Eutectic solvent, carbon quantum dots, preparation method and application

A technology of deep eutectic solvent and carbon quantum dots, which is applied in the direction of oxidative preparation of carboxylic acids, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high reaction cost, harsh reaction conditions, poor reaction selectivity, etc., and achieve high Chemical stability, short reaction time, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An embodiment of the present invention provides a deep eutectic solvent and carbon quantum dots,

[0035] The deep eutectic solvent is prepared from phenol and isoleucine with a molar ratio of 3:2, specifically comprising the following steps:

[0036] Mix 0.3mol (28.233g) of phenol and 0.2mol (26.234g) of isoleucine into a 100mL flask, raise the temperature to 95°C, and stir at a constant temperature of 25 rpm for 6 hours to make the system uniform and transparent, and obtain iso Leucine / phenol deep eutectic solvent A.

[0037] The method for preparing carbon quantum dots by using the above-mentioned isoleucine / phenol deep eutectic solvent A specifically includes the following steps:

[0038] Add the isoleucine / phenol deep eutectic solvent A into the crucible, heat to 450°C and roast it into a solid, grind it into powder, place it in a muffle furnace, and dry it at a constant temperature of 300°C for 4 hours to obtain carbon quantum dots A16.5g.

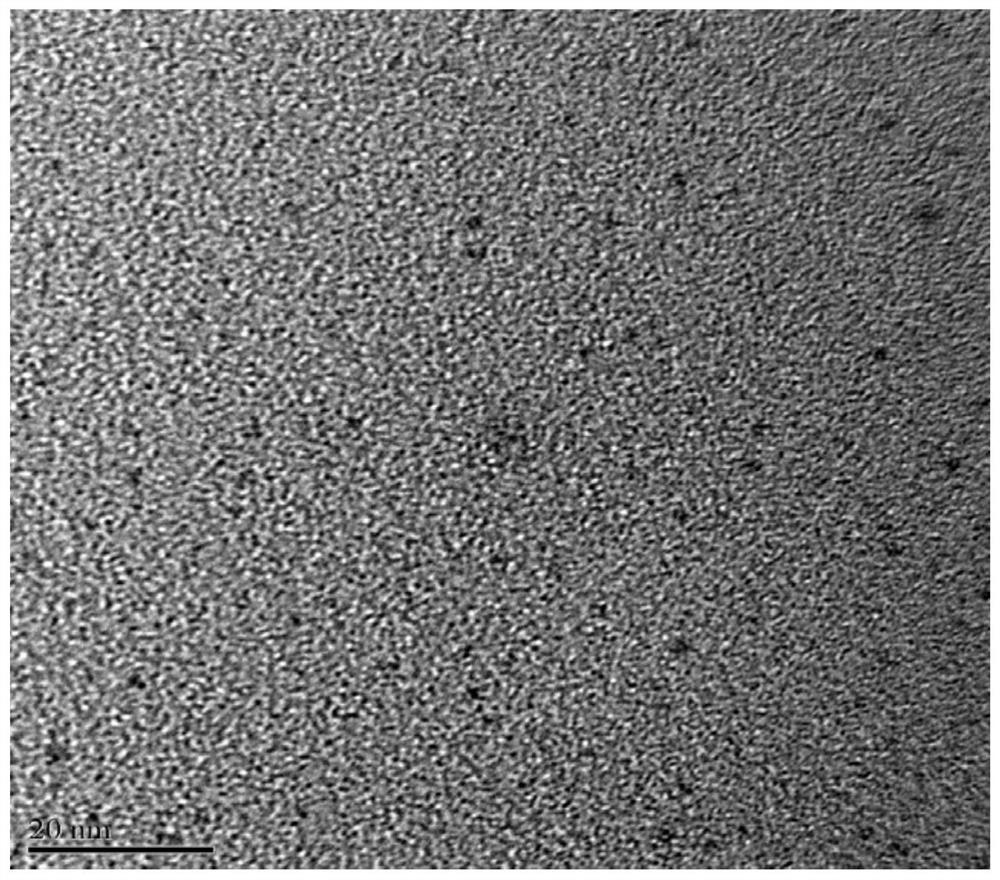

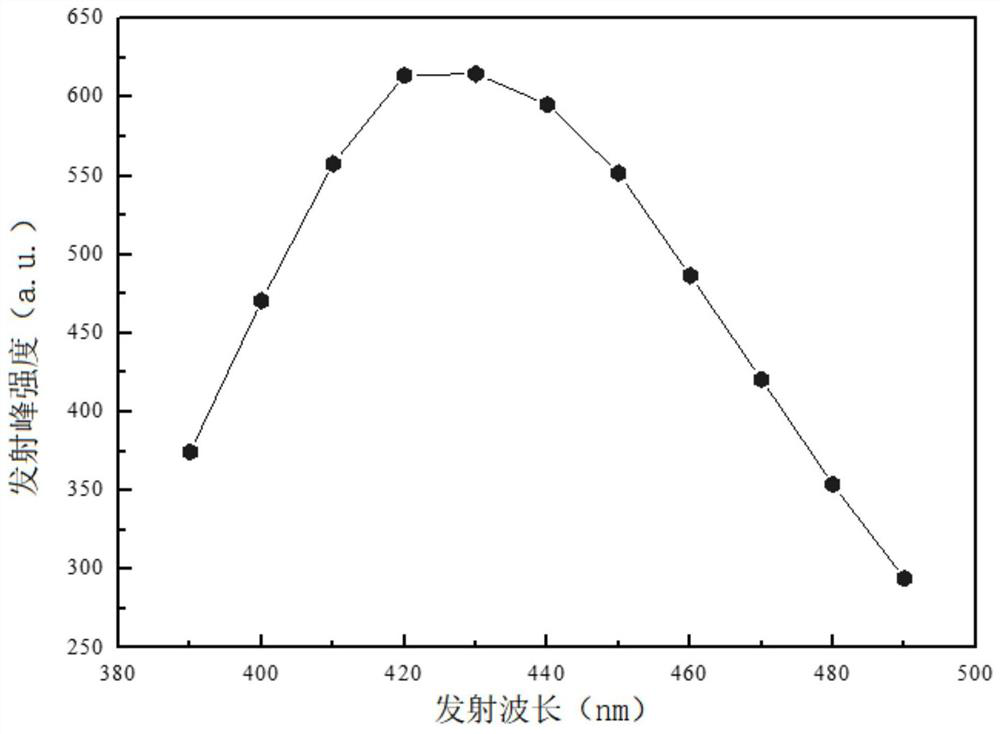

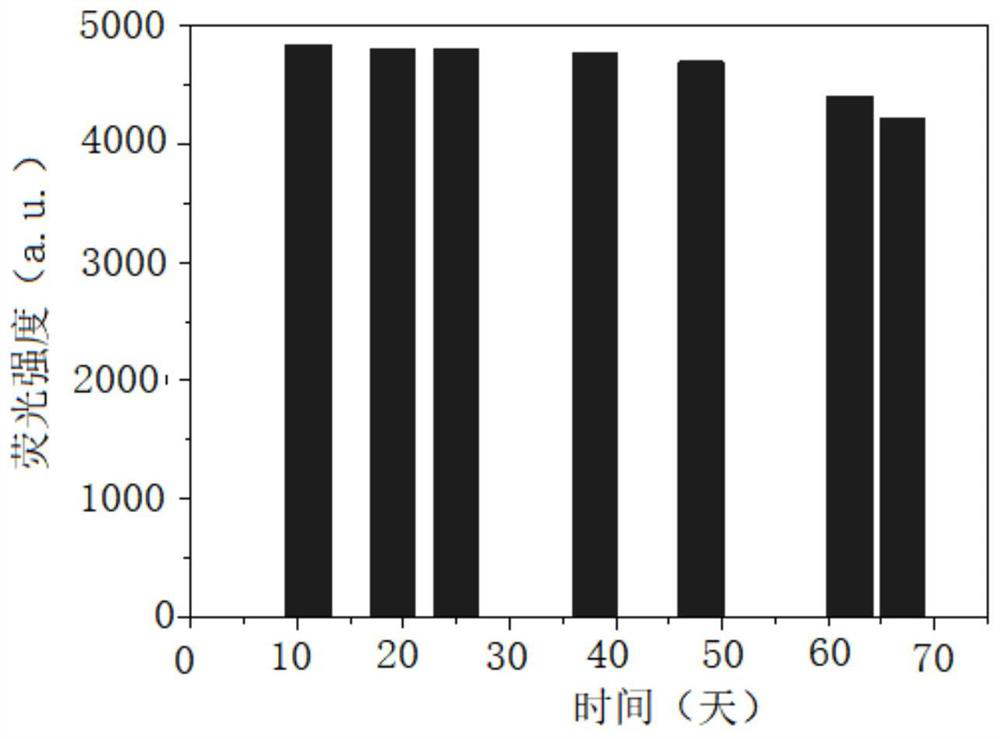

[0039] figure 1 Th...

Embodiment 2

[0043] An embodiment of the present invention provides a deep eutectic solvent and carbon quantum dots,

[0044] The deep eutectic solvent is prepared from cresol and glycine with a molar ratio of 1:2.5, specifically comprising the steps of:

[0045] Mix 0.2 mol (21.62 g) of cresol and 0.5 mol (37.535 g) of glycine into a 100 mL flask, raise the temperature to 110 ° C, and stir at a constant temperature of 25 rpm for 4 hours to make the system uniform and transparent to obtain glycine / formazine Phenolic eutectic solvent B.

[0046] The method for preparing carbon quantum dots by utilizing the above-mentioned glycine / cresol deep eutectic solvent B specifically includes the following steps:

[0047] Add the glycine / cresol deep eutectic solvent B into a crucible, heat it to 250°C and roast it into a solid, grind it into powder, place it in a muffle furnace, and dry it at a constant temperature of 180°C for 5 hours to obtain carbon quantum dots B19. 2g.

Embodiment 3

[0049]An embodiment of the present invention provides a deep eutectic solvent and carbon quantum dots,

[0050] The deep eutectic solvent is prepared from naphthol and glycine with a molar ratio of 1:0.23, specifically comprising the steps of:

[0051] Mix 0.4mol (57.6g) of naphthol and 0.09mol (6.87g) of glycine into a 100mL flask, raise the temperature to 100°C, and stir the reaction at a constant temperature of 25 rpm for 8 hours to make the system uniform and transparent to obtain glycine / naphthalene Phenol deep eutectic solvent C.

[0052] Utilize above-mentioned glycine / naphthol deep eutectic solvent C to prepare the method for carbon quantum dots specifically comprise the steps:

[0053] Add the glycine / naphthol deep eutectic solvent C into a crucible, heat it to 300°C and roast it into a solid, grind it into powder, place it in a muffle furnace, and dry it at a constant temperature of 150°C for 6 hours to obtain carbon quantum dots C19. 9g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com