Roof greening substrate

A roof greening and substrate technology, applied in planting substrate, culture medium, horticulture, etc., can solve the problems of nutrient loss, poor fertilizer retention ability, and only use cultivation substrate, etc., to achieve high organic content, rich nutrition, and good environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

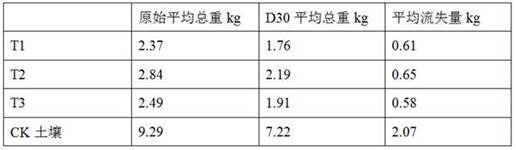

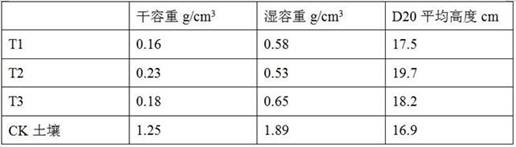

Examples

Embodiment 1

[0026] Collect meal waste, and use ordinary solid-liquid separation equipment to compress the liquid and solid through axial rotation so that the liquid and solid come out from different openings separately, and the residual oil will gradually decompose in a high-temperature environment. Obtain solid food waste with a solid content ≥ 90%. Mix 60 parts of solid meal waste, 25 parts of fungus residue, 20 parts of livestock and poultry manure and 35 parts of crop straw, adjust the carbon-nitrogen ratio to 40, and add 1.2wt% of high-temperature actinomycetes.

[0027] Carry out high-temperature fermentation: Make the fermentation raw materials into strips, with a bottom width of 2 meters, a height of 1.5 meters, and a strip length of not less than 5 meters. The fermentation temperature is above 75°C and the pile is turned over for the first time, and the pile is turned once every 3-5 days to maintain the pile. The temperature at 30cm below the body surface is not lower than 55°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com