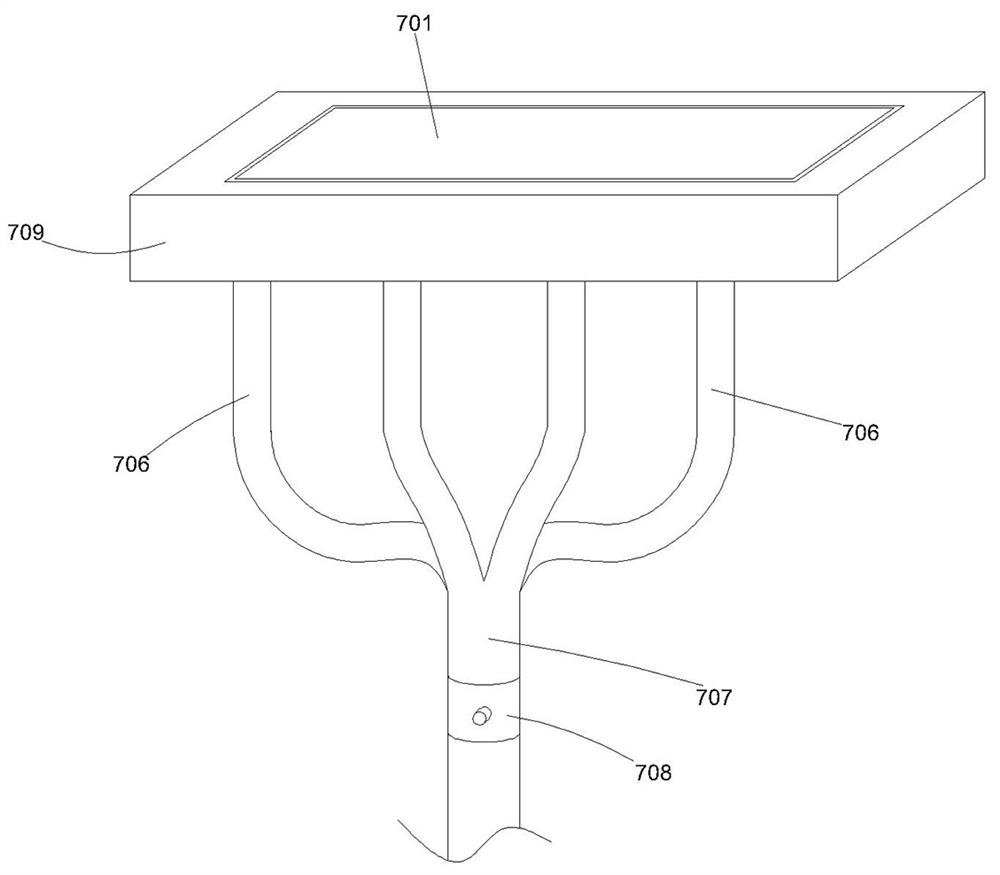

[0045] Ultrasonic fully degradable biomass agricultural film production line system, its structure is as follows Figure 1-Figure 16As shown, it includes a dehumidification system matched with the production line system, and the dehumidification system is connected with a PLC control system; the production line system includes a headbox 11 and a drying device 5, and the headbox 11 is provided with a pulp inlet and a pulp outlet, and the outlet One side of the pulp mouth is provided with a white water tank 10, the white water tank 10 is provided with a mesh cage 9 matched with the headbox 11, the mesh cage 9 is provided with a felt cloth wheel 8, and the felt cloth wheel 8 is provided with a drying machine. The felt cloth 6 matched with the device 5, the side of the drying device 5 away from the felt cloth wheel 8 is provided with an agricultural film collection device 1; the pulp inlet is provided with a pulp inlet pipe 1205, and the end of the pulp inlet pipe 1205 is far away ...

Embodiment 2

[0052] The ultrasonic fully degradable biomass agricultural film production line system differs from the first embodiment in that: the cage fixing cylinder 901 is provided with interconnected overflow grooves and non-slip particle layers.

Embodiment 3

[0054] The difference between the ultrasonic fully degradable biomass agricultural film production line system and Example 1 is that the rolling ring 903 includes a pair of semi-rolling rings, one end of the half-rolling ring is provided with a connecting protrusion, and the other end is provided with a connecting protrusion. The matching connecting grooves, connecting grooves and connecting protrusions are provided with connecting screw holes, and through the cooperation between the connecting protrusions and connecting grooves of the adjacent half-rolling rings, the connecting screw holes are fixed with screws. Achieving detachable installation from rolling ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com