Finished koji fermented soya bean spore hypha cleaning component for preparing high-quality fermented soya beans

A high-quality, tempeh technology, applied in food science and other directions, can solve the problems of poor cleaning effect and low cleaning efficiency of spore mycelium, and achieve the effects of strong reliability, novel structure and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

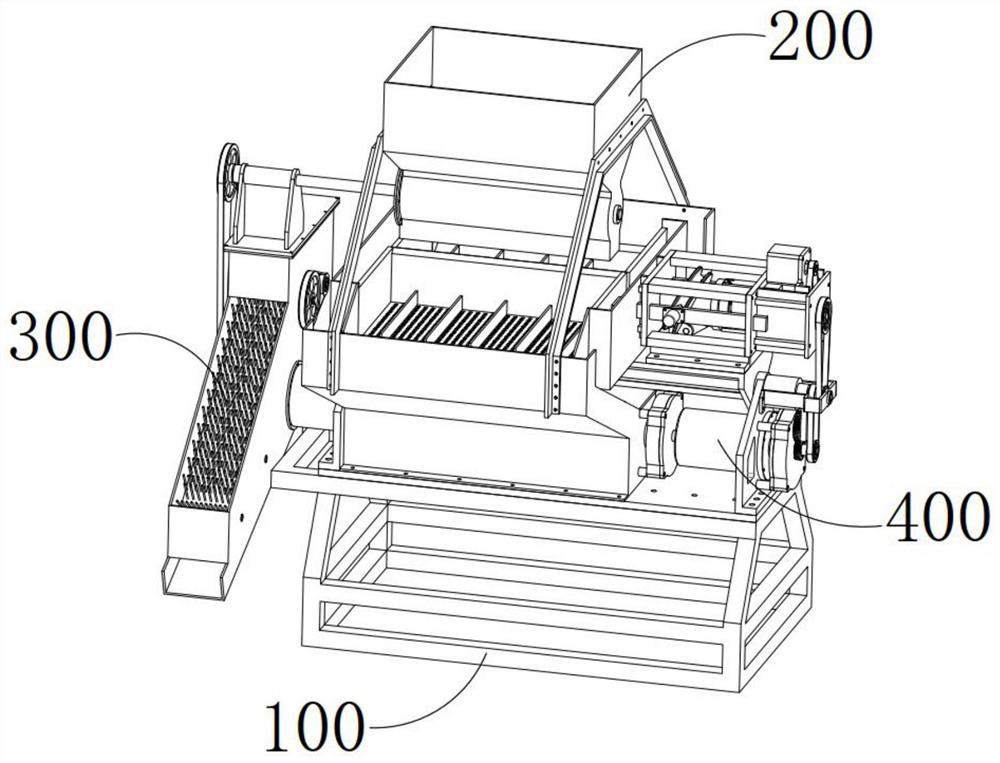

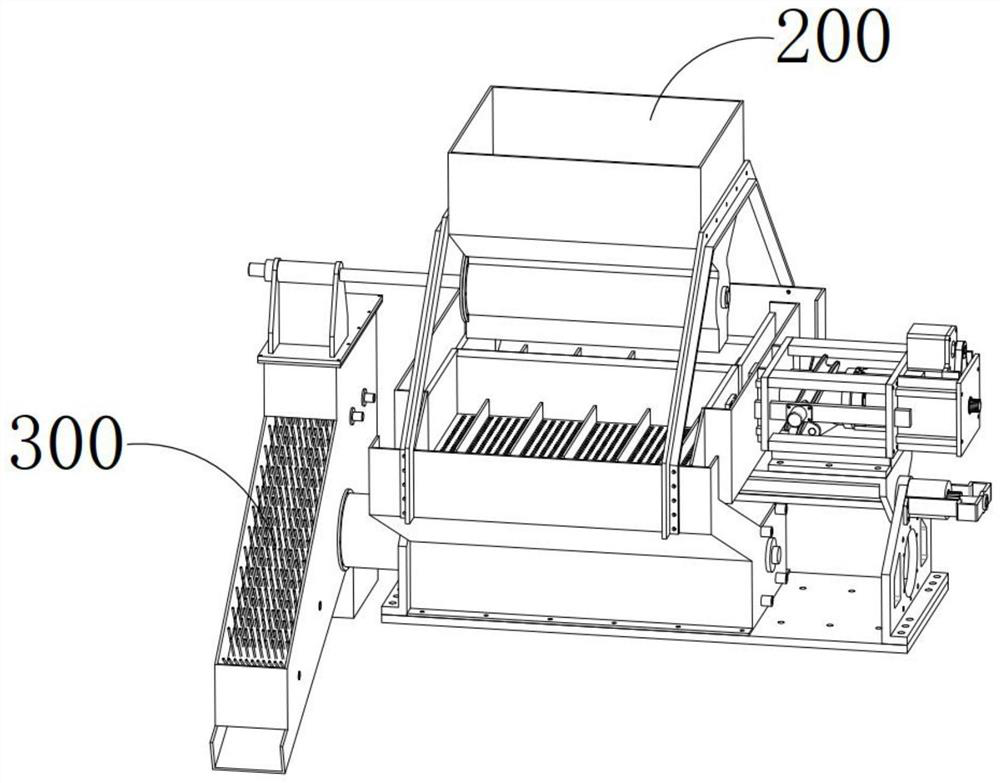

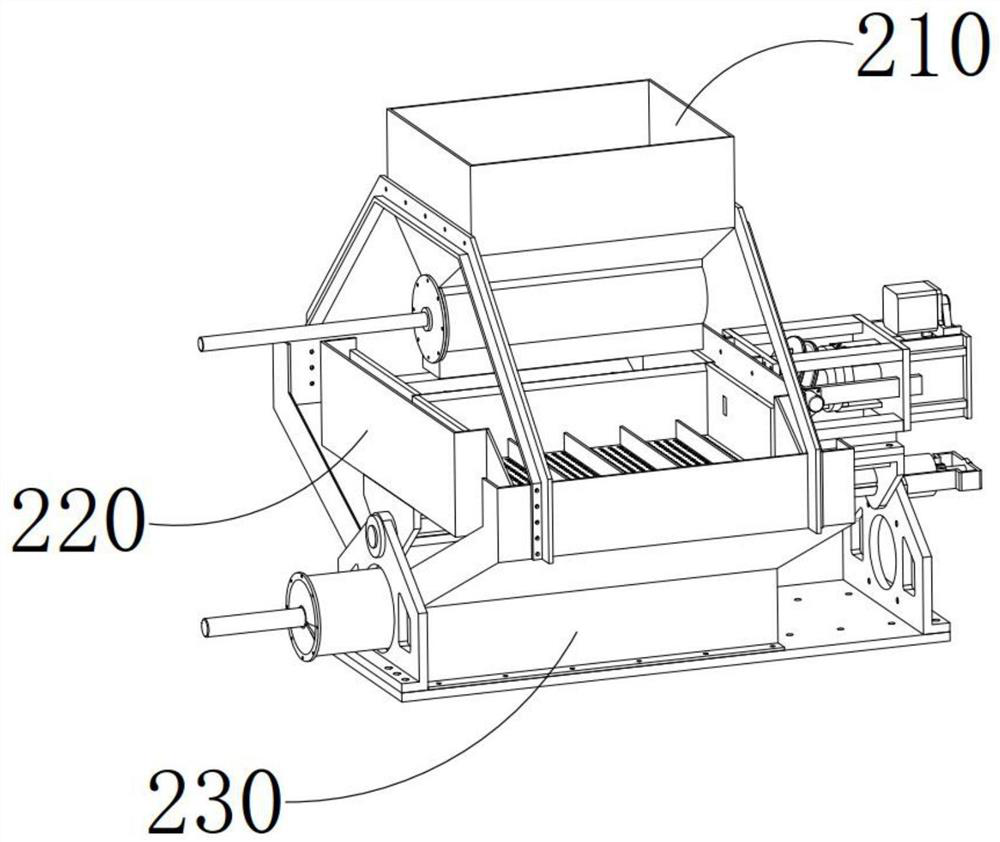

[0059] see Figure 1-33 , a double pendulum type tempeh spore mycelia cleaning machine, which includes a mounting frame 100, a detachment device 200, a cleaning device 300 and a power drive device 400, and the detachment device 200, the cleaning device 300 and the power drive device 400 are all fixedly installed on the mounting frame 100, the detachment device 200 includes a feeding mechanism 210, a reciprocating vibration mechanism 220, and a material receiving mechanism 230 arranged in sequence from top to bottom, the reciprocating vibration mechanism 220 is located between the feeding mechanism 210 and the material receiving mechanism 230, and the cleaning device 300 is located At one end of the mechanism 230, the feeding mechanism 210 is used to quantitatively and intermittently discharge the koji soya bean downwards to the reciprocating vibration mechanism 220, and the reciprocating vibration mechanism 220 is used to reciprocate the koji soya bean in the water area to sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com