Method for providing high-purity and high-pressure hydrogen

A high-pressure hydrogen, high-purity technology, applied in container discharge methods, chemical instruments and methods, and equipment discharged from pressure vessels, etc., can solve the problems that hydrogen organic compounds are not suitable for direct use, and hydrogen is not easy to store and transport. The effect of reducing hydrogen partial pressure, reducing operating costs, and improving dehydrogenation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

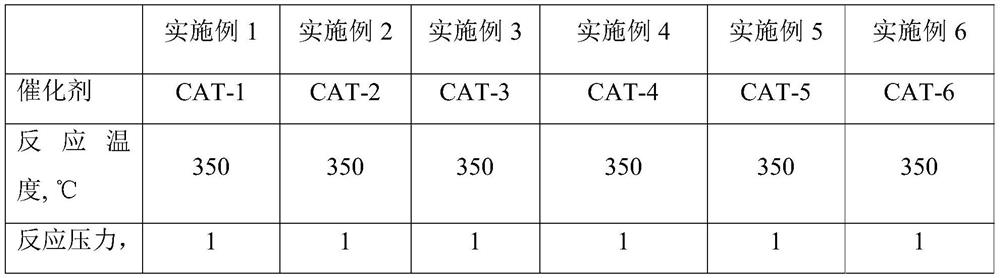

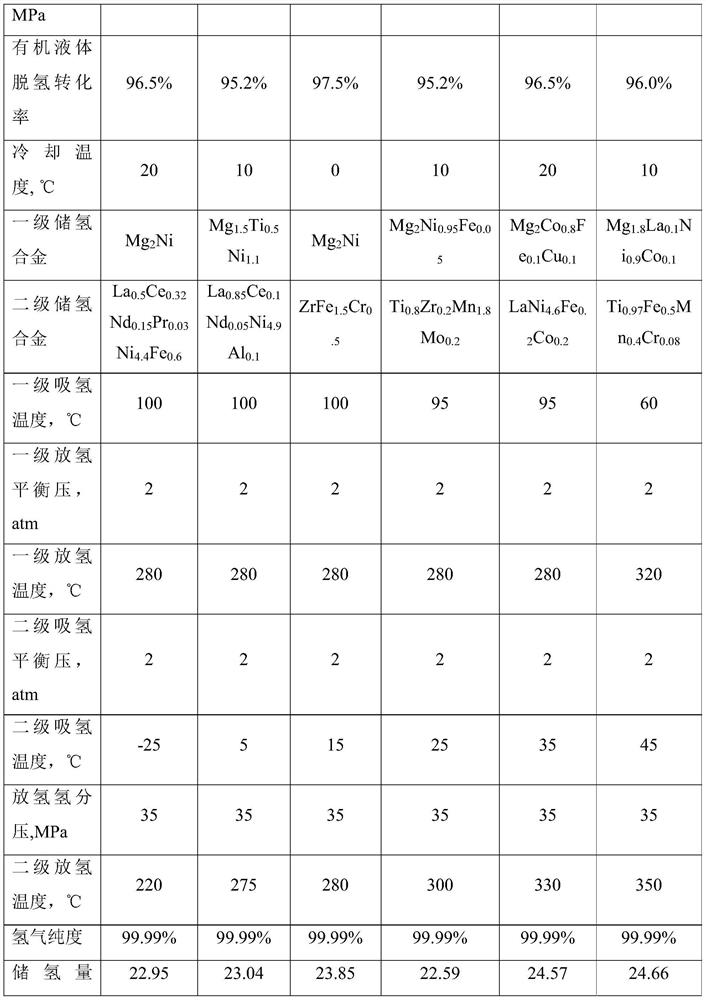

Examples

preparation example Construction

[0062] The preparation method of the hydrogen storage alloy is not particularly limited in the present invention, and it can be prepared by any existing method in the art. Preferably, the preparation method of the hydrogen storage alloy comprises the following steps:

[0063] 1) Weighing each raw material of the hydrogen storage alloy in a manner to achieve the composition of the hydrogen storage alloy and mixing;

[0064] 2) melting the material obtained by mixing in step 1), and then annealing.

[0065] The present invention has a wide range of options for the smelting methods and conditions, and various existing smelting methods and conditions are within the protection scope of the present invention. The smelting includes but not limited to electric furnace smelting and induction smelting. The electric furnace smelting and induction smelting have conventional illustrations in the field, and the present invention will not repeat them here.

Embodiment approach

[0066] According to a preferred embodiment of the present invention, the conditions of the smelting include: carrying out under vacuum or an inert atmosphere at a temperature of 1200-3000°C, preferably 1800-2200°C.

[0067] According to a preferred embodiment of the present invention, the smelting is carried out under vacuum, and the pressure of the smelting is 1×10 -5 -1×10 -3 Pa, preferably 0.5×10 -4 -5×10 -4 Pa.

[0068] According to a preferred embodiment of the present invention, the smelting is carried out under an inert atmosphere, and the smelting pressure is 0.5-1 bar, preferably 0.7-1 bar.

[0069]According to the present invention, preferably, the smelting time is 0.1-3 hours, more preferably 10-60 minutes.

[0070] The inert atmosphere may be provided by an inert gas, and the inert gas includes but not limited to at least one of argon, helium, and neon. Preferably, the inert atmosphere is provided by argon.

[0071] According to the method provided by the pre...

preparation example 1-1

[0102] SB powder was calcined at 500℃ for 4h to obtain carrier γ-Al 2 o 3 , named M-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com